Onsite Crankshaft Grinding Machine

Price 300000 INR/ Square Inch

Onsite Crankshaft Grinding Machine Specification

- Maximum Grinding Diameter

- 700 mm

- Control

- Manual/Automatic Options

- Usage

- Crankshaft Repair & Grinding Onsite

- Minimum Grinding Diameter

- 30 mm

- Accessories Included

- Tool Kit, Measuring Instruments

- Spindle Speed

- Variable (as per requirement)

- Surface Finish

- Ra 0.2 0.4 m

- Grinding Accuracy

- Up to 0.02 mm

- Material

- Alloy Steel/Custom as Required

- Portable Type

- Onsite (Portable)

Onsite Crankshaft Grinding Machine Trade Information

- Minimum Order Quantity

- 1 , , Square Inch

- Supply Ability

- 1 , , Square Inch Per Day

- Delivery Time

- 2-3 Days

About Onsite Crankshaft Grinding Machine

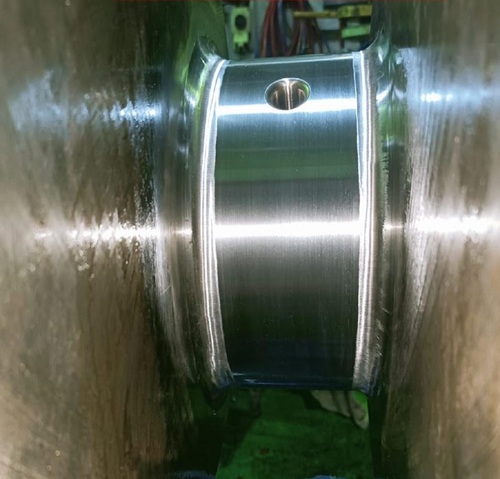

Crankshaft Repair Of Man 6l 16 24 By Compact And Portable Crankshaft Grinding Machine

RA Power Solutions is the only company which has the equipment available to work on the crankpin bearing width or main journal bearing width which is as low as 40 mm.

This technologically advanced latest generation of crankshaft grinding equipment is only available with us and have successfully repaired thousands of crankshaft all over the world in countries like Greece, Moldova, Belarus, Australia, Austria, Belgium, Brazil, Cambodia, Colombia, Denmark, Ethiopia, Ghana, Haiti etc.

Contact us for more information.

Precision Grinding Onsite

Experience hassle-free crankshaft repair at your location with this portable grinding machine. Engineered for versatility, it allows both manual and automatic operation, facilitating accurate crankshaft restoration with minimal downtime. The systems high grinding precision and premium surface finishing ensure reliability in diverse industrial applications.

Robust Construction and Accessories

Crafted from alloy steel or custom materials, the machine endures demanding onsite repair work. Included accessoriesranging from a comprehensive tool kit to precise measuring instrumentssimplify setup and ensure consistent, high-accuracy results throughout the grinding process.

FAQs of Onsite Crankshaft Grinding Machine:

Q: How does the onsite crankshaft grinding machine operate during repairs?

A: The machine is positioned directly on the crankshaft, enabling in-situ grinding without removing the shaft from the engine block. It can be operated manually or with automatic controls, allowing technicians to accommodate specific requirements during repair operations.Q: What is the process for grinding crankshafts onsite using this machine?

A: Grinding begins by setting up the machine around the crankshaft, selecting the appropriate spindle speed and controls. Measuring instruments are used throughout to monitor accuracy, ensuring the final result meets the desired tolerance and surface finish standards.Q: When should you use the onsite crankshaft grinding machine?

A: This machine is recommended when crankshafts require grinding, repair, or restoration, especially in large diesel, marine, or industrial engines where disassembly is time-consuming or impractical.Q: Where can the onsite crankshaft grinding machine be used?

A: It is designed for onsite application in various settings such as shipyards, power plants, manufacturing facilities, and heavy engineering workshops across India and abroad.Q: What are the benefits of using this portable machine for crankshaft repair?

A: The key advantages include eliminating the need for crankshaft removal, reducing engine downtime, ensuring high-precision restoration, and delivering a superior surface finish. Its portability makes it easy and cost-effective for use on location.Q: What usage options are available with the machines controls?

A: The grinding machine offers both manual and automatic operational modes, allowing users to select the best approach for each repair scenario to optimize efficiency and grinding accuracy.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Crankshaft Repair Category

HIMSEN HYUNDAI 6H 17/28 Crankshaft

Price 1000.0 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Repair of Wartsila 4L20 Crankshaft

Price 16000 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Crankshaft Repair of Yanmar Engine 6N165

Price 16000 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Wartsila Engine 4L20 Crankshaft Repair

Price 1000.0 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS