On Site Grinding and Polishing of Wartsila Vasa 32LN Engine crankshaft

Price 16000 INR/ Square Inch

MOQ : 1 Square Inch

On Site Grinding and Polishing of Wartsila Vasa 32LN Engine crankshaft Specification

- Workforce Qualification

- Experienced technicians, class-certified

- Application

- Crankshaft grinding and polishing

- Service Location

- On Site (Remote / Marine / Industrial)

- Equipment Portability

- Fully portable, suitable for shipboard/remote applications

- Inspection Methods

- Ultrasonic, Magnetic Particle, and Visual Inspection

- Service Availability

- 24/7 Emergency Support

- Post-service Support

- Detailed inspection reports and after-sales consultation

- Surface Finish Achievable

- Ra 0.2-0.4 micron

- Service Name

- On Site Grinding and Polishing of Wartsila Vasa 32LN Engine Crankshaft

- Grinding Accuracy

- Within OEM Specifications

- Downtime Reduction

- Reduced by avoiding shaft removal

- Machine Type Used

- Portable On-Site Crankshaft Grinding Machine

- Engine Model

- Wartsila Vasa 32LN

- Crankpin/ Main Journal Tolerance

- Up to 0.01 mm

- Polishing Method

- Micro-polishing for surface finish

- Service Type

- Crankshaft Repair & Maintenance

On Site Grinding and Polishing of Wartsila Vasa 32LN Engine crankshaft Trade Information

- Minimum Order Quantity

- 1 Square Inch

- Supply Ability

- 1 Square Inch Per Day

- Delivery Time

- 2-3 Days

About On Site Grinding and Polishing of Wartsila Vasa 32LN Engine crankshaft

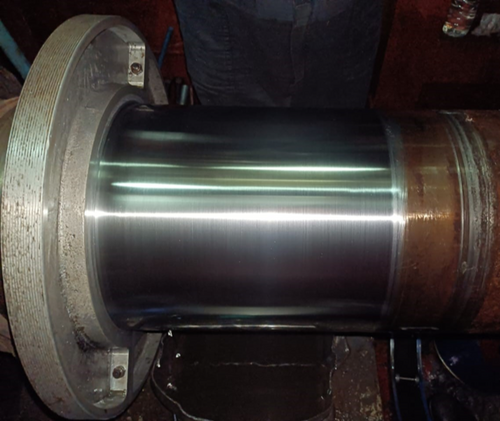

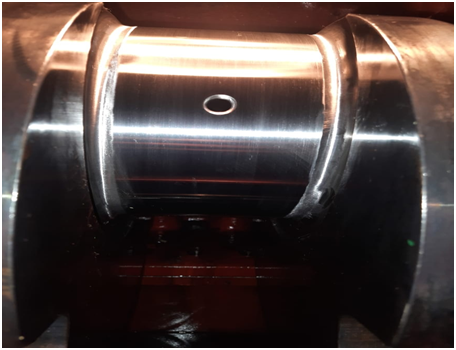

RA Power solution Pvt.Ltd. has recently executed successfully crankpin repair of Wartsila vasa 32LN engine. The crankpin having standard diameter of 270mm was damaged. The repair has been executed by undersizing the crankpin by 2mm.

We have been regularly executing on-site crankshaft repairs and crankshaft grinding in Iraq, Iran, Dubai, Oman, Saudi Arabia, Qatar, Abu Dhabi, Sharjah, Ajman, Umm Al-Quwain, Fujairah, Bahrain, Kuwait, Antigua and Barbuda, Belize, Dominica, Dominican Republic, Malaysia, Indonesia, Madagascar, Vietnam, Grenada, Guyana, Haiti, Jamaica, Saint Kitts and Nevis, Saint Lucia, South Korea, Saint Vincent and the Grenadines, Trinidad, and Tobago, etc.

For more details of repair of the Intermediate Shaft on site up to 700 mm diameter please visit our website https://www.

crankshaftgrindingrepair.com/ or email us on info@rapowersolutions.com Call at +91-9582647131,+91 9810012383.

Efficient On Site Crankshaft Restoration

We expertly restore Wartsila Vasa 32LN engine crankshafts directly at your site, utilizing portable grinding technology. This approach eliminates the need for shaft removal, saving both time and logistics costs. All work is executed to exacting tolerances and OEM standards, ensuring operational longevity and reliability for marine and industrial applications.

Advanced Surface Finishing and Polishing

Specialized micro-polishing techniques achieve exceptional surface finishes between Ra 0.2-0.4 micron. This fine finish is crucial to minimize wear and maximize performance in critical engine components. The portable equipment ensures consistent results whether on board ships or in remote industrial locations.

24/7 Support and Quality Assurance

Our team of experienced, class-certified technicians provides round-the-clock emergency assistance, comprehensive inspection methods, and thorough post-service documentation. We focus on delivering dependable service with minimal engine downtime, allowing you to maintain productivity and operational integrity.

FAQ's of On Site Grinding and Polishing of Wartsila Vasa 32LN Engine crankshaft:

Q: How does on site grinding and polishing benefit my Wartsila Vasa 32LN engine crankshaft?

A: On site grinding and polishing avoids the need for crankshaft removal, which significantly reduces downtime and transportation costs. It provides quick restoration to OEM tolerances, improving engine reliability and extending service life.Q: What surface finish and tolerance levels are achievable with this service?

A: We achieve a surface finish of Ra 0.2-0.4 micron and maintain crankpin/main journal tolerances within 0.01 mm, meeting OEM specifications for the Wartsila Vasa 32LN engine.Q: When should I consider using on site crankshaft grinding for my engine?

A: This service is essential whenever there is detected wear, scoring, or damage on the crankshaft journals. If measurements fall outside OEM tolerances or after an incident causing engine stress, prompt grinding and polishing restore functionality without extended docking periods.Q: Where can this service be provided?

A: Our portable equipment and skilled workforce allow us to deliver on site grinding and polishing at marine docks, shipboard locations, remote industrial sites, or any facility across India.Q: What is the typical process for on site crankshaft grinding and polishing?

A: The process involves thorough inspection using ultrasonic, magnetic particle, and visual methods, followed by precise in-situ grinding with portable machines. Micro-polishing techniques are applied to achieve the desired finish, and a detailed inspection report is provided post-service.Q: Who performs the grinding and polishing, and what qualifications do they hold?

A: All services are executed by experienced, class-certified technicians, ensuring all procedures align with OEM and class society requirements for safety and reliability.Q: What type of after-service support do you provide post-maintenance?

A: Our clients receive comprehensive inspection reports and access to consultation for after-sales support, ensuring ongoing engine health and performance.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS