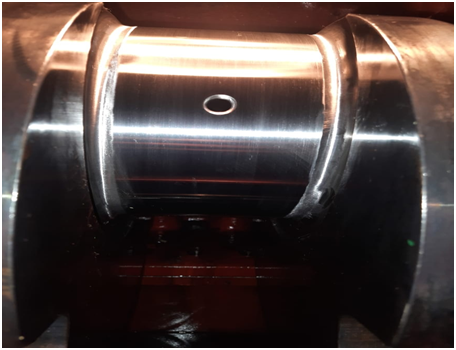

Crankshaft Polishing

Price 3900 INR/ Square Inch

MOQ : 1 Square Inch

Crankshaft Polishing Trade Information

- Minimum Order Quantity

- 1 Square Inch

- FOB Port

- Delhi India Port

- Supply Ability

- 1 Square Inch Per Day

- Delivery Time

- 2-3 Days

- Certifications

- ISO 9001:2015 SEPC

About Crankshaft Polishing

We provide crankshaft grinding, machining, and polishing all over the world at the very low price. Crankshaft polishing enhances the life of bearing and crankshaft manifolds. We are also manufacturers of crankshaft grinding machines and crankshaft polishing machines ranging from 35mm to 700mm in terms of diameter. The main structure of the crankshaft grinding machine is made up of high-quality titanium steel which has various properties like high vibration absorption,light weight, long service life etcAdvanced Crankshaft Polishing

Our crankshaft polishing service guarantees a superior mirror-like surface finish for various crankshaft materials, including steel, cast iron, and alloy. Depending on customer requirements, we offer both manual and automated polishing solutions powered by electric or pneumatic means, within a dust-controlled environment. With flexible operational speed and precision tolerances, our treatments meet the stringent needs of automotive, marine, and heavy-duty industrial applications.

Comprehensive Safety and Quality Controls

The polishing process takes place in workshops equipped with integrated water-based coolant systems, minimizing heat and dust. Adherence to safety protocols, including the use of recommended protective gear, ensures operator well-being. Each polished crankshaft undergoes inspection with surface profilometers to validate adherence to finish specifications and accuracy requirements.

FAQ's of Crankshaft Polishing:

Q: How is the crankshaft polishing process performed?

A: The process involves using emery, abrasive paper, or felt to polish the outer diameter of the crankshaft, either manually or with automated equipment. Workshops are equipped with electric or pneumatic power sources and feature integrated water-based coolant for precise operation and dust control.Q: What materials are compatible with your crankshaft polishing service?

A: We polish crankshafts made from steel, cast iron, and various alloys, ensuring a consistent mirror-like finish and adherence to industrial grade standards for different industry applications.Q: When is crankshaft polishing recommended?

A: Crankshaft polishing is advised during engine overhauls, maintenance, or before assembly to achieve optimal surface finish and accuracy, which helps enhance engine performance and longevity.Q: Where is the crankshaft polishing service provided?

A: We offer both on-site and in-house polishing for clients throughout India, catering to automotive, marine, and heavy-duty industries as an exporter, manufacturer, supplier, and service provider.Q: What safety measures are implemented during polishing?

A: Operators are advised to wear appropriate protective gear, and the workshops are dust-controlled with integrated coolant systems. These practices safeguard workers against particulates and heat-related risks.Q: What are the benefits of post-polishing surface inspection?

A: Each crankshaft is verified with a profilometer to ensure the surface finish meets specified accuracy (0.01 mm), offering assurance of quality and reliability for high-performance requirements.Q: Is customization available for the crankshaft polishing process?

A: Yes, we provide customization tailored to specific crankshaft sizes, material types, and finish requirements. Customers can request modifications as per unique project needs.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Crankshaft Polishing Category

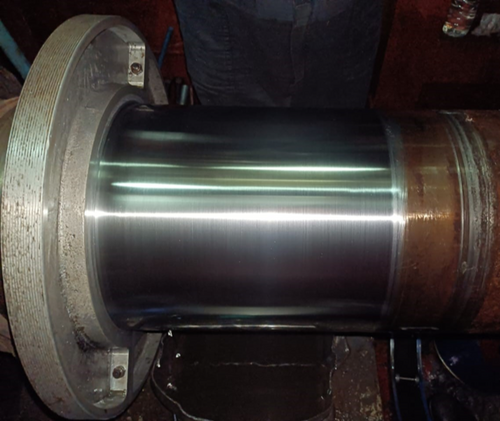

On Site Grinding and Polishing of Wartsila Vasa 32LN Engine crankshaft

Price 16000 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS