Yanmar S185L-ST Crankshaft Repair

Price 1000.0 INR/ Square Inch

Yanmar S185L-ST Crankshaft Repair Specification

- Condition

- New

- Surface Treatment

- Precision Ground and Polished

- Product Name

- Yanmar S185L-ST Crankshaft Repair

- Model Number

- S185L-ST

- Packaging Type

- Wooden Box

- Hardness

- 56-62 HRC

- Material

- Forged Steel

- Color

- Metallic Silver

- Engine Type

- Marine Diesel Engine

- Usage

- Crankshaft Repair

- Compatible For

- Yanmar S185L-ST

- Application

- Ship Engine Overhaul and Maintenance

- Weight

- Approx 38 Kg

Yanmar S185L-ST Crankshaft Repair Trade Information

- Minimum Order Quantity

- 1 Square Inch

- Supply Ability

- 1 Square Inch Per Day

- Delivery Time

- 2-3 Days

- Certifications

- ISO 9001:2015 SEPC

About Yanmar S185L-ST Crankshaft Repair

Crankshaft Repair of Yanmar S185L-ST Crankshaft

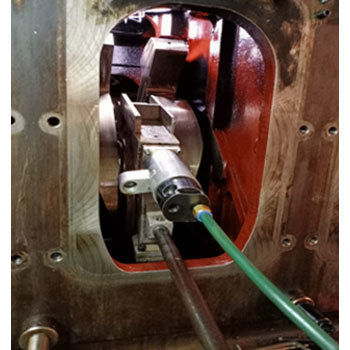

RA Power Solutions have facilities to undertake the grinding and polishing of crank pins and main journals having small bearing length. In order to undertake therepair of the crankpinand main journal having small bearing lengthobviously, it needs a crankshaft grinding tool which is compact indesignand can be placed on thecrankpinor main journaldiameter having smallbearing length.

We have been executing the repairs in Laos, Lebanon, Malaysia, Maldives, Mongolia, Nepal, North Korea, Oman, Philippines, Qatar, Russia, Saudi Arabia, Singapore, South Korea,SriLanka, Syria,United Arab Emirates,Yemen etc.

Exceptional Durability for Marine Applications

Constructed from forged steel and treated through precision grinding and polishing, the Yanmar S185L-ST Crankshaft Repair ensures outstanding durability and wear resistance crucial for marine diesel engines. The robust surface treatment and metallic silver finish not only enhance performance but also prolong the service life during intensive marine operations.

Optimized for High Performance and Reliability

With a hardness range of 56-62 HRC, this crankshaft repair part guarantees reliable operation under high-load conditions common in ship engines. Each component is crafted for precise fitment to Yanmar S185L-ST engines and undergoes stringent quality checks to ensure exceptional compatibility, minimizing downtime and maximizing operational efficiency.

FAQ's of Yanmar S185L-ST Crankshaft Repair:

Q: How is the Yanmar S185L-ST Crankshaft Repair installed in a marine diesel engine?

A: The crankshaft repair process involves dismantling the engine, carefully replacing the defective crankshaft with the new precision-ground component, and reassembling the engine according to the manufacturer's guidelines. Installation should be performed by trained marine engineers to ensure correct alignment and secure operation.Q: What are the primary benefits of using a precision ground and polished crankshaft?

A: A precision ground and polished crankshaft provides a smoother surface for better oil retention, reduces friction and wear, and improves the overall efficiency and lifespan of the marine engine, contributing to superior reliability during operation.Q: When should a Yanmar S185L-ST engine undergo crankshaft repair or replacement?

A: Crankshaft repair is recommended during major engine overhauls or when there are signs of damage such as excessive vibration, misalignment, or wear detected in routine inspections. Regular maintenance schedules should always include checks of critical engine components like the crankshaft.Q: Where does the crankshaft repair part come from and how is it packaged?

A: Our Yanmar S185L-ST crankshaft repairs are manufactured in India using advanced forging and finishing techniques. Each crankshaft is securely packaged in a robust wooden box to ensure safe transport and delivery to shipyards or marine maintenance facilities.Q: What is the process used to ensure the desired hardness and durability of the crankshaft?

A: The crankshaft is manufactured from forged steel and subjected to controlled heat treatment processes to achieve a hardness of 56-62 HRC. This is followed by precision grinding and polishing for enhanced surface finish, ensuring optimal strength and resistance against wear.Q: Can this crankshaft repair part be used for applications other than marine diesel engines?

A: No, the Yanmar S185L-ST Crankshaft Repair is specifically engineered for Yanmar S185L-ST marine diesel engines. Using it in incompatible engines or settings can result in improper fitment and suboptimal performance.Q: What kind of clients typically use this crankshaft repair product?

A: This product is mainly utilized by ship owners, marine maintenance contractors, shipyards, and engine overhaul service providers that require reliable repair and replacement solutions for Yanmar S185L-ST marine diesel engines.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Crankshaft Repair Category

Crankshaft Repair/ Crankshaft Machining Services in Ecuador

Price 1500 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Onsite Crankshaft Repair by Ra Power

Price 13000 INR / Number

Minimum Order Quantity : 1 Square Inch

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS