Crankshaft Repair

Price 1500 INR/ Square Inch

MOQ : 1 Square Inch

Crankshaft Repair Trade Information

- Minimum Order Quantity

- 1 Square Inch

- Supply Ability

- 1 Square Inch Per Day

- Delivery Time

- 2-3 Days

About Crankshaft Repair

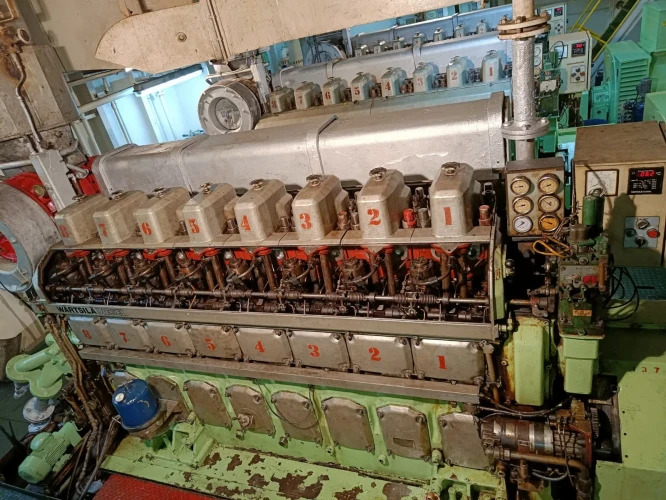

RA Power Solutions undertakes crankshaft repair of diesel engine used as generator, marine engine & auxiliary engine, compressor, forging hammers and all heavy rotatory equipment's having crankshaft or cylindrical shafts upto 700 mm diameter.We have been extending onsite crankshaft repair services for medium & heavy equipment's for over four decades and the services are extended all over the world. We also execute repairs of the crankshaft on a moving vessel and there is no requirement of holding it.

Advantages of crankshaft repair services offered by RA Power Solutions.

We are mentioning below few of the advantages of getting crankshaft repair executed by RA Power Solutions.

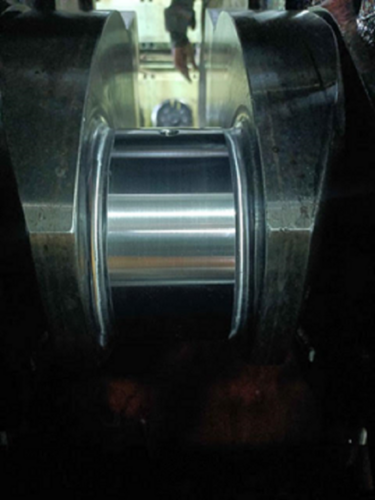

i) We believe that the crankshaft is a piece of art and even for the heavy crankshafts the tolerance in terms of taper and ovality ranges between 20 to 50 microns which is very less and requires experience, special skill and dedicated latest design of equipment to maintain.

ii) RA Power Solutions is the only manufacturer of the onsite crankshaft grinding machine in the world and has supplied over 70 machines which are in operation by leading shipping companies, Power Plants and repair workshops etc.

iii) Our designing and manufacturing of onsite crankshaft grinding machines for crankshaft repair can be easily modified according to the site requirement.

iv) Difficult and serious damage of crankshaft are successfully repaired as we have in-house capability of modifying our equipment as per the site requirement and condition.

v) Most of the companies based in Europe, UK undertaking crankshaft repair cannot successfully execute the repair of crankshaft radius fillet of which is damaged or worn out due to accident. They always recommended to either remove the crankshaft from the engine block and send it to the workshop or to reject it.

vi) We have onsite crankshaft grinding equipment by which repair of crankshaft can be successfully executed in spite of damage to the radius fillet of both sides. We have the record of more than thousands of crankshaft repair cases where the radius fillet was damaged.

vii) We have facilities and modern equipments to undertake non destructive tests including hardness check, crack detection check by MPI and dimensions check, etc.

Availability of trained & experienced technicians for crankshaft repair :

i) All our technicians are trained in our in-house training school near New Delhi, capital of India.

ii) The technicians are trained on dummy crankshafts under the senior supervisions, who has experience of 30 and 40 years in crankshaft repair.

iii) Our mission is to create awareness and make it understandable to our clients all over the world that it is not a difficult task to repair the crankshaft, which few companies have been propagating and made monopoly by charging exorbitant price.

Low cost of crankshaft repair offered by RA Power Solutions

We are the cheapest in the world executing crankshaft repair at minimum cost.

We don't charge separately for NDT test, cost for repair of radius fillet, out of station allowance etc.

We have successfully executed damaged crankshaft repair of MAN B&W, Yanmar, Daihatsu, Wartsila, Ruston & Hornsby Engine etc.

We have been regularly executing the repairs in Argentina, Bahamas, Barbados, Bermuda, Bolivia, Brazil, Canada, Chile, Colombia, Costa Rica, Cuba, Dominican Republic, Ecuador, El Salvador, Guatemala, Guyana, Haiti, Honduras, Jamaica, Mexico, Nicaragua etc.

Comprehensive Crankshaft Restoration

Our team offers expert crankshaft repair utilizing precise machining methods to restore even large-sized (up to 6000 mm) forged steel crankshafts. We ensure a mirror finish and high surface hardness, effectively prolonging crankshaft life for automobile engine applications.

On-Site and Workshop Flexibility

We understand the need for convenience and minimal downtime, offering crankshaft repair at your location or at our fully-equipped workshop. Our services are available 24/7, providing flexibility and rapid response to urgent repair requirements anywhere in India.

Maximum Strength & Durability Guaranteed

Using polished surface treatments and high-precision engineering, our repairs deliver crankshafts that possess high strength, rust-proofing, and durability. Each component is finished to stringent industry standards, ensuring reliable performance in demanding automotive environments.

FAQ's of Crankshaft Repair:

Q: How is the crankshaft repair process carried out?

A: Our crankshaft repair process begins with a detailed assessment, followed by precision machining, surface polishing, and hardening to HRC 60-63. We ensure a mirror finish and check for high-strength and rust-proof qualities before final approval.Q: What types of crankshafts can you service?

A: We service forged steel crankshafts up to 6000 mm in length, primarily for automobile engines. Our expertise covers both standard and complex configurations, providing solutions that meet diverse industry needs.Q: When should I consider crankshaft repair for my engine?

A: Consider crankshaft repair when signs of wear, scoring, or performance loss become evident in your automobile engine. Early intervention prevents severe engine damage and minimizes downtime.Q: Where can your crankshaft repair service be availed?

A: Our services are available across India, either on-site at your premises or at our dedicated workshop facility, depending on your preference and the complexity of the repair.Q: What are the key benefits of your crankshaft repair services?

A: Our services restore crankshafts to as-new specifications, providing enhanced durability, rust-proof properties, high strength, and a superior mirror finish. This ensures improved engine performance and extended component lifespan.Q: How do you ensure the quality of repaired crankshafts?

A: We employ advanced machining and polishing techniques, followed by rigorous quality checks to ensure correct hardness, finish, and durability. Our workshop adheres to strict industry standards for every repair project.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Crankshaft Repair Category

Insitu And Onsite Crankshaft Journal Repair/ Crankshaft Grinding/ RA Power Solutions

Price 1500 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Wartsila 8L20 Crankshaft Repair at Togo

Price 4000.0 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Crankshaft Repair Engine MAN 5L 16/24

Price 16000 USD ($) / Square Inch

Minimum Order Quantity : 1 Square Inch

Crankshaft Repair of MAN B&W 6L 16/24

Price 1000.0 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS