Repair of Sulzer Engine 6ZAL 40S Crankshaft

Price 1600 INR/ Square Inch

MOQ : 1 Square Inch

Repair of Sulzer Engine 6ZAL 40S Crankshaft Trade Information

- Minimum Order Quantity

- 1 Square Inch

- Supply Ability

- 1 Square Inch Per Day

- Delivery Time

- 2-3 Days

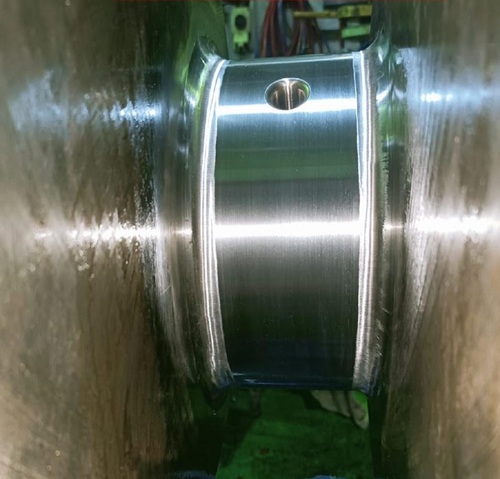

About Repair of Sulzer Engine 6ZAL 40S Crankshaft

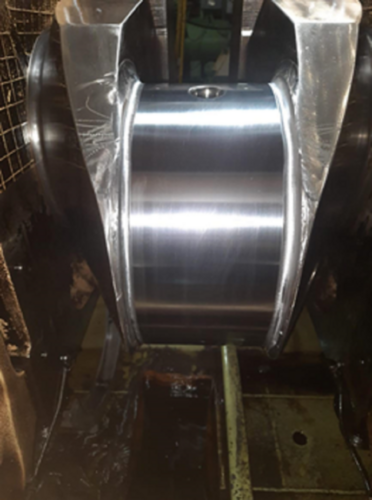

RA Power Solutions is acknowledged all over the world as a leader for grinding of crankshafts onsite without removing them from the engine block.

The advantage of RA Power Solutions:

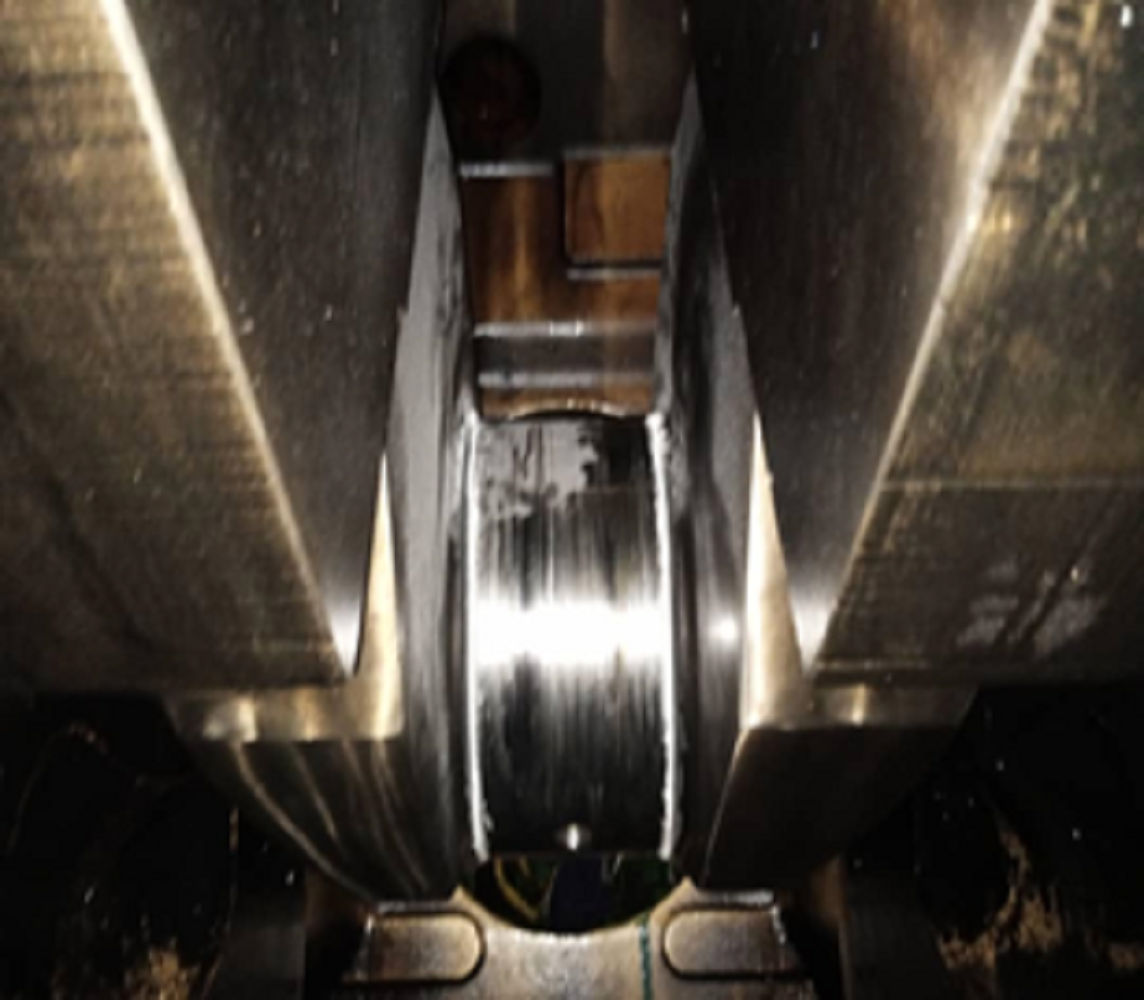

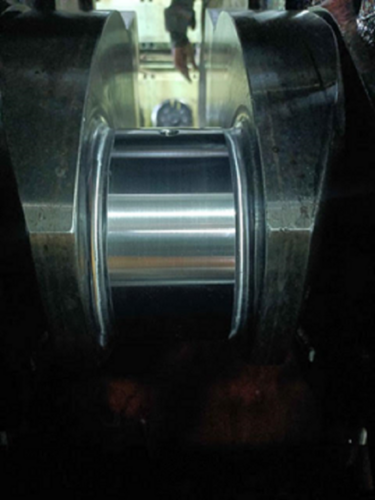

- Use of a specially designed compact onsite grinding machine capable of undertaking crankshaft grinding without involving the dismantling of the shaft from the entablature.

- Crankshaft grinding machines are manufactured in-house and can be designed & modified as per the site requirements. This is of great advantage to our clients from shipping companies, power plants, etc.

- In-house trained engineers and mechanics skilled in the art of in situ crankshaft grinding.

- It is possible to repair the crankshaft even while sailing the vessel, the ready availability of tools, technical data, and technicians.

- All technicians have seaman books and some of them have US visas. They can sail from one port to another.

For more details on the Repair of the engine or crankshaft grinding on the vessel please email us at info@rapowersolutions.com Call at +91-9582647131.

Comprehensive Repair Solutions

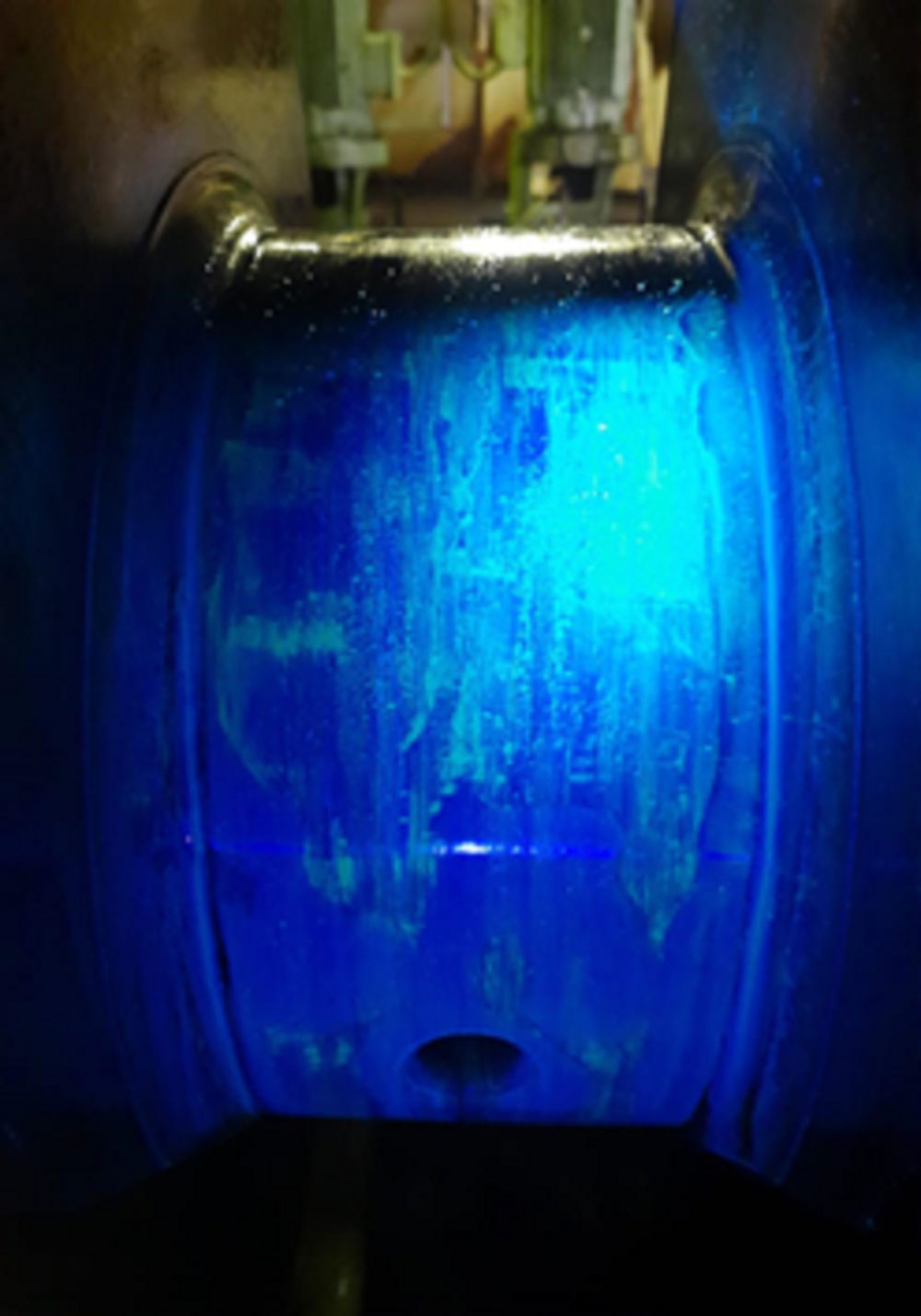

Our crankshaft repair service for the Sulzer 6ZAL 40S covers grinding, journal rebuilding, polishing, and crack detection, using specialized equipment. Surface finish, hardening, and balancing are performed to meet stringent standards. Each repair aims to maximize crankshaft life and keep your marine or industrial engine performing at its best.

Quality and Compliance at Every Step

All repair services adhere to ISO 9001:2015, IACS, and original manufacturer standards. Every crankshaft undergoes dimensional checks, ultrasonic testing, and magnetic particle examination. Alignment verification is standard procedure, and all replacement parts are OEM-approved or equivalent, ensuring dependability.

Flexible Service and Reliable Support

We provide repair services on-site or at our specialized workshops, based in India, depending on your operational requirements and project scale. Logistics and handling support are available to ensure safe transportation. Clients receive a comprehensive damage assessment and repair report for complete transparency.

FAQ's of Repair of Sulzer Engine 6ZAL 40S Crankshaft:

Q: How is the Sulzer 6ZAL 40S crankshaft repair process carried out?

A: The repair process includes damage assessment, crack detection, journal rebuilding, precision grinding to OEM standards, polishing to Ra 0.2 - 0.4 micron, and optional heat treatment for stress relief. All repairs are followed by dynamic balancing, alignment checks, and thorough inspection for quality assurance.Q: What inspection methods are used during repair?

A: We utilize ultrasonic testing, magnetic particle examination, and detailed dimensional checks to identify cracks, wear, or structural issues. These methods ensure the repaired crankshaft meets all safety and manufacturer requirements.Q: When and where can this repair service be performed?

A: Services can be conducted on-site at your facility or at our specialized workshops in India, based on your needs and equipment condition. The scheduling and turnaround depend on damage severity and the scope of repair required.Q: What are the benefits of using OEM-approved or equivalent replacement parts?

A: OEM-approved or equivalent replacement parts ensure long-term compatibility, durability, and performance. This minimizes the risk of premature failure and aligns with manufacturer guidelines, preserving engine reliability.Q: Who provides logistics support for crankshaft transportation?

A: We offer logistics support including safe transportation and handling of crankshafts to and from your location, ensuring every component is managed securely throughout the repair cycle.Q: How do customers benefit from the provided damage assessment report?

A: The detailed damage assessment report outlines detected issues, performed repairs, and final inspection results. This ensures transparency, supports maintenance records, and helps in future engine management planning.Q: What makes this crankshaft repair service compliant with industry standards?

A: The entire repair process aligns with ISO 9001:2015, IACS rules, and Sulzer manufacturer standards. All procedures, inspections, and documentation are structured to deliver quality repairs that meet global industry benchmarks.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Crankshaft Repair Category

Crankshaft Repair Engine MAN 5L 16/24

Price 16000 USD ($) / Square Inch

Minimum Order Quantity : 1 Square Inch

Naval STORK Werkspoor S.A Engine Repair in Haiti

Price 1 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Wartsila Vasa Type: 6R32 Engine Crankshaft Repair | Dominican Republic

Price 1500 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Repair of Wartsila 4L20 Crankshaft

Price 16000 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS