Crankshaft Repair of MAN B&W 6L 16/24

Price 1000.0 INR/ Square Inch

Crankshaft Repair of MAN B&W 6L 16/24 Specification

- Experience

- Over 25 years in marine engine repair

- Custom Solutions

- Repairs tailored to client requirements

- Turnaround Time

- Fast and Reliable Service

- Applicable Engine Model

- MAN B&W 6L 16/24

- Service Type

- Crankshaft Reconditioning and Grinding

- Surface Finish

- Precision grinding ensures required surface finish

- Availability

- 24/7 Emergency Support

- Service Offered

- Crankshaft Repair

- Field Service

- Experienced technicians available for onsite repairs

- Repair Tolerance

- As per OEM specifications

- Product Name

- Crankshaft Repair of MAN B&W 6L 16/24

- Repair Method

- Onsite and Workshop Repair

- Inspection Method

- Magnetic Particle Inspection and Ultrasonic Testing

- Application

- Marine and Industrial Engines

Crankshaft Repair of MAN B&W 6L 16/24 Trade Information

- Minimum Order Quantity

- 1 Square Inch

- Supply Ability

- 1 Square Inch Per Day

- Delivery Time

- 2-3 Days

About Crankshaft Repair of MAN B&W 6L 16/24

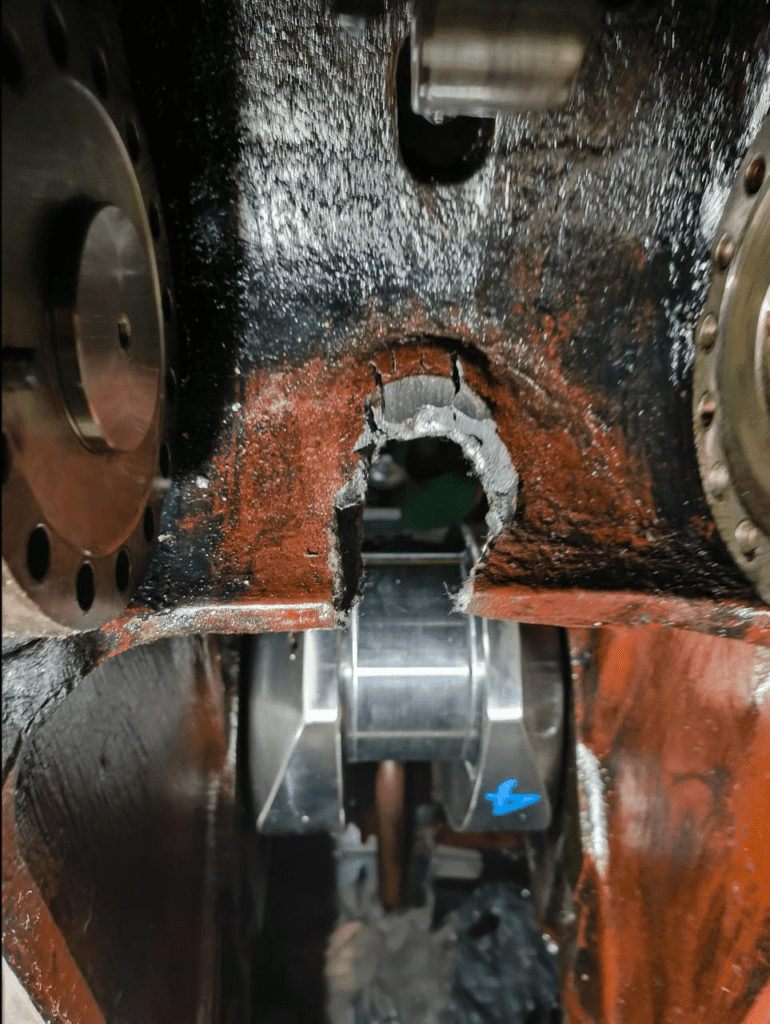

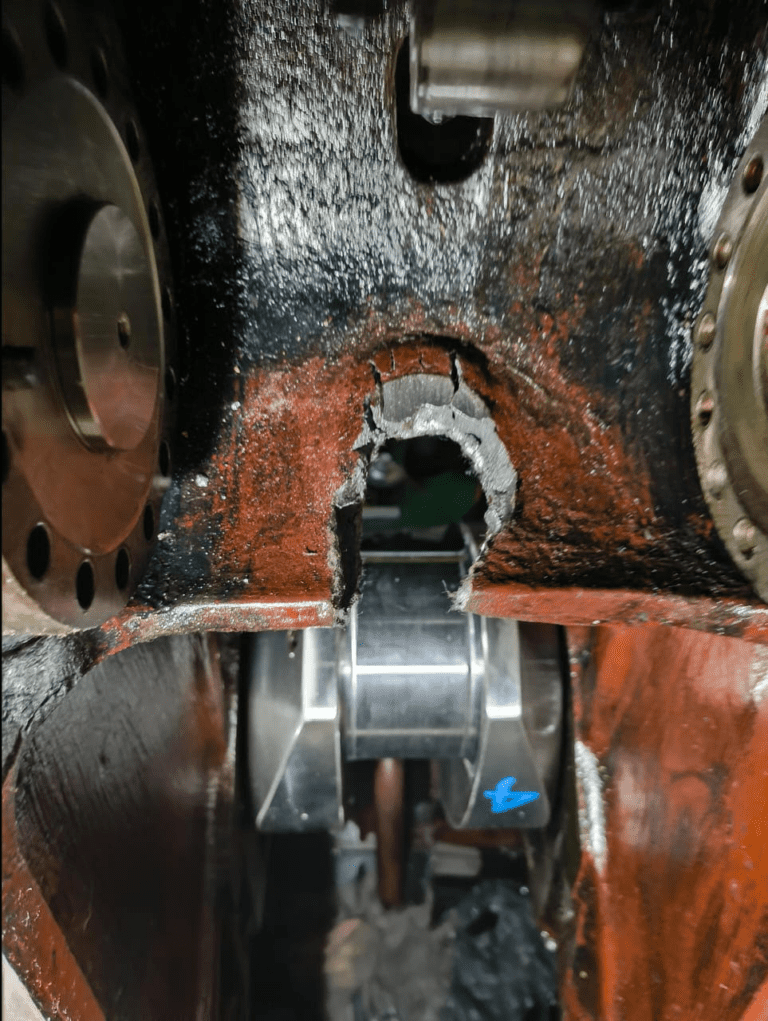

Major accident took place in the case of Auxiliary Engine MAN B&W 6L 16/24 on board a vessel owned by a leading Malaysian shipping company. The photographs of the damaged engine block and crankshaft were shared with RA Power Solutions.

Considering the serious damage to the Auxiliary Engine MAN B&W 6L 16/24, a team of three (3) technicians was deputed, which consisted of a Senior Metal Stitching Engineer and Two (2) technicians torepair the crankshaft.

The vessel was boarded by our technicians in Pasir Gudang. Following are the main details of the engine:

| S. No | Crankpin Details | |

| 1. | Engine Make | MAN B&W |

| 2. | Engine Model | 6L 16/24 |

| 3. | Crankpin Diameter Standard | 130.00 MM |

| 4. | Crankpin Bearing Width | 56.00 MM |

| 5. | Place of Execution of Grinding of Crankpin | Pasir Gudang Anchorage, Malaysia |

| 6. | Name of Shipping Company | Reputed Company from Kuala Lumpur |

Inspection of Crankshaft:

- All the crankpins were inspected dimensionally, and line marks and ovality were observed on all the crankpins. The standard diameter of crankpin was 130.00 MM.

- All other parameters, like hardness, and crack detection by MPI, were found within limits.

- On visual inspection of the radius fillet of two (2) crankpins was found damaged.

Inspection of Engine Block

- The Engine Block window seating area of Unit number #04 (Port Side) was found badly damaged.

- The Cam Case was also found broken.

Few Photographs of damaged Cam Case are given below:

| Broken Camshaft Area of the Window | Damaged Window cover Sittting Area |

|  |

Action Taken by RA Power Solutions to Repair of Crankshaft and Engine Block of MAN B&W 6L 16/24

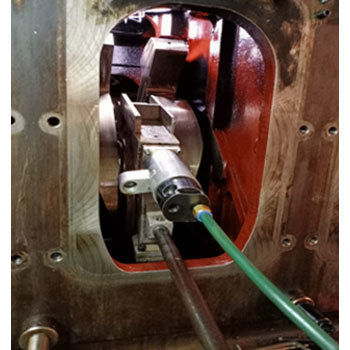

i. Considering the damage, all six (6) crankpins diameter was reduced from 130.00 Mm to 129.50 MM, maintaining the tolerance of 0.02 MM.

A copy of the report indicating the final dimensions is pasted below:

| SIZE OF CR PINS AFTER REPAIR | |||||||||

| A | Aa | C | Cc | B | Bb | Min | US

(0.50 MM)

| Ovality | |

| CR-1 | 129.48 | 129.49 | 129.49 | 129.48 | 129.50 | 129.50 | 129.48 | 129.50 | 0.02MM |

| CR-2 | 129.48 | 129.49 | 129.50 | 129.49 | 129.48 | 129.49 | 129.48 | 129.50 | 0.02MM |

| CR-3 | 129.49 | 129.50 | 129.50 | 129.48 | 129.49 | 129.50 | 129.48 | 129.50 | 0.02MM |

| CR-4 | 129.48 | 129.49 | 129.48 | 129.50 | 129.48 | 129.50 | 129.48 | 129.50 | 0.02MM |

| CR-5 | 129.49 | 129.49 | 129.48 | 129.50 | 129.48 | 129.49 | 129.48 | 129.50 | 0.02MM |

| CR-6 | 129.48 | 129.49 | 129.49 | 129.50 | 129.50 | 129.48 | 129.48 | 129.50 | 0.02MM |

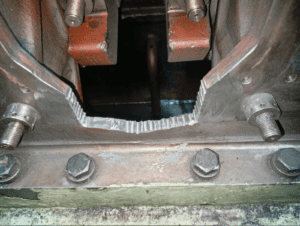

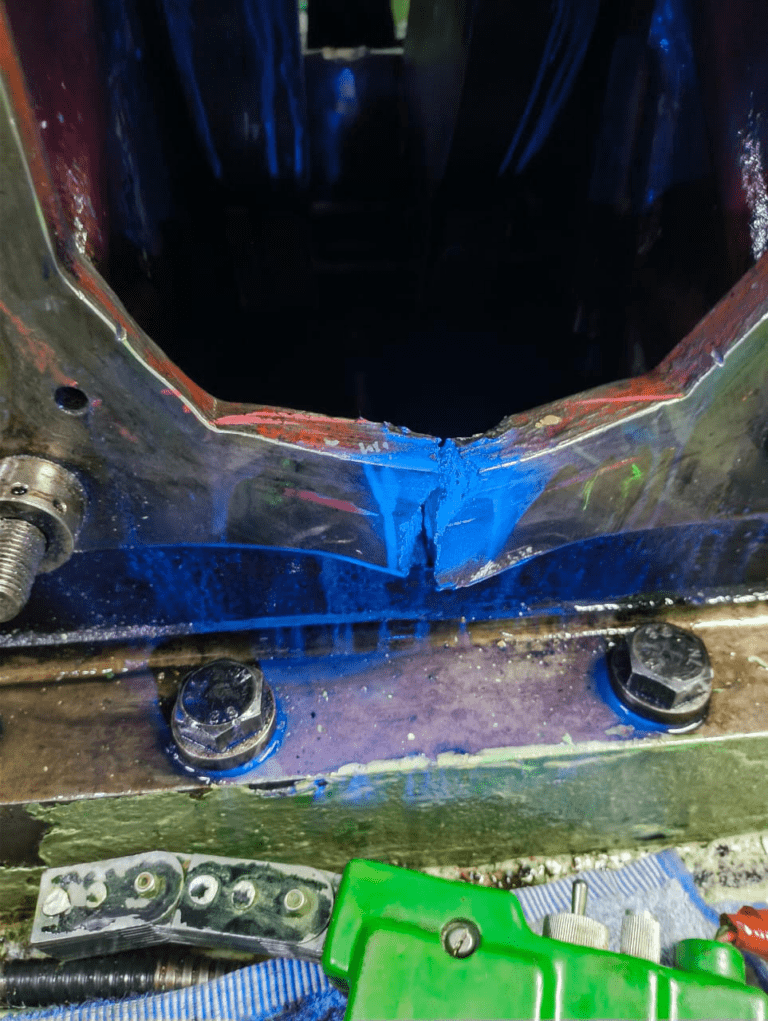

ii. The broken engine block was repaired by Metal Stitching Process. The new pieces of casting weremetal stitchedas shown in the photographs.

| Initial Cut Given in Engine Block Window Area | Fitment of New Casting in Damaged Area |

|  |

| MAN B&W Model No.6L 16/24 during metal lock | Metal locking of broken area of MAN B&W Model No.6L 16/24 |

|  |

iii) The Undersize bearings were also supplied by RA Power Solutions.

iv) The Engine was commissioned in the presence of our technicians and performance was found satisfactory.

| Pasting of Casting by Metal Lock Process | Perfect Matching of Casting After Metal Locking |

|  |

| Cam Cover Area Metal Stitched |

|

We have been regularly executingon site crankshaft repairsandIn Situ Crankshaft Grindingin Dubai, Fujairah, Qatar, Saudi Arabia, Oman, Iraq, Togo, Malta, Freetown, Egypt, Malaysia, Iran, Indonesia, Vietnam, Jordan, etc.

For more details of the Damaged Engine Block byMetal Stitching Process, please email us at info@rapowersolutions.com or Call at+91 9582647131, or+91 9810012383.

Expert MAN B&W 6L 16/24 Crankshaft Restoration

Entrust your engine's performance to a team with over 25 years' experience in repairing and reconditioning crankshafts for MAN B&W 6L 16/24 models. From emergency breakdowns to scheduled maintenance, we use industry-leading techniques and adhere to strict OEM tolerances, ensuring each crankshaft meets or surpasses required performance standards for marine and industrial settings.

Comprehensive Inspection and Rapid Turnaround

We utilize Magnetic Particle Inspection and Ultrasonic Testing to identify and address faults with accuracy. This approach guarantees that all necessary repairs are pinpointed and completed efficiently. Our flexible service model is designed to minimize downtime, delivering fast and reliable repairs either onsite or at our fully equipped workshops.

FAQ's of Crankshaft Repair of MAN B&W 6L 16/24:

Q: How is the crankshaft of MAN B&W 6L 16/24 inspected before repair?

A: Each crankshaft undergoes thorough Magnetic Particle Inspection and Ultrasonic Testing to accurately detect cracks, surface flaws, and internal defects prior to any repair work.Q: What is the typical process for crankshaft repair of MAN B&W 6L 16/24 engines?

A: The process includes detailed assessment, precision grinding to achieve the required surface finish, reconditioning within OEM-specified tolerances, and final validation to ensure restored performance.Q: When is onsite crankshaft repair available for MAN B&W 6L 16/24 engines?

A: We offer 24/7 emergency onsite support, enabling immediate response to repair needs at any location, minimizing downtime for your marine or industrial engine operations.Q: Where can the crankshaft repairs be performed?

A: Repairs can be executed either at your site by our experienced field technicians or in our advanced workshop, catering to the specific requirements and urgency of your operations.Q: What are the benefits of choosing your crankshaft repair service for MAN B&W 6L 16/24?

A: Clients benefit from rapid turnaround, precision repairs based on OEM standards, tailored solutions, and the assurance of over 25 years of marine engine expertise.Q: How does your service ensure the correct surface finish on repaired crankshafts?

A: We utilize advanced precision grinding techniques to achieve the required surface finish, ensuring optimal performance and longevity of the repaired crankshaft.Q: What makes your solutions customizable for different client requirements?

A: Our service approach is flexible, adapting repair methods and site of service to meet your specific needs, including custom machining and reconditioning strategies to address unique operational challenges.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Crankshaft Repair Category

Wartsila vasa 32LN Engine Crankpin Repair

Price 1600 USD ($) / Number

Minimum Order Quantity : 1 Square Inch

Onsite Crankshaft Repair by Ra Power

Price 13000 INR / Number

Minimum Order Quantity : 1 Square Inch

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS