Repair on Vessel of Auxiliary Engine Crankshaft

Price 1600 USD ($)/ Number

Repair on Vessel of Auxiliary Engine Crankshaft Specification

- Finish Type

- Precision Ground

- Thread size

- Standard metric (varies per engine)

- Usage

- Vessel auxiliary engine maintenance and repair

- Thickness

- Optimized for strength and reliability

- Material Grade

- EN24/EN19 or Equivalent

- Cooling System

- Water-cooled

- Power Output

- Up to 1200 kW

- Other Features

- On-site machining, Crack detection and balancing

- Inner Diameter

- As per design

- Outlet Diameter

- As per design

- Engine Type

- Diesel

- Load Capacity

- Up to 2500 Nm torque

- Mount Type

- Flanged / Press fit

- Fuel Type

- Marine Diesel

- Product Type

- Crankshaft Repair

- Parts Name

- Auxiliary Engine Crankshaft

- Material

- Forged Steel

- Application

- Marine Auxiliary Engine

- OE Number

- AUX-CRANK-001

- Size

- Standard (customizable based on engine model)

- Dimensions

- Custom-fit as per engine requirements

- Weight

- Depends on crankshaft size

- Power

- Suitable for up to 1200 kW

- Stroke

- Variable as per Engine Specification

- Head

- Single Cylinder/Multiple Cylinder Depending on Engine

Repair on Vessel of Auxiliary Engine Crankshaft Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 1 Number Per Day

- Delivery Time

- 2-3 Days

About Repair on Vessel of Auxiliary Engine Crankshaft

We are giving below the details of a few engines and their model crankshaft which we have been repairing regularly all over the world successfully.| Sr. No. | Engine Make | Engine Model | Diameter |

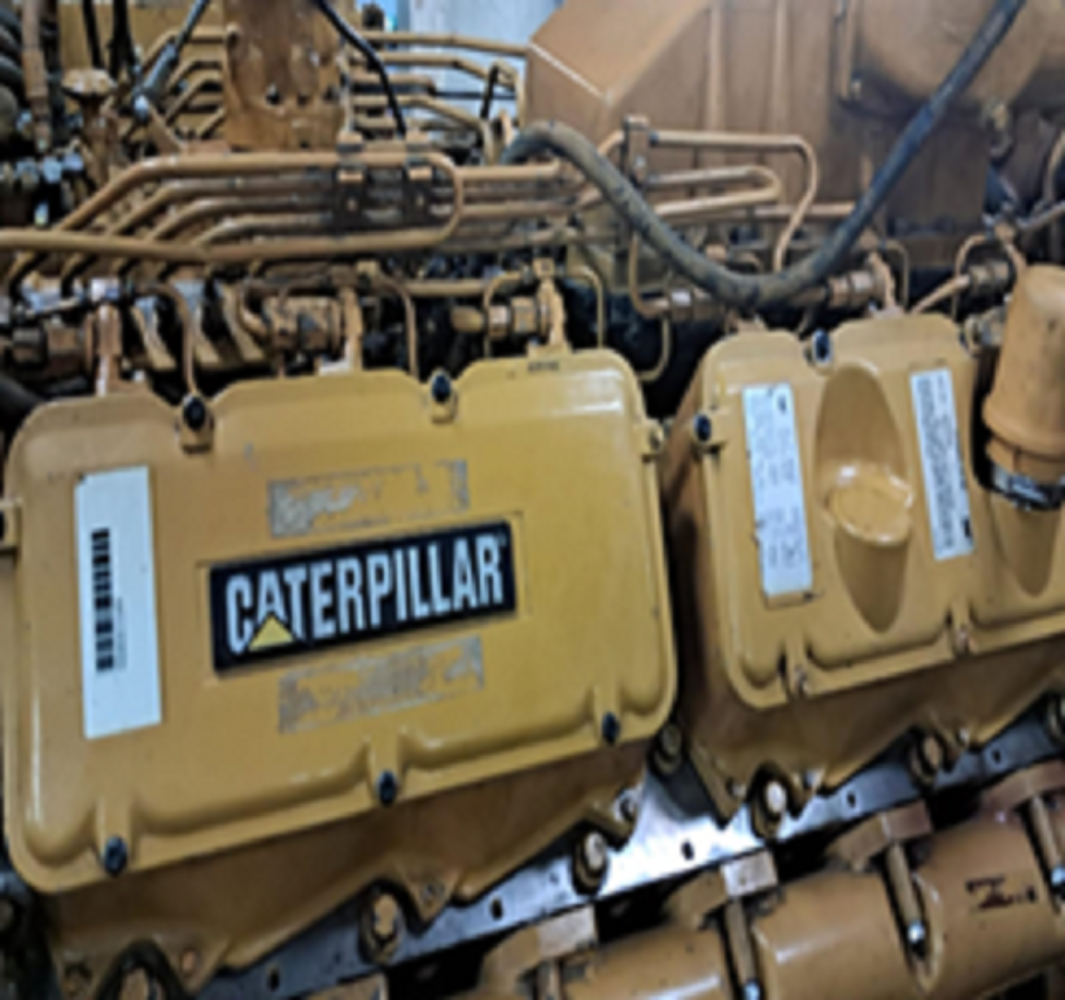

| 1 | Caterpillar | 3500B, 3500C & 3416B | 135.00 mm |

| 2 | Caterpillar | D379, D398 & D399 | 127.00 mm |

| 3 | Allen | 8BCS 12.8 | 165.00 mm |

| 4 | Daihatsu | 14A | 95.00 mm |

| 5 | Daihatsu | Pk-14A | 90.00 mm |

| 6 | Daihatsu | PK-16 | 110.00 mm |

| 7 | Daihatsu | PS-18D | 125.00 mm |

| 8 | Daihatsu | PS-20 | 135.00 mm |

| 9 | Daihatsu | VS-20 | 135.00 mm |

| 10 | Daihatsu | PS-22 | 155.00 mm |

| 11 | Daihatsu | DS-18 | 145.00 mm |

| 12 | Daihatsu | DS -18A | 145.00 mm |

| 13 | Daihatsu | DS-19A | 145.00 mm |

| 14 | Daihatsu | DL-19 | 145.00 mm |

| 15 | Daihatsu | PS-22 | 155.00 mm |

| 16 | Daihatsu | 5DC-17 | 145.00 mm |

| 17 | Daihatsu | 5DK-20 | 170.00 mm |

| 18 | Daihatsu | 6DL-16 | 120.00 mm |

| 19 | Man | 16/24 | 130.00 mm |

| 20 | Man | 23/30, H | 185.00 mm |

| 21 | Man | MTBH 625 | 170.00 mm |

| 22 | Man | 20MTB-30 | 135.00 mm |

| 23 | MAK | M331 AK | 180.00 mm |

| 24 | MAK | 36 | 105.00 mm |

| 25 | MAK | 423 | 126.00 mm |

| 26 | MAK | 426 | 124.00 mm |

| 27 | MAK | M20 | 152.00 mm |

| 28 | Wartsila | L20 | 180.00 mm |

| 29 | Wartsila | R22H | 180.00 mm |

| 30 | Wartsila | 824TS | 175.00 mm |

| 31 | Yanmar | 6A L | 125.00 mm |

| 32 | Yanmar | 6M L | 138.00 mm |

| 33 | Yanmar | 6N18 | 145.00 mm |

| 34 | Yanmar | M220 | 170.00 mm |

| 35 | Yanmar | S185 L | 140.00 mm |

| 36 | Yanmar | M200AL-DT | 152.00 mm |

We have successfully repaired thousands of crankshafts with small crankpin diameter and bearing lengths. We can share the details including pre and final inspection reports duly signed and stamped by the chief engineer of a vessel.

For more details of the Repair of engine and supply of bearings please email us on info@rapowersolutions.com Call at +91-9582647131

Comprehensive Crankshaft Restoration

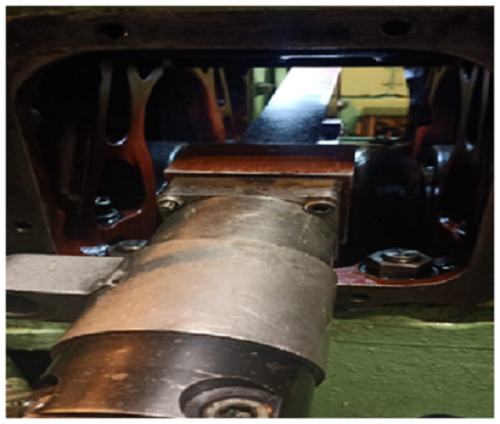

Our repair process restores forged steel auxiliary engine crankshafts to optimal performance, including precision CNC grinding, metal build-up, and fine surface finishing. All units are crack tested, balanced, and tailored for EN24, EN19, or equivalent material grades. Repairs can be performed both on-site and dockside, minimizing vessel downtime and ensuring rapid reintegration.

Stringent Quality and Inspection Standards

Every crankshaft repair is rigorously inspected using ultrasonic and magnetic particle testing. Dimensional accuracy is held within 0.01 mm tolerance, and surface hardness reaches 55-60 HRC post repair. Customers receive both repair quality certificates and detailed dimensional reports, supporting compliance and continued reliability at sea.

Marine Engine Compatibility

Our services are tailored for a broad spectrum of vessels and engines, including MAN B&W, Yanmar, Wartsila, Cummins, and others. Whether it's single or multi-throw, single or multi-cylinder designs, we ensure the crankshaft is restored for marine auxiliary engines producing up to 1200 kW, supporting various mounting, stroke, and custom-fit dimensions.

FAQ's of Repair on Vessel of Auxiliary Engine Crankshaft:

Q: How is the crankshaft surface hardness restored to 55-60 HRC after repair?

A: The crankshaft undergoes CNC grinding followed by metal spray or metal build-up, then precision finishing. This process effectively restores surface hardness to the required 55-60 HRC, ensuring high wear resistance and durability under marine operating conditions.Q: What inspection methods are used to ensure the quality of repaired crankshafts?

A: After repair, every crankshaft is subject to ultrasonic and magnetic particle inspection. These non-destructive tests detect any subsurface or surface cracks, ensuring the structural integrity and serviceability of the component before it is certified for use.Q: When can I expect my crankshaft repair to be completed, especially for emergencies?

A: For shipboard emergencies, our turnaround time is typically between 48 and 72 hours, depending on repair complexity and location. This fast service ensures minimal operational delay for marine vessels.Q: Where are the crankshaft repairs performed, and is on-site service available?

A: Repairs can be carried out on-site (in-situ) or at a dockside location using advanced portable equipment. Our engineers are equipped to deliver high-quality repairs directly aboard vessels wherever required.Q: What is the process for repairing a marine auxiliary engine crankshaft?

A: The repair process includes CNC grinding, metal build-up if necessary, crack detection, and dynamic balancing. After confirming dimensional accuracy and surface properties, the crankshaft undergoes final inspection before packaging and shipment.Q: How does this repair service benefit vessel operators?

A: Operators benefit from enhanced crankshaft longevity, optimized corrosion resistance, and reduced downtime thanks to rapid turnaround. Additionally, comprehensive inspections and certified reports contribute to safer and more reliable vessel operations.Q: What engine models and brands are supported by this repair service?

A: Our crankshaft repair solutions are compatible with a wide range of marine engines, including MAN B&W, Yanmar, Wartsila, Cummins, and other leading brands. Customization is available for varying designs and specifications to ensure a perfect fit and function.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in engine spare parts Category

MAN Diesel Generator Model no. 9L28/32

Price 1500 USD ($) / Number

Minimum Order Quantity : 1 Number

Application : Marine, Industrial, Power Plants

Head : 9

Parts Name : Other, Diesel Generator

Power : 3000 kW

Crankshaft Grinding Machine Portable - Engineering Revolution

Price 1500 USD ($) / Number

Minimum Order Quantity : 1 Number

Application : Crankshaft Repair and Grinding

Head : Precision Adjustable Grinder Head

Parts Name : Other, Crankshaft Grinder

Power : Electric 220V, 50Hz

Yanmar Engine 6N18AL-DV, S185L-ST, 6M 220L-SN, 6N21L-SN, 6N330-EN, M200AL-DT, 8N280L-EV, 8EY33LW Crankshaft repair | Crankshaft grinding

Price 1500 USD ($) / Number

Minimum Order Quantity : 1 Number

Application : Yanmar Marine Diesel Engines

Head : As per engine specification

Parts Name : Other, Crankshaft

Power : As per engine rating

Man B&W 5T23LH, 6L23/30, 9L 27/38, 7L 32/40, 7L 16/24, 9L28/32, 9L25/30, 6L 52/55B Crankshaft grinding onsite

Price 1500 USD ($) / Number

Minimum Order Quantity : 1 Number

Application : Marine Engines, Power Plants

Head : N/A (Not applicable for crankshaft)

Parts Name : Other, Crankshaft

Power : Engine dependent (up to 7600 kW)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS