Allen Engine PVBCS12 F Crankshaft Repair in Gambia

Price 1500 INR/ Square Inch

Allen Engine PVBCS12 F Crankshaft Repair in Gambia Trade Information

- Minimum Order Quantity

- 1 Square Inch

- Supply Ability

- 1 Square Inch Per Day

- Delivery Time

- 2-3 Days

About Allen Engine PVBCS12 F Crankshaft Repair in Gambia

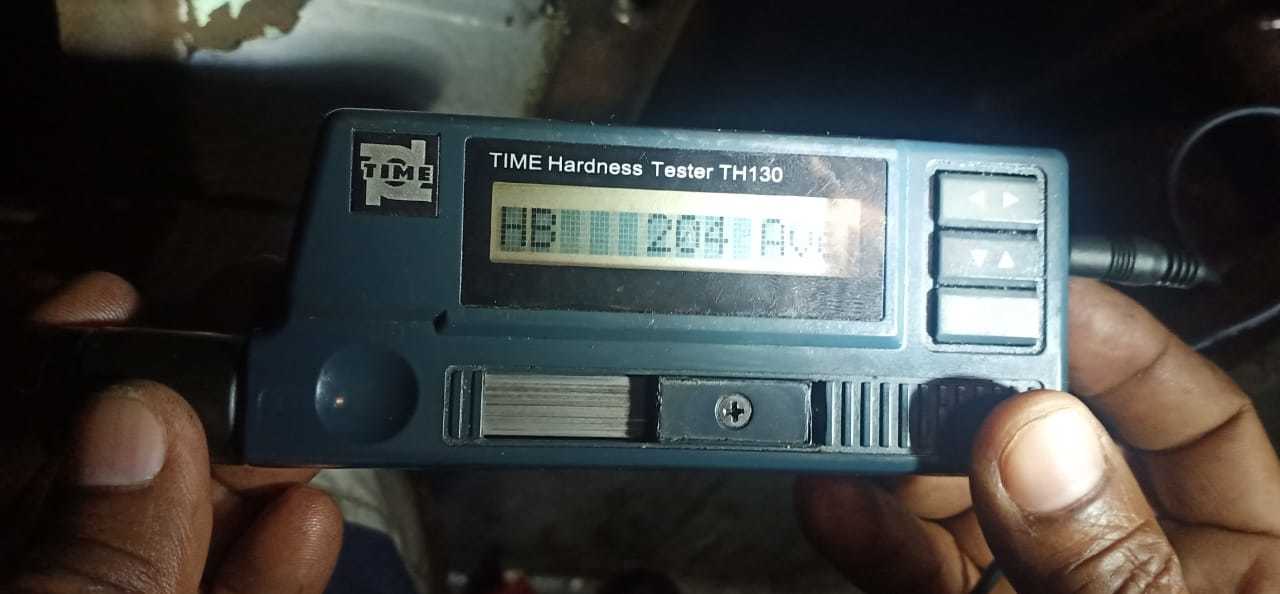

The grinding of crankpin is permissibleby the Allen Diesel as per following details:

|

BEARING SIZE |

ALLEN CODE NO. |

CRANKPIN DIAMETER |

|

Standard

0.020 in. undersize (0.5 mm.)

0.040 in. undersize (1.0 mm.)

0.060 in. undersize (1.52 mm.)

0.090 in. undersize (2.28 mm.)

|

SD 53816

D 56035

D 56036

D 56037

D 56038 |

7.498 in. 7.499 in.

7.478 in. 7.479 in.

7.458 in. 7.459 in.

7.438 in. 7.439 in.

7.408 in. 7.409 in. |

Training of our technicians

We have executed successfully repair of more than ten thousands crankshafts all over the world for all types of rotary equipments including steam turbines, rotor shafts, Diesel Engines, compressor, turbine, etc.

The technicians have been trained in our in-house training school where they are given constant training on how to improve the quality of services and execute the repairs in minimum time.

Ours is the only company in the world that can undertake the crankshaft grinding and crankshaft polishing while sailing of the vessel. No need of holding a vessel for crankshaft repairs.

We have been regularly executing the repairs of crankshaft, metal stitching of damaged engine components, rebabbitting in Madagascar, Oman, Qatar, Philippines, Bahrain, Srilanka, Bangladesh, Myanmar, Turkey, Nigeria, Greece, Saudi Arabia, UK, Dubai, Malta, Cyprus, Singapore, Malaysia, Colombia, Indonesia, Hong Kong, Spain, Netherlands, Dubai, Portugal, Estonia, Morocco, Belgium, Vietnam, Canada, Jordan, Libya, Kuwait, Egypt, Morocco, Yemen, Bahrain, Tunisia, Sudan, Oman, Algeria, UAE, Iraq.

For more information, contact us on raj.shahani@rapowersolutions.com or callus at +91-9582647131 or +919810012383

Enhanced Performance with Precision Ground Finish

Engineered for the Allen Engine series, the PVBCS12 F Crankshaft Repair features a precision ground surface that minimizes friction and wear. This ensures smoother engine operation and preserves engine integrity over the long term. Its tailored fit to OEM specifications makes it an ideal choice for both repair and upgrade needs.

Corrosion Resistance and Longevity

With corrosion-resistant materials and a robust design, this crankshaft repair solution excels in durability. Engineered to withstand Gambias varying environmental conditions, it delivers exceptional reliability and extends your engines service life, lowering the frequency and cost of replacements or repairs.

Expert Handling and Secure Packaging

Every unit is packaged using secure export techniques that protect the crankshaft during transit. Our products come ready for immediate dispatch, ensuring prompt delivery across Gambia. To guarantee peak performance and safety, professional installation by qualified technicians is advised.

FAQs of Allen Engine PVBCS12 F Crankshaft Repair in Gambia:

Q: How is the Allen Engine PVBCS12 F Crankshaft Repair installed?

A: Professional installation is recommended to ensure correct alignment, optimal function, and avoidance of engine damage. Our team or your trusted service technician can handle the installation using standard tools and procedures for the Allen Engine series.Q: What makes the surface finish of this crankshaft repair special?

A: The PVBCS12 F Crankshaft Repair is precision ground for a smooth surface. This enhances engine efficiency by reducing friction, which in turn promotes longevity and consistent performance.Q: When will my order be delivered in Gambia?

A: With ready stock availability and a streamlined export process, your order can be dispatched promptly for delivery anywhere in Gambia. Exact delivery times depend on your location, but we prioritize swift shipping to minimize downtime.Q: Where can I use this crankshaft repair kit?

A: This product is suitable for all engines within the Allen Engine series that require crankshaft repairs conforming to standard OEM dimensions. It is widely used across industries including automotive, marine, and machinery repair in Gambia.Q: What is the benefit of choosing this corrosion-resistant crankshaft repair?

A: Opting for our corrosion-resistant crankshaft repair extends your engines lifespan, reduces maintenance frequency, and ensures reliable performance even in harsh environments such as coastal or humid regions.Q: What is the process for exporting and securing the crankshaft repair?

A: We use secure, export-grade packaging to protect each unit from damage during transit. As a manufacturer and exporter based in India, we comply with international shipping standards and manage the entire process seamlessly from our facility to your destination in Gambia.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Crankshaft Repair Category

Onsite Crankshaft Grinding Machine

Price 300000 INR / Square Inch

Minimum Order Quantity : 1 , , Square Inch

Daihatsu DK20 Crankshaft Machining on site is possible

Price 1500 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

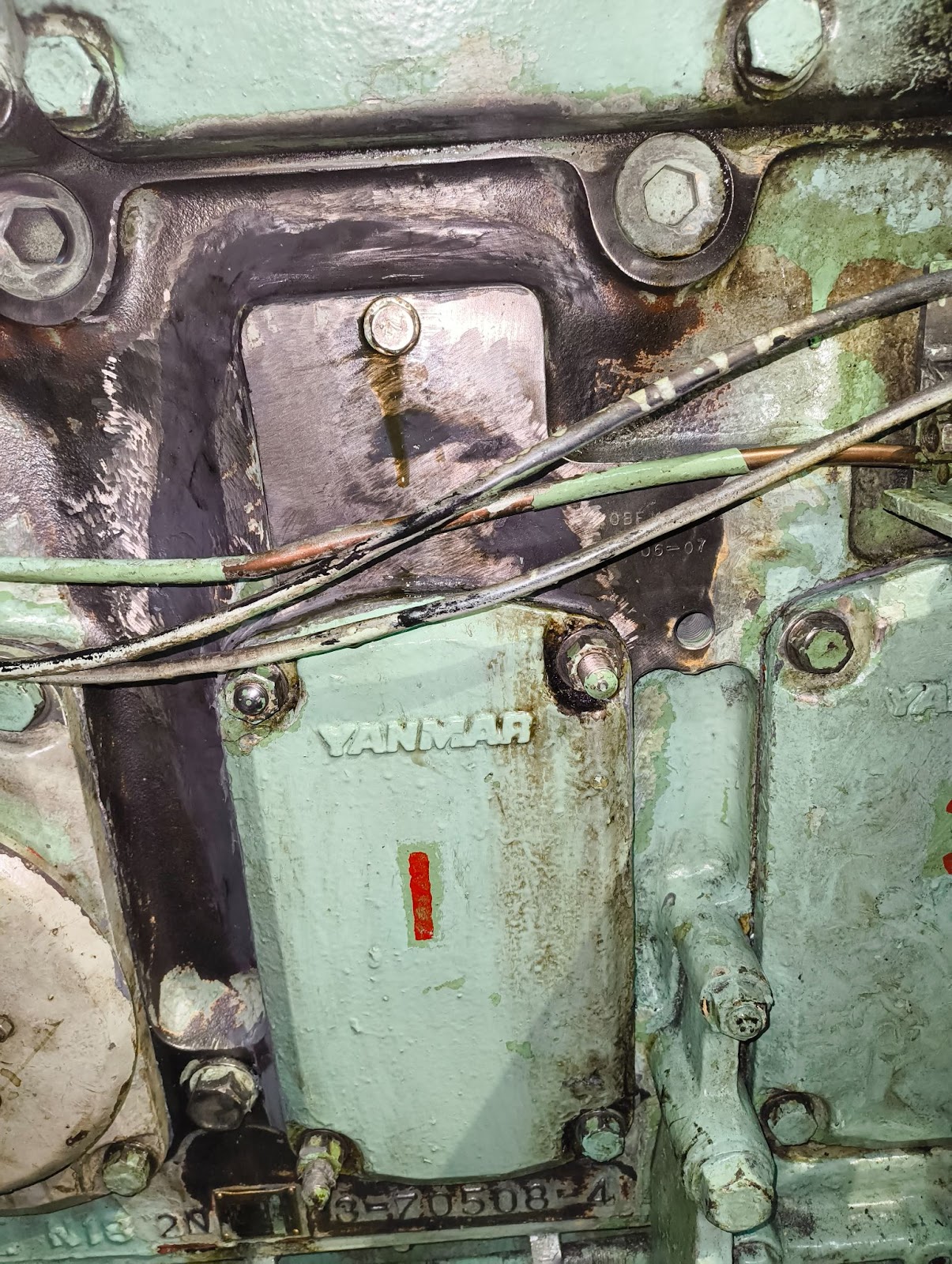

YANMAR 6N18L-SV Auxiliary Engine Crankshaft

Price 1000.0 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Yanmar Diesel Generator Model no. 8N280L-EV Crankshaft Repair

Price 1500 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS