Cylinder Liner/ Engine Block/ Crack Repair of MAN Main Engine/ Metal Lock and Metal Stitching

Price 122018 INR/ Square Inch

MOQ : 1 Square Inch

Cylinder Liner/ Engine Block/ Crack Repair of MAN Main Engine/ Metal Lock and Metal Stitching Trade Information

- Minimum Order Quantity

- 1 Square Inch

- Supply Ability

- 1 Square Inch Per Day

- Delivery Time

- 2-3 Days

About Cylinder Liner/ Engine Block/ Crack Repair of MAN Main Engine/ Metal Lock and Metal Stitching

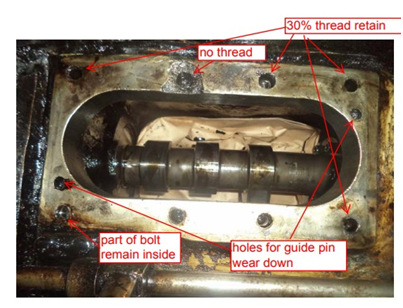

Repair undertaken by RA Power Solutions

The liners were assembled in the presence of our technicians and the engine was put on operation after the leak test. The performance of the engine after crack repair of cylinder liners and engine block is observed satisfactory.

Efficient, Precise Onsite Repairs Worldwide

Our expert team provides Cylinder Liner and Engine Block Crack Repairs onsitewhether you operate marine vessels or power plantsanywhere globally. This service maximizes efficiency, drastically reducing operational downtime compared to traditional welding or component replacement. We ensure every repair is performed with precision, maintaining original engine geometry and delivering reliable, lasting results.

Eco-Friendly Cold Repair Technology

Utilizing the Metal Lock and Metal Stitching cold repair technique, we eliminate harmful emissions and hazardous waste. Theres no heat-affected zone, which preserves material properties and minimizes risks associated with distortion or stress. Our approach is eco-conscious, safe for your operations, and compliant with stringent environmental standards.

FAQs of Cylinder Liner/ Engine Block/ Crack Repair of MAN Main Engine/ Metal Lock and Metal Stitching:

Q: How does the Metal Lock and Metal Stitching repair process work for MAN Main Engine cylinder liners and blocks?

A: This technique involves interlocking metal inserts and special stitching pins into and across the crack, restoring structural integrity without heat. It is a cold repair process that maintains proper alignment, dimension, and mechanical strength in cast iron and cast steel components.Q: What types and sizes of cracks can be repaired using this method?

A: Repairs are effective for fine hairline cracks as well as larger structural breaks in cylinder liners and engine blocks. The method is versatile and suitable for a wide range of crack sizes and severities.Q: When is onsite Metal Lock and Metal Stitching repair preferable to replacement or welding?

A: Onsite repair is ideal when you need to minimize downtime and avoid the risks of thermal distortion from welding. Our service quickly restores damaged parts strength and function, meaning replacement is usually unnecessary.Q: Where can these crack repairs be performed, and who is eligible for service?

A: We provide onsite repair services worldwide, catering to marine vessels, power plants, and industrial sites. Any operator of MAN Main Engines or similar large industrial engines can benefit from these repairs.Q: What post-repair inspection methods are used to ensure quality?

A: After completion, all repaired areas undergo crack detection testingsuch as Magnetic Particle Inspection (MPI) or Dye Penetrant Inspection (DPI)to ensure the restoration meets safety and performance standards.Q: What are the main benefits of using the Metal Lock and Stitching technique on cylinder liners and engine blocks?

A: The process offers rapid turnaround, high precision, full retention of original parts, no heat-affected zone, restored original strength, improved corrosion resistance, minimal post-repair maintenance, and eliminates hazardous emissions.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Metal Stitching Category

Crack Repair Of Aluminium Bronze and Cast Iron component By Metal Lock and Metal Stitching

Price 1600 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Metal Stitching

Price Range 190000.00 - 3500000.00 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Cast Iron Crack Repair

Price Range 160000.00 - 900000.00 INR / Square Inch

Minimum Order Quantity : 1 , , Square Inch

Crack Repair by Metal Locking and Metal Stitching Process

Price Range 260000.00 - 1300000.00 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS