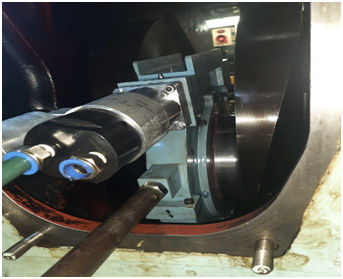

Crankpin Grinding

Price 132000 INR/ Unit

Crankpin Grinding Specification

- Rotation

- Left & Right

- Model

- CPG-700

- Product Type

- Crankpin Grinding Machine

- General Use

- Crankshaft And Crankpin Grinding

- Material

- Mild Steel

- Type

- Surface Grinding Machine

- Capacity

- 30 to 150 mm (Range of Pin diameter grinding)

- Weight (kg)

- Approx 3500 kg

- Computerized

- No

- Automatic

- No

- CNC Or Not

- Normal

- Control System

- Manual

- Table Size

- 900 mm x 180 mm

- Table Slide Way

- V & Flat Type

- Magnetic Chuck Size

- 500 mm x 50 mm

- Grinding Wheel Size

- 455 mm x 50 mm x 228.6 mm

- Grinding Wheel Speed

- 1000 RPM

- Grinding Length

- 700 mm

- Floor Space

- 4000 mm x 2560 mm

- Fuel Tank Capacity

- 40 Ltr.

- Spindle Speed

- 45 RPM

- Power

- 5 kW

- Voltage

- 380 V

- Dimension (L*W*H)

- 4000 mm x 2560 mm x 1600 mm

- Feature

- High Precision, Durable, Compact Design

- Color

- Blue & White

Crankpin Grinding Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Day

- Delivery Time

- 2-3 Days

- Main Export Market(s)

- Western Europe, Eastern Europe, Middle East, Central America, South America, Asia, North America, Australia, Africa

- Certifications

- ISO 9001:2015 SEPC

About Crankpin Grinding

Crankpin Grinding

RA Power Solutions having experience of more than four decades has emerged as leaders in providing services for onsite crankshaft grinding, crankshaft repair and crankpin reconditioning in Asia, Middle East, South America, Parts of Europe and many countries all over the world.

The combination of the latest design of onsite crankshaft grinding machine possessed by RA Power solutions and experienced technicians who have collectively repaired more than 10,000 crankshafts gives the confidence to our clients for successful repairs of crankshaft once the job is entrusted to RA Power Solutions.

Following are the main abnormalities observed in the crankshaft which requires Crankshaft repair

Bearing line marks and development of rough surface.

Damage of radius fillet, lubricating oil hole due to an accident.

Development of taper and ovality beyond the limits specified by the engine manufacturers.

Increase in hardness beyond the permissible limit due to overheating.

Cracks observed on crank pins and main journal.

Crankshaft Grinding & Repair process followed by RA Power Solutions

Dimensional inspection of crankshaft in detail is undertaken by RA Power technicians.

Hardness check of damaged CR Pin or main journal of Crankshaft is conducted.

Crack detection by MPI, dye penetrant or ultrasonic crack detection is done.

Visual inspection

The inspection report in detail is studied by our senior technicians and the necessary planning for onsite repair is done. The onsite crankshaft grinding and polishing is undertaken by RA Power Solutions in the shortest possible time.

Precision Grinding for Industrial Demands

The CPG-700 is designed to address the rigorous demands of crankshaft and crankpin grinding in automotive and industrial engine maintenance. With a capacity to accommodate crankpins up to 150 mm in diameter and 700 mm in length, it offers precise, efficient operation for both repair and manufacturing applications. Its variable working speed and robust electric drive help maintain superior grinding consistency.

Advanced Cooling and Lubrication

Ensuring both safety and machine longevity, the integrated coolant system efficiently dissipates heat during operation, minimizing thermal expansion and ensuring smoother finishes. Coupled with an automatic lubrication system, the CPG-700 reduces wear and tear, keeping maintenance to a minimum and extending the service life of critical components.

Ease of Use and Durability

Built with reliability in mind, this surface grinding machine features manual controls, a sturdy V & Flat type table slide way, and a compact, efficient layout. The high-capacity fuel tank and durable construction make it suitable for continuous operation in demanding industrial settings, while the simple color-coded manual system supports operator accuracy and ease of use.

FAQ's of Crankpin Grinding:

Q: How does the CPG-700 ensure high-precision crankpin grinding?

A: The CPG-700 uses a robust structure, accurate manual control system, and variable working speeds to achieve high precision in grinding crankpins with diameters ranging from 30 mm to 150 mm. Its magnetic chuck and stable table slide way facilitate secure and accurate positioning during operation.Q: What is the cooling process during grinding, and why is it important?

A: The machine includes a coolant system that continuously circulates fluid over the grinding area, effectively reducing heat generation during the process. This protects both the crankpin and grinding wheel from thermal damage, enhancing surface quality and prolonging equipment lifespan.Q: When should the automatic lubrication system be checked or maintained?

A: The automatic lubrication system is designed for minimal intervention, but it is recommended to inspect and top up lubricant levels during routine maintenance checks, or whenever there is a drop in system performance, to ensure smooth operation and reduce component wear.Q: Where can the CPG-700 be used, and what industries is it best suited for?

A: This grinding machine is ideal for use in automotive workshops, engine repair centers, and manufacturing facilities dealing with automobiles and industrial engines. Its robust design is suitable for both repair and production environments.Q: What is the general process of grinding a crankpin using this machine?

A: Operators securely mount the crankshaft on the machine, adjust the manual controls for the desired parameters, and use the V & Flat table slide way for accurate movement. The coolant system operates throughout, ensuring optimal temperature control as the grinding wheel shapes the crankpin.Q: How does variable working speed benefit the user?

A: Variable working speed allows operators to adjust the grinding parameters to match different materials and grinding requirements, leading to improved finish, reduced wheel wear, and greater flexibility in handling various crankpin sizes and materials.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Crankshaft Grinding Category

Crankshaft Grinding And Crankpin Machining

Price 134000 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : Other, High rigidity; long service life; precise machining

Type : Other, Crankshaft and Crankpin Grinder

Model : CGCP1600

Automatic : Other, SemiAutomatic

Crankshaft Repair While Sailing

Price 134000 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : Other, Onboard repair capability, portable design

Type : Other, Portable

Model : CRS2500

Automatic : No

Crankshaft Grinding of Yanmar

Price 90000-1600000.00 INR / Unit

Minimum Order Quantity : 1 , , Unit

Feature : Other, High Precision, Durability

Type : Other, External Grinding Machine

Model : Yanmar Compatible

Automatic : No

Wartsila Crankshaft Grinding on Ship

Price 13500 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Feature : Other, Shipboard use, Portable, Precision Grinding

Type : Other, Portable OnBoard Grinding

Model : Wartsila OnShip Portable Grinder

Automatic : No

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS