Insitu And Onsite Crankshaft Journal Repair/ Crankshaft Grinding/ RA Power Solutions

Price 1500 INR/ Square Inch

Insitu And Onsite Crankshaft Journal Repair/ Crankshaft Grinding/ RA Power Solutions Trade Information

- Minimum Order Quantity

- 1 Square Inch

- Supply Ability

- 1 Square Inch Per Day

- Delivery Time

- 2-3 Days

- Main Domestic Market

- Haryana

About Insitu And Onsite Crankshaft Journal Repair/ Crankshaft Grinding/ RA Power Solutions

We specialise in grinding and polishing of crankshaft journal insitu and onsite up to 700 mm in terms of diameter. We have experience of more than forty years in executing successfully repair of crankshaft journals onsite without removing the crankshaft from the engine block.

The crankshaft journal repair services are offered all over the world in a short notice and it is possible because all our technicians & supervisors hold valid Indian CDC.

Successful Repair of Crankshaft with damaged Radius fillet due to accident.

It is observed that the leading companies in the world are not able to undertake the grinding of journals in case the radius fillet of the crank pin or main journal of the crankshaft is damaged. Their grinding tool is mounted on the radius fillet and all the references for grinding and polishing are taken from the fillet radius.

In case of damage to the radius fillet it is not possible for them to use their outdated grinding equipment. They always insist for first repair of the radius fillet charging exorbitant and unreasonable amounts. This not only costs very high to the client but also holds the vessel.

Use of Latest designed onsite Crankshaft Journal Grinding Machine by RA Power Solutions:

- Having experience of more than forty years in extending the crankshaft grinding services, we have developed on site crankshaft journal grinding equipment which is of the latest design and technology. The machine works on a bench type crankshaft grinding concept and moves on its own axes. No reference of radius fillet is taken.

- The main equipment body is manufactured out of Titanium alloy and has the inherent property of absorbing the vibrations. Our equipment is designed to work even while sailing and rough weather. There is no requirement of holding the vessel.

Original and experienced on site crankshaft journal repair company

- RA Power Solutions is the original company which developed the compact & light weight onsite crankshaft grinding equipment. We have sold more then 70 Crankshaft grinding and polishing equipment all over the world, training on job our clients technicians.

- The use of our advanced onsite crankshaft grinding machine, the down time of the engine is reduced considerably. In certain cases depending on the diameter of the crankpin & main journal we can put back the engine in operation after crankshaft repair within 12 hrs.

- The equipment is so compact that even in limited space or the crank pin having small bearing width it can be accommodated and grinding can be undertaken.

- We have been regularly executing the repairs in Madagascar, Oman, Qatar, Philippines, Bahrain, Srilanka, Bangladesh, Myanmar, Turkey, Nigeria, Greece, Saudi Arabia, UK, Dubai, Malta, Cyprus, Singapore, Malaysia, Colombia, Indonesia, Hong Kong, Spain, Netherlands, Dubai, Portugal, Estonia, Morocco, Belgium, Vietnam, Canada.

Onsite Crankshaft Grinding with Precision

Our portable technology enables precise grinding directly at the client's location, eliminating the need for dismantling or transportation. RA Power Solutions' proven method delivers in-situ repairs with tolerances up to 0.01 mm, restoring functionality efficiently for critical engine components. The process minimizes downtime and ensures consistent quality, even for extensive repairs on large-diameter crankshafts.

Comprehensive Repair Process and Inspection

Experienced technicians conduct initial assessments, followed by grinding and polishing with high-tech equipment tailored for crankshafts of 35 mm to 700 mm diameter. Each repair includes crack detection, hardness measurement, dimensional checks, and the provision of a detailed inspection report, ensuring work conforms to industry standards and meets ISO 9001:2015 requirements.

Rapid Response and Emergency Service

Our service team provides immediate mobilization, offering 24/7 support for urgent requirements. RA Power Solutions swiftly addresses breakdowns in industrial engines, marine vessels, and generator sets, ensuring continuous productivity and reliability for mission-critical operations.

FAQ's of Insitu And Onsite Crankshaft Journal Repair/ Crankshaft Grinding/ RA Power Solutions:

Q: How is the insitu crankshaft journal repair process carried out onsite?

A: RA Power Solutions deploys portable crankshaft grinding equipment to the client's location, where qualified technicians perform precision grinding, polishing, and necessary checks without removing the crankshaft from the engine block. This eliminates logistic delays and ensures immediate restoration of engine performance.Q: What types of engines are suitable for onsite crankshaft grinding services?

A: Our services cater to 4-stroke and 2-stroke reciprocating engines used in industrial applications, marine vessels, diesel generators, and other locations where large crankshafts (35 mm to 700 mm diameter, stroke up to 600 mm) are operational.Q: When can emergency crankshaft repair services be accessed?

A: We offer 24/7 emergency support upon request, providing swift mobilization of technicians and equipment to address mechanical failures and minimize operational downtime for our clients in critical industries.Q: Where is the crankshaft repair performed, and what is required from the client?

A: Repairs are performed onsite at the client's premises. The client is only required to provide adequate access to the crankshaft within their engine or machinery, allowing our technicians to set up portable grinding machines for efficient service delivery.Q: What post-repair inspections and documentation are provided?

A: Upon completion, every repair undergoes crack detection, hardness testing, and dimensional checks. Clients receive a comprehensive inspection report detailing the repair process, measurements achieved, and quality assurance steps undertaken.Q: How does onsite crankshaft grinding benefit engine owners?

A: Onsite grinding reduces equipment downtime, eliminates the need for transportation, and ensures the crankshaft's operational standards are restored quickly. Surface finish quality meets Ra less than 0.20 micron, leading to enhanced engine efficiency and reliability.Q: What safety and quality standards does RA Power Solutions comply with?

A: All services are performed in accordance with ISO 9001:2015 certified procedures, using experienced technicians and calibrated equipment to guarantee operational safety and repair integrity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Crankshaft Repair Category

Onsite Crankshaft Grinding Machine

Price 300000 INR / Square Inch

Minimum Order Quantity : 1 , , Square Inch

MAN 9 ASL 25/30 Crankshaft Repair/in situ Crankshaft Grinding RA Power Solutions

Price 1500 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

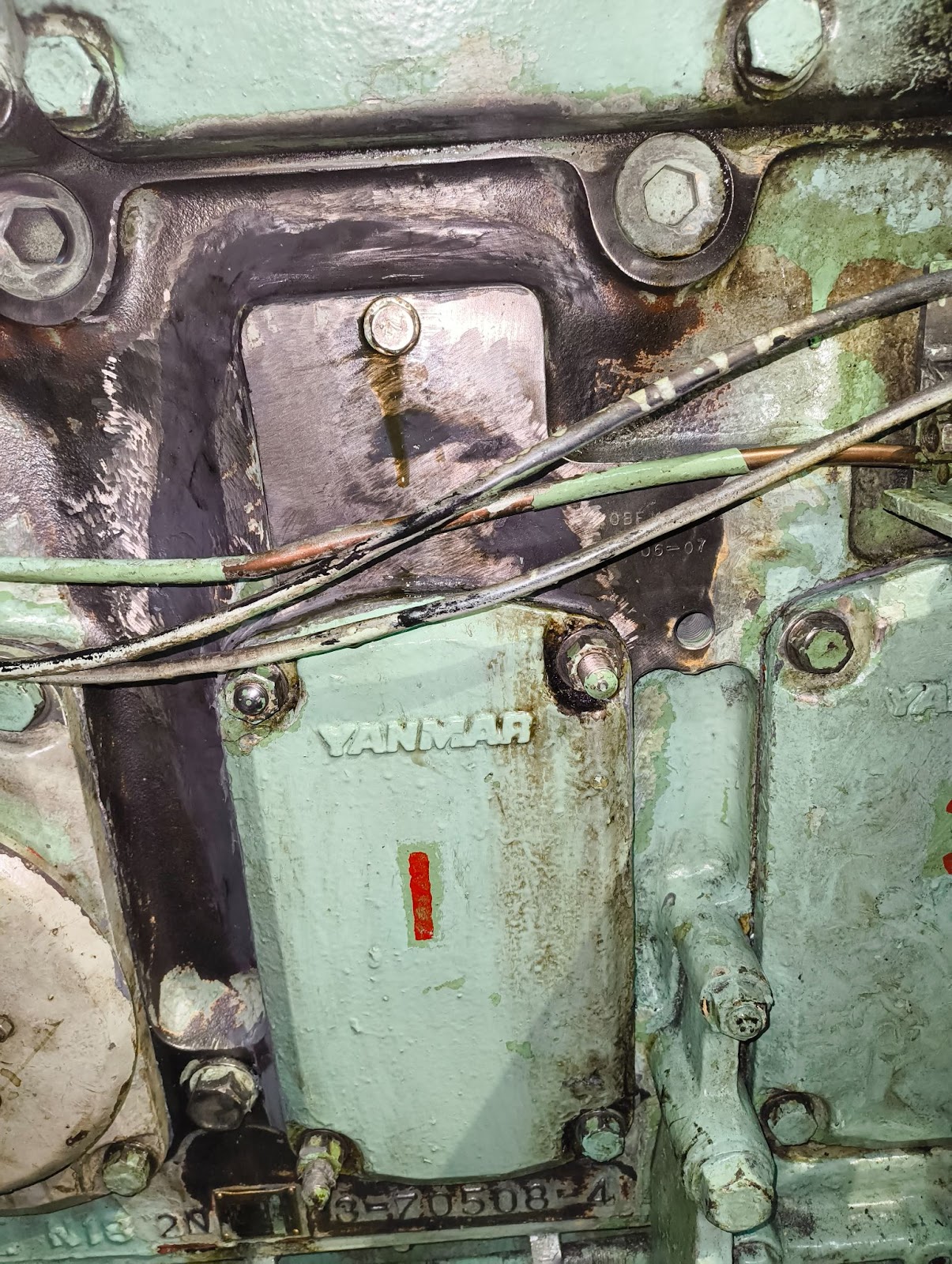

YANMAR 6N18L-SV Auxiliary Engine Crankshaft

Price 1000.0 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS