Crankshaft Repair While Sailing

Price 134000 INR/ Unit

Crankshaft Repair While Sailing Specification

- Rotation

- Clockwise/Counterclockwise

- Model

- CRS-2500

- Product Type

- Crankshaft Grinding Machine

- General Use

- Crankshaft Repair while Sailing

- Material

- Steel / Alloy

- Type

- Portable

- Capacity

- Up to 500 mm diameter crankshafts

- Weight (kg)

- 700 kg

- Computerized

- No

- Automatic

- No

- CNC Or Not

- Manual

- Control System

- Hydraulic / Manual

- Table Size

- Customizable

- Table Slide Way

- V & Flat guideways

- Magnetic Chuck Size

- Standard

- Grinding Wheel Size

- Custom

- Grinding Wheel Speed

- Variable (up to 2500 rpm)

- Grinding Length

- Variable up to 2500 mm

- Floor Space

- Compact, suitable for ship deck

- Spindle Speed

- Variable (100-1500 rpm)

- Power

- 3-5.5 kW

- Voltage

- 220V / 380V

- Dimension (L*W*H)

- 1800mm x 850mm x 1200mm

- Feature

- On-board repair capability, portable design

- Color

- Blue / Silver

Crankshaft Repair While Sailing Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Others

- Supply Ability

- 10 Units Per Day

- Delivery Time

- 2-3 Days

- Certifications

- ISO 9001:2015 SEPC

About Crankshaft Repair While Sailing

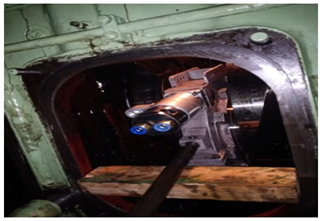

Crankshaft repair by grinding and polishing is now possible while vessel is on move. RA Power Solutions Pvt. Ltd. is the first company to offer crankshaft repair services while vessel is sailing by onsite portable crankshaft grinding equipment which is taken on board the vessel. The crankshaft repair is undertaken by vibration free crankshaft grinding machine without removing the crankshaft from the engine block thus saving time and cost

RA Power Solutions Pvt. Ltd. undertakes onsite crankshaft grinding and polishing on board the vessel while sailing up to 700 mm diameter

RA Power Solutions Pvt. Ltd. has recently undertaken grinding of all 6 CR pins of MAN B&W STX 6L23/30H while sailing of vessel between ports of Malaysia and Indonesia. The crankpins were damaged due to lack of lubrication oil and all the pins were undersized by 0.5 mm. The tolerances after grinding and polishing have been maintained as per the manufacturers requirements.

RA Power Solutions Pvt. Ltd. has designed vibration free onsite crankshaft grinding and crankshaft polishing equipment by which it is possible to execute crankshaft repair while ship is on move.

Portable Repair Solution for Marine Engines

The CRS-2500 crankshaft repair machine brings efficient, reliable servicing directly onto ships. Its weatherproof, compact design and deck portability keep marine engines running without docking delays. Integrated water cooling and centralized lubrication systems guarantee safe, quiet operations while sailing, facilitating high-precision maintenance for shipboard environments.

Precision Craftsmanship on the Move

Achieve surface finishes as fine as Ra 0.3 m for crankshafts up to 2,500 mm in length. This machine uses standard magnetic chucks and custom grinding wheels, coupled with variable speeds for both spindle and grinding. The hydraulic/manual controls, stable guideways, and single-operator capability ensure consistent repair quality for marine or auxiliary machinery.

Safe and Adaptable Operation

Featuring overload protection with centralized lubrication and water cooling, the CRS-2500 ensures safe operation aboard ships. The compact design fits limited floor spaces found on decks, boasts noise levels below 80 dB, and supports weatherproof case packaging. Its manual system adapts readily to either clockwise or counterclockwise rotations, backed by robust steel or alloy materials.

FAQ's of Crankshaft Repair While Sailing:

Q: How can the CRS-2500 be used for crankshaft repairs while sailing?

A: The CRS-2500 is specifically designed for portable, on-board crankshaft repairs in marine environments. Its compact, weatherproof build and deck mobility allow single operators to perform repairs even while a ship is at sea, minimizing downtime by removing the need to return to port.Q: What benefits does integrated water cooling and centralized lubrication provide?

A: The CRS-2500 uses integrated water cooling and centralized lubrication to maintain optimal operating temperatures and reduce mechanical wear. This ensures high-quality machining, protects against overheating, and extends the lifespan of both the device and the engine parts being repaired.Q: When should I use the CRS-2500 for marine crankshaft maintenance?

A: This machine is ideal for scheduled maintenance, emergency repairs, or overhaul situations when immediate, on-site servicing of marine engine or auxiliary equipment crankshafts-up to 2,500 mm in length-is required during voyages or in remote locations.Q: Where on a ship can the CRS-2500 be operated?

A: Thanks to its portable design and compact footprint, the CRS-2500 can be set up and operated directly on the ship's deck or in engine rooms with limited floor space. Weatherproof cases ensure the machine remains protected during transport or when not in use.Q: What is the process for repairing a crankshaft using this machine?

A: A single operator positions the standard magnetic chuck and custom grinding wheel against the crankshaft, selects variable speeds for both spindle and wheel, and manually controls the hydraulic system. Integrated cooling and lubrication systems run throughout, while overload protection guards against excessive force.Q: How does the CRS-2500 ensure safety during operation?

A: The machine includes overload protection to prevent mechanical or electrical mishaps. Noise levels are kept below 80 dB, and the centralized lubrication system ensures that moving parts operate smoothly, reducing the risk of operator injury and equipment damage.Q: What advantages does on-board repair capability provide for marine operators?

A: On-board repair capability enables immediate response to maintenance needs, minimizes costly delays, and supports uninterrupted voyages. The CRS-2500's portability, weatherproof packing, and suitability for single-operator use make it an efficient solution for shipboard crankshaft repair, reducing operational expenses and downtime.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Crankshaft Grinding Category

Crankpin Grinding

Price 132000 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : Other, High Precision, Durable, Compact Design

General Use : Crankshaft And Crankpin Grinding

Type : Surface Grinding Machine

Material : Other, Mild Steel

Crankshaft Grinding And Crankpin Machining

Price 134000 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : Other, High rigidity; long service life; precise machining

General Use : Crankshaft and crankpin grinding and machining

Type : Other, Crankshaft and Crankpin Grinder

Material : Other, Heavyduty cast iron body

Crankshaft Grinding of Yanmar

Price 90000-1600000.00 INR / Unit

Minimum Order Quantity : 1 , , Unit

Feature : Other, High Precision, Durability

General Use : Crankshaft Grinding for Yanmar engines

Type : Other, External Grinding Machine

Material : Other, Cast Iron / Steel

Onsite Crankshaft Grinding

Price 130000 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : Other, Portable, High Precision, Easy setup

General Use : Crankshaft repair and grinding at site

Type : Other, Portable/Onsite Grinding Machine

Material : Other, Alloy Steel, Cast Iron

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS