MAN B&W 6L23/30H Crankshaft Repair | While Sailing of Vessel | RA Power Solutions With 45 Years Experience

Price 2.0 INR/ Number

MAN B&W 6L23/30H Crankshaft Repair | While Sailing of Vessel | RA Power Solutions With 45 Years Experience Trade Information

- Minimum Order Quantity

- 1 Number

- Delivery Time

- 1 Hours

About MAN B&W 6L23/30H Crankshaft Repair | While Sailing of Vessel | RA Power Solutions With 45 Years Experience

The MAN B&W 6L23/30H engine belonging to our client, a leading shipping company based in Dubai, met with an accident near Singapore. The details of the crankshaft damage and engine specifications are as follows:

| S. No. | Crankpin and Main Journal Details | |

| 1 | Engine Make | MAN B & W |

| 2 | Engine Model | 6L23/30H |

| 3 | Crankpin Diameter Standard | 185.00 MM |

| 4 | Crankpin Bearing Width | 70.00 MM |

| 5 | Grinding of Crankpin Number | #01, #02, #03, #04, #05, #06 |

| 6 | Place of Execution of Grinding of Crankpin | During Sailing From Singapore Anchorage to Taiwan |

| 7 | Name of Shipping Company | A Reputed Shipping Company Based In Dubai, UAE |

| Damaged Crankpin of MAN B&W 6L23/30H | MAN B&W 6L23/30H damaged crankpin |

The vessel was scheduled to sail from Singapore Anchorage to Taiwan. Our technicians, along with the onsite crankshaft grinding machine, boarded the vessel at Singapore Anchorage and sailed to the Port of Taiwan. During the sailing, an inspection of the MAN B&W 6L23/30H crankshaft was conducted, and the necessary repairs were successfully executed.

|

|

|

| Crankpin Before Grinding | MAN B&W 6L23/30H Crankpin before Grinding and Polishing |

Step Taken to Onsite Repair Of MAN B&W 6L23/30H Crankshaft

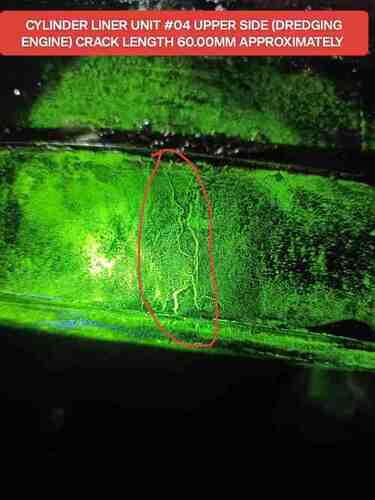

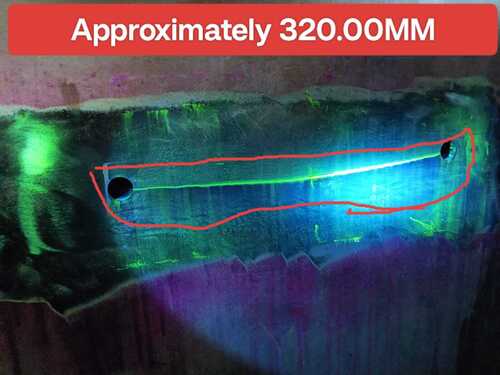

i) A pre-inspection of all the crankpins was conducted. Crack detection using MPI and hardness testing were also carried out. The dimensional report is as follows:

|

SIZE OF CR PINS BEFORE REPAIR SIZE OF CR PINS BEFORE REPAIR |

|||||||||

| A | Aa | C | Cc | B | Bb | Min | Max | Ovality | |

| CR-1 | 184.80 | 184.79 | 184.83 | 184.82 | 184.79 | 184.78 | 184.78 | 185.00 | 0.22 MM |

| CR-2 | 184.70 | 184.84 | 183.82 | 184.40 | 184.81 | 184.50 | 183.82 | 185.00 | 1.18 MM |

| CR-3 | 184.81 | 184.82 | 184.88 | 184.84 | 184.79 | 184.78 | 184.78 | 185.00 | 0.22 MM |

| CR-4 | 184.81 | 184.77 | 184.81 | 184.83 | 184.80 | 184.77 | 184.77 | 185.00 | 0.23 MM |

| CR-5 | 184.87 | 184.82 | 184.91 | 184.84 | 184.88 | 184.89 | 184.82 | 185.00 | 0.18 MM |

| CR-6 | 184.78 | 184.77 | 184.86 | 184.80 | 184.74 | 184.76 | 184.74 | 185.00 | 0.26 MM |

|

|

|

| MAN B&W crankpin crack detection test | MAN B&W 6L/23 30H Crankshaft Inspection |

ii) Considering the excessive ovality in Crankpin Number #02, it was undersized by 2.00 MM, and the remaining crankpins were undersized by 0.5 MM. The Final Report is pasted below:

| SIZE OF CR PINS AFTER REPAIR | |||||||||

| A | Aa | C | Cc | B | Bb | Min | Max | Ovality | |

| CR-1 | 184.48 | 184.49 | 184.50 | 184.48 | 184.49 | 184.48 | 184.48 | 184.50 | 0.02 MM |

| CR-2 | 182.98 | 182.99 | 182.98 | 182.99 | 183.00 | 182.98 | 182.98 | 183.00 | 0.02 MM |

| CR-3 | 184.48 | 184.49 | 184.48 | 184.50 | 184.49 | 184.48 | 184.48 | 184.50 | 0.02 MM |

| CR-4 | 184.48 | 184.49 | 184.50 | 184.48 | 184.49 | 184.48 | 184.48 | 184.50 | 0.02 MM |

| CR-5 | 184.48 | 184.49 | 184.50 | 184.49 | 184.48 | 184.49 | 184.48 | 184.50 | 0.02 MM |

| CR-6 | 184.49 | 184.48 | 184.49 | 184.50 | 184.48 | 184.49 | 184.48 | 184.50 | 0.02 MM |

|

|

|

| In situ crankshaft grinding under process | MAN B&W Crankshaft During Repairs |

RA Power Solutions Maintains A Large Stock of Undersized Crankpin Bearings of MAN B&W 6L23/30H Engine

We have crankpin undersized bearings available in our stock up to 5.00 mm in the following two configurations.

a) Key Position *7.7 10.7 *

b) Key Position *12.5 15.5 *

In this case, RA Power Solutions supplied undersized bearings of 0.50 mm and 2.00 mm with a key position of 12.5 15.5 onboard the vessel, and the engine was put back into operation immediately.

|

|

|

| MAN B&W 6L23 30H Crankpin after Grinding | After Grinding and Polishing of MAN B&W 6L23 30H |

We have a team of trained technicians available 24/7 and can be deputed on short notice. Some of our technicians also have valid US visas and can fly to South America, Caribbean countries, etc.

R A Power Solutions delivers expert onsite crankshaft grinding and repair services for major engine brands, including Caterpillar, Wartsila, Cummins, Yanmar, Daihatsu, MAN, and MAK. Our certified technicians operate across the Middle East (UAE, Saudi Arabia, Qatar, Bahrain, Kuwait, Oman, Iran, and Iraq) and throughout the Caribbean region, including Trinidad and Tobago, Jamaica, Barbados, and Central America. With advanced portable grinding equipment and 24/7 emergency response, we eliminate costly downtime by performing precision repairs onsite without engine removal, ensuring your operations stay running while meeting OEM specifications.

For more information regarding crankshaft grinding services, please contact us at rajshahani@rapowersolutions.com or info@rapowersolutions.com or call us at +91 9582647131 or +91 9810012383.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Crankshaft Repair Category

Crack Repair of A Press Frame-3500 Ton

Price 775.0 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Bergen Rolls Royce Crankshaft Repair / Rolls Royce Engine Crankshaft Grinding / RA Power Solutions

Price 1500 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Onsite Crankshaft Repair by Ra Power

Price 13000 INR / Number

Minimum Order Quantity : 1 Square Inch

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS