MAN B&W 18V23L-V0 Crankshaft Repair in Zanzibar, Tanzania

Price 10000.0 INR/ Unit

MAN B&W 18V23L-V0 Crankshaft Repair in Zanzibar, Tanzania Specification

- Location

- Zanzibar, Tanzania

- Maximum Diameter

- Up to 1000 mm

- Crankcase Cleaning

- Included

- Service Availability

- 24/7 Emergency Support

- Technician Certification

- Class Certified Engineers

- Service Type

- Crankshaft Repair

- Contact

- +255 xxxx xxxx

- Inspection

- Ultrasonic and Magnetic Particle

- Lead Time

- 2-7 Days (Depending on Damage)

- Documentation

- Repair Report & Measurements Provided

- Application

- Marine Engine

- Surface Finish

- Ra 0.4-0.8 µm

- Tool Type

- Portable Machining Equipment

- Engine Model

- MAN B&W 18V23L-V0

- Repair Method

- Onsite Machining and Grinding

- Repair Tolerance

- Within OEM Specifications

- Product Name

- MAN B&W 18V23L-V0 Crankshaft Repair

- Material

- Alloy Steel

About MAN B&W 18V23L-V0 Crankshaft Repair in Zanzibar, Tanzania

MAN B&W 18V23L-V0 Main Engine on board the vessel at Zanzibar, Tanzania, had a major accident, damaging the crankshaft, cylinder liners, piston, and other parts. RA Power Solutions was approached by the leading shipping company based in Zanzibar, Tanzania to inspect the damaged crankshaft and repair if possible.

The crankshaft and Main Journal details are as follows:

| S. No. | Crankpin and Main Journal Details | |

| 1. | Engine Make | MAN B & W |

| 2. | Engine Model | 18V23L-V0-220 |

| 3. | Crankpin Diameter Standard | 185.00 MM |

| 4. | Crankpin Bearing Width | 78+78 MM |

| 5. | Main Journal Diameter | 220.00 MM |

| 6. | Main Journal Bearing Width | 112.00 MM |

| 7. | Place of Execution of Grinding of Crankpin | Zanzibar Anchorage |

| 8. | Name of Shipping Company | Reputed Company from Zanzibar, Tanzania |

Inspection Conducted by RA Power Solutions of Crankshaft of MAN B&W 18V23L-V0

|

Inspection of MAN B&W 18V23L-V0 Crankshaft Inspection of MAN B&W 18V23L-V0 Crankshaft |

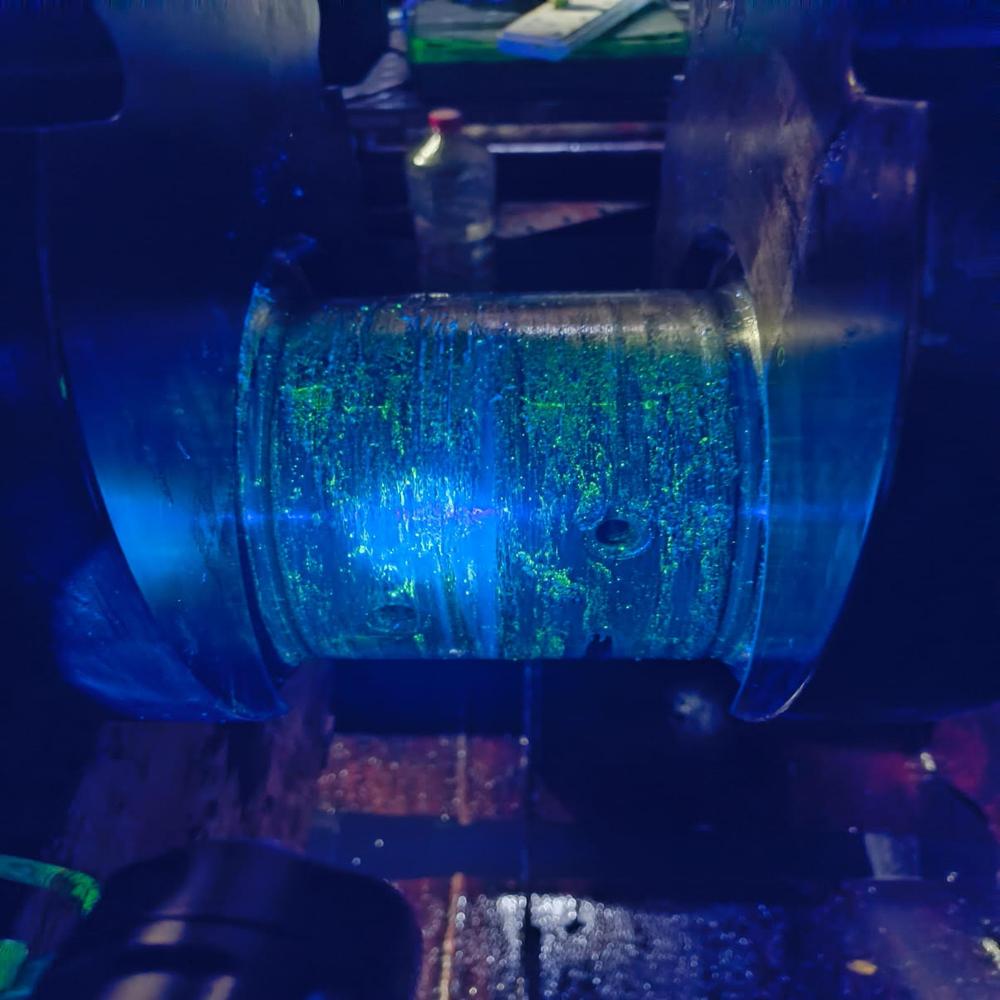

MPI Test of MAN B&W 18V23L-V0 Crankshaft MPI Test of MAN B&W 18V23L-V0 Crankshaft |

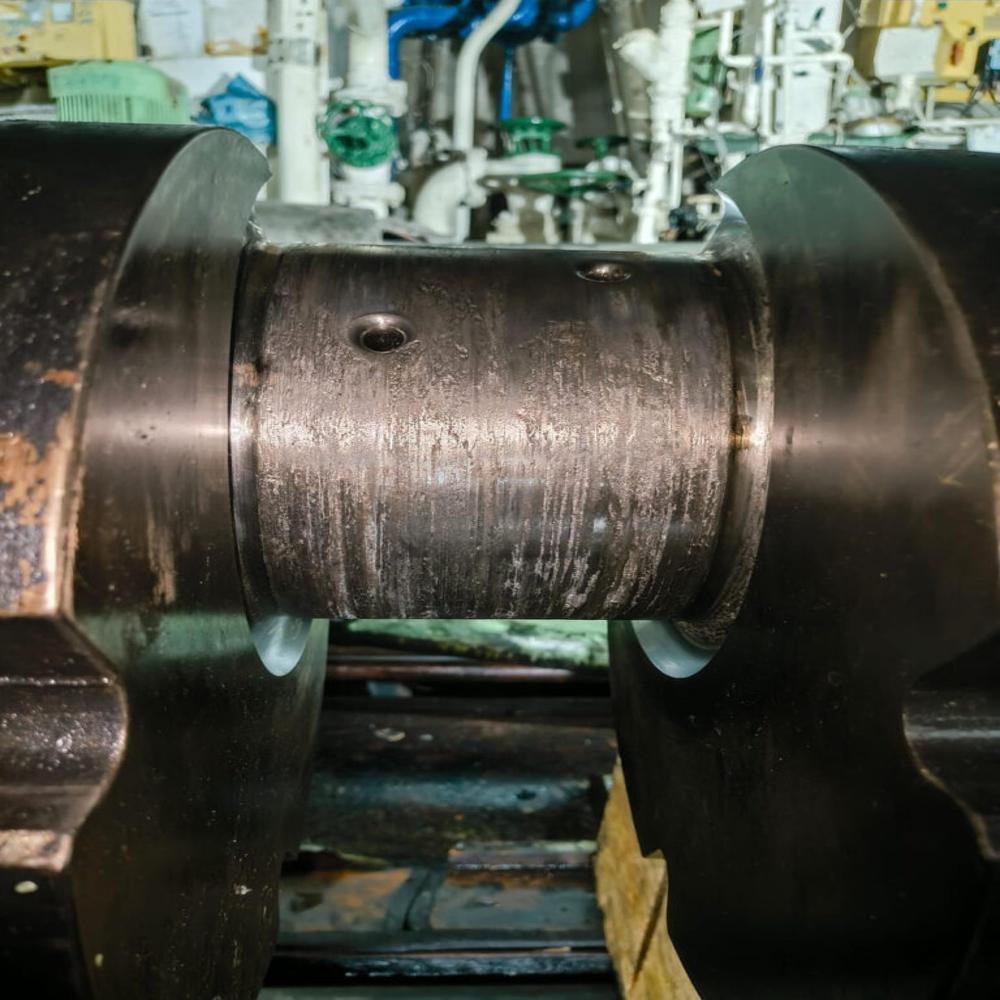

i) On the Visual Inspection of the crankpin and main journal of the crankshaft, the damage of bearing was clearly seen; in fact, the bearing material was also found in the oil sump.

It was decided to remove the crankshaft from the engine block in order to thoroughly inspect crankpin and main journal diameter of the crankshaft. The main journal housing also required thorough inspection for any cracks, deviation in the main journal housing bore, and the alignment of the housing.

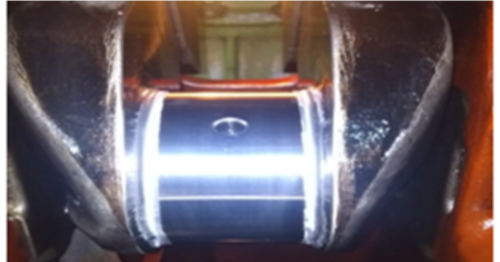

ii) The crankshaft was placed on the V block, the design of which was made by our technicians.

iii) The inspection in detail was conducted, including dimensional inspection report, MPI test for crack detection, Hardness test etc.

iv) While all the major parameters were observed within the limit. The crankpin Number #05, having a standard diameter of 185.00 and Main Journal Number #10, having a standard diameter of 220.00 MM, had excessive ovality, The deep line marks were also observed.

|

MAN B&W 18V23L-V0 Crankshaft Under Inspection MAN B&W 18V23L-V0 Crankshaft Under Inspection |

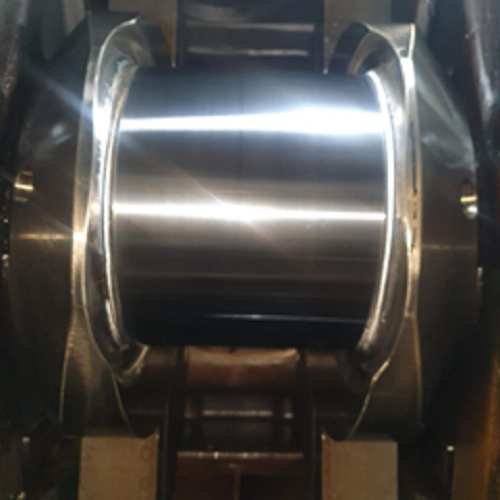

MAN B&W 18V23L-V0 Crankshaft Under Grinding and Polishing MAN B&W 18V23L-V0 Crankshaft Under Grinding and Polishing |

Action Taken by RA Power Solutions to Repair the Crankshaft of MAN B&W 18V23L-V0

i) The crankpin grinding was executed, the standard diameter of 185.00 was reduced by 1.5 MM, and the final diameter of 183.50 MM was maintained.

ii) The main journal diameter of 220.00 MM was reduced by 1.00 MM after grinding, and the final diameter was maintained as 219.00 MM.

iii) All the tolerance, surface finish, etc, were maintained strictly as per the manufacturers specifications stipulated in the manual.

We have been regularly executing on site crankshaft repairs and In Situ crankshaft grinding in Dubai, Fujairah, Qatar, Saudi Arabia, Oman, Iraq, Togo, Malta, Freetown, Egypt, Malaysia, Iran, Indonesia, Vietnam, Jordan, etc.

We have a team of trained technicians available 24/7 hrs and can be deputed in short notice. Some of our technicians also have a valid US VISA and can fly to South America, Caribbean countries, etc.

Comprehensive Onsite Crankshaft Repair

Experience professional onsite machining and grinding for the MAN B&W 18V23L-V0 engine. Our services in Zanzibar meet the highest industry standards, utilizing state-of-the-art portable machining equipment to minimize downtime and maximize reliability for marine applications.

Certified Technicians and Precision Inspection

All repairs are handled by class-certified engineers, ensuring work adheres strictly to OEM specifications. Ultrasonic and magnetic particle inspections are performed to guarantee crack-free results and long-lasting performance, giving you complete peace of mind.

24/7 Emergency Services and Swift Turnaround

Time-critical repairs are available around the clock, with an average lead time of just 2 to 7 days depending on the extent of damage. This rapid response, coupled with thorough cleaning and detailed reporting, makes us the preferred choice for crankshaft maintenance.

FAQ's of MAN B&W 18V23L-V0 Crankshaft Repair in Zanzibar, Tanzania:

Q: How is the onsite crankshaft repair for the MAN B&W 18V23L-V0 conducted in Zanzibar?

A: Our onsite machining and grinding process utilizes advanced portable equipment to restore crankshafts directly on your vessel, minimizing disassembly and downtime. The repair maintains OEM tolerances and ensures optimal functionality.Q: What inspection methods are used to verify the quality of crankshaft repairs?

A: We perform both ultrasonic and magnetic particle inspections to detect any cracks or internal flaws in the crankshaft, ensuring structural integrity and compliance with OEM and safety standards.Q: When can I request emergency crankshaft repair services in Zanzibar?

A: Our team is available 24/7 for emergency service requests. Simply contact us at +255 xxxx xxxx, and our certified engineers will respond promptly to assess and address your needs.Q: Where does the crankshaft repair service take place for marine engines?

A: The entire repair process is carried out onsite in Zanzibar, Tanzania, directly on your vessel or at your designated location, reducing the need for transportation and expedites the repair timeline.Q: What benefits does your MAN B&W 18V23L-V0 crankshaft repair service offer?

A: Our service minimizes vessel downtime, ensures crankshaft longevity through precise machining, delivers a premium surface finish (Ra 0.4-0.8 m), provides thorough inspection and documentation, and includes crankcase cleaning as part of every repair.Q: Which equipment and standards are used in your repair process?

A: Repairs are executed with advanced portable machining equipment, operated by class-certified engineers. All work is completed to OEM specifications and verified by comprehensive inspections and documentation.Q: What is included in the final documentation after crankshaft repair?

A: We provide a detailed repair report and precise measurement data, documenting all work performed and results achieved for full customer assurance and future reference.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Crankshaft Repair Category

Wartsila Crankshaft Repair and Crankshaft Grinding

Price 1500 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Wartsila Engine Model no. 6R32, 4R32, 8R32, 9R32, 12V32LN, 16V32D, 16V32LN, W16V32, W18V32 Crankpin Repair | Crankshaft Grinding Onsite

Price 5000 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Grinding of Crank Pin of Daihatsu Engine

Price 1500 INR / Square Inch

Minimum Order Quantity : 1 , , Square Inch

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free