Crack Repair Of Aluminium Bronze and Cast Iron component By Metal Lock and Metal Stitching

Price 1600 INR/ Square Inch

MOQ : 1 Square Inch

Crack Repair Of Aluminium Bronze and Cast Iron component By Metal Lock and Metal Stitching Specification

- Portability

- Method suitable for remote and hard-to-reach locations

- Corrosion Resistance

- Excellent

- Tool Requirement

- Specialized Metal Lock and Stitching tools required

- Repair Location

- On-site or Workshop

- Repair Type

- Cold, mechanical process (No welding or heating required)

- Estimated Repair Time

- 2-8 hours depending on size and extent of crack

- Surface Preparation

- Cleaning and degreasing of component surface prior to repair

- Component Material Compatibility

- Aluminium Bronze, Cast Iron

- Repair Method

- Metal Lock and Metal Stitching

- Environmental Friendliness

- No hazardous fumes or emissions generated

- Crack Width Capacity

- Up to 20 mm

- Thermal Expansion Compatibility

- Compatible with parent metal

- Downtime

- Minimal

- Suitability

- Ideal for marine, industrial, and heavy machinery components

- Application

- Repair of cracks in Aluminium Bronze and Cast Iron components

- Crack Monitoring

- Visual inspection post-repair possible

- Crack Length Capacity

- Unlimited

- Insert Material

- High tensile alloy steel or specialist locking pins

- Structural Integrity

- Restores original strength

- Post-Repair Machinability

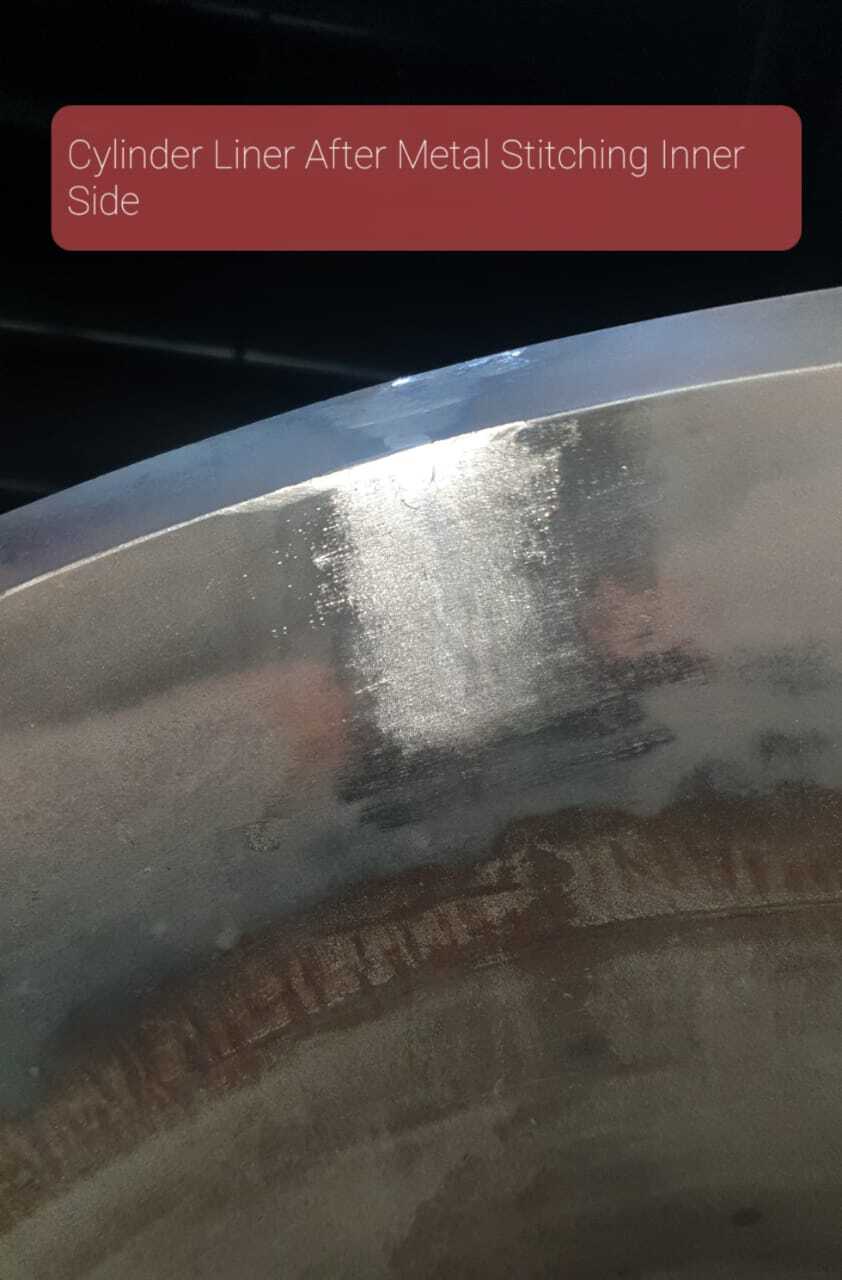

- Machinable to original surface finish

Crack Repair Of Aluminium Bronze and Cast Iron component By Metal Lock and Metal Stitching Trade Information

- Minimum Order Quantity

- 1 Square Inch

- Supply Ability

- 1 Square Inch Per Day

- Delivery Time

- 2-3 Days

About Crack Repair Of Aluminium Bronze and Cast Iron component By Metal Lock and Metal Stitching

RA Power Solutionsis one of the oldest company based in New Delhi, India, undertaking crack repairs of damaged heavy components, manufactured out of cast iron, bronze, aluminium and cast steel. by cold process of metal lock and metal stitching.Metal stitching and metal locking is a simple but proven process of repairing cracks in heavy components without following the wielding method which generates excessive heat.

RA Power Solutions has experienced technicians and a process available by which the damaged portion of the component is completely cut off. The new casting is made of cast iron, cast steel or aluminium as per the original damaged component is manufactured and taken to the site. The new casting is properly assembled and is metal stitched by our experienced technicians using the best quality of metal keys and locks.

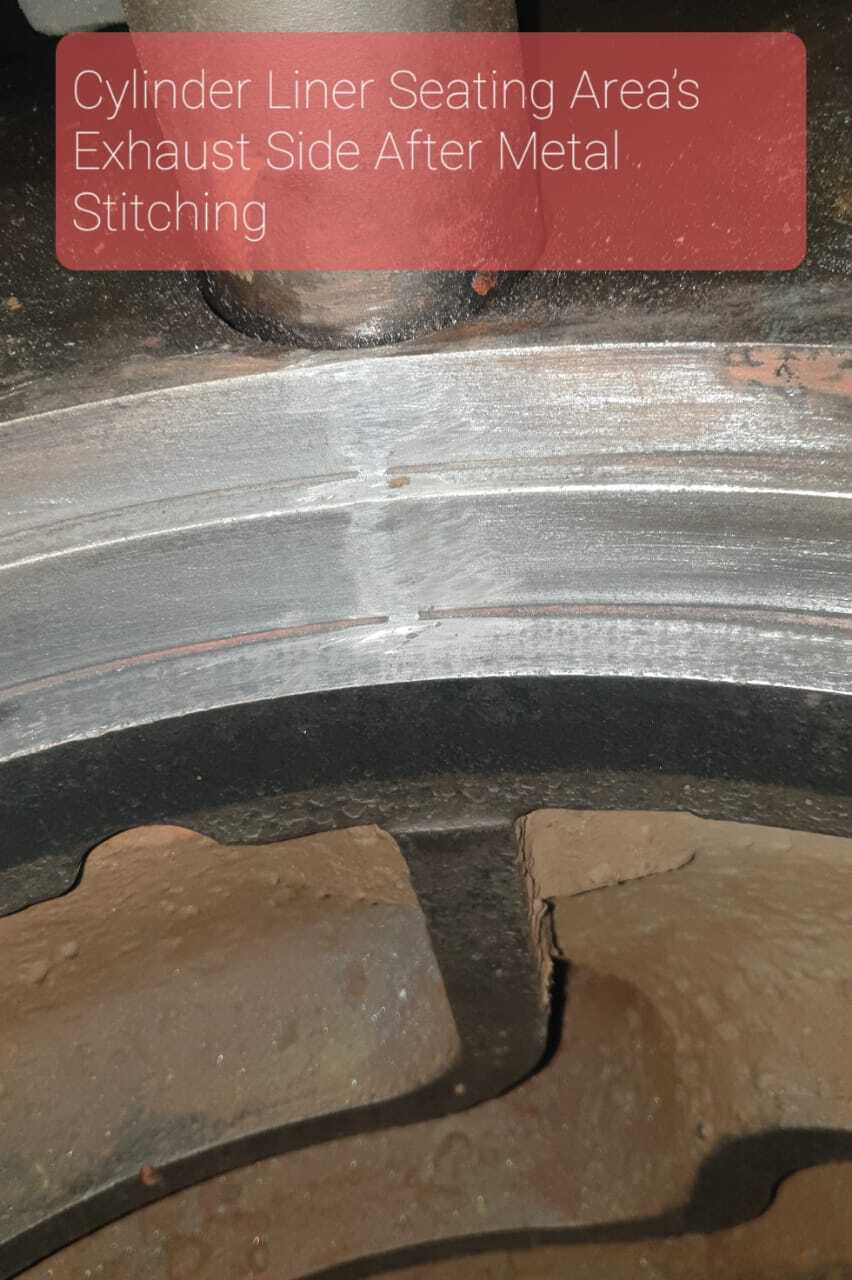

The photograph shown in this blog are of MAN main engine model SMIT MAN R666W (Main Engine Port Side) which met with an serious accident. In this case, we have successfully repaired the engine block, cylinder liner and piston having multiple cracks, length measuring from 75mm to 190 mm.

Precision Surface Preparation

Each component undergoes thorough cleaning and degreasing before repair, ensuring optimal bond strength and longevity of the restoration. This step eliminates contaminants that could compromise the effectiveness of Metal Lock and Stitching, giving the repaired area maximum durability.

High Performance Insert Materials

The use of high-tensile alloy steel and dedicated locking pins ensures robust reinforcement across cracked sections. These inserts are designed to be corrosion-resistant and fully compatible with the expansion properties of Aluminium Bronze and Cast Iron, preserving the structural and operational integrity of the component.

FAQ's of Crack Repair Of Aluminium Bronze and Cast Iron component By Metal Lock and Metal Stitching:

Q: How are cracks in Aluminium Bronze and Cast Iron components repaired using Metal Lock and Metal Stitching?

A: Cracks are repaired by first cleaning and degreasing the surface, followed by inserting high-tensile alloy steel or specialist locking pins within the crack. Metal Lock and Stitching tools mechanically secure the repair, restoring strength without heating or welding.Q: What benefits does this crack repair method offer over traditional welding?

A: This method eliminates hazardous fumes and excessive heat, preserves original metallurgical properties, offers excellent corrosion resistance, and restores the component's original strength with minimal downtime. It is also environmentally friendly and suitable for remote locations.Q: When is visual inspection for crack monitoring performed after the repair?

A: Visual inspection is recommended immediately after completing the repair and periodically during service, ensuring that the restoration remains intact and functionally reliable over time.Q: Where can this repair method be carried out?

A: Crack repair using Metal Lock and Stitching can be performed both on-site and in workshops, making it ideal for marine vessels, industrial plants, and heavy machinery located in remote or challenging environments.Q: What is the process for preparing a component before repair?

A: Prior to repair, the affected component undergoes meticulous surface cleaning and degreasing to remove any contaminants, facilitating strong adhesion and optimal performance of the locking system.Q: Is the repaired surface machinable to its original finish?

A: Yes, after the repair process, the surface can be machined to restore its original finish, ensuring the component's functional and aesthetic qualities are maintained.Q: What types of components are most suitable for this repair method?

A: This technique is ideal for Aluminium Bronze and Cast Iron components found in marine, industrial, and heavy machinery applications, especially where cold mechanical repair and rapid turnaround are essential.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Metal Stitching Category

Aluminium Piston Crack Repair

Price Range 160000.00 - 1300000.00 INR / Square Inch

Minimum Order Quantity : 1 , , Square Inch

Metal Stitching

Price Range 190000.00 - 3500000.00 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Crack Repair by Metal Locking and Metal Stitching Process

Price Range 260000.00 - 1300000.00 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Cylinder Liner/ Engine Block/ Crack Repair of MAN Main Engine/ Metal Lock and Metal Stitching

Price 122018 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS