Crankshaft Repair Machine

Product Details:

Crankshaft Repair Machine Price And Quantity

- 1500 INR/Square Inch

- 1 Square Inch

Crankshaft Repair Machine Trade Information

- 1 Square Inch Per Day

- 2-3 Days

Product Description

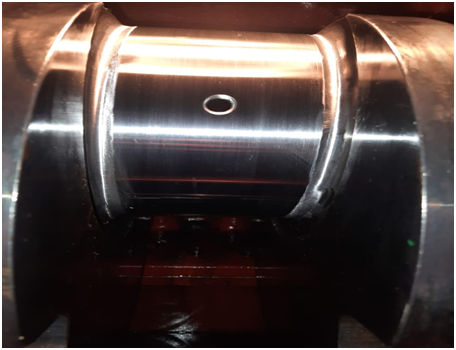

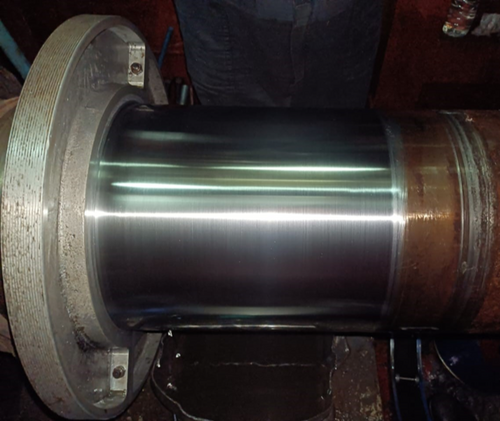

RA Power Solutions designs, develops and manufactures a complete range of crankshaft grinding and polishing machines, from small diameter of 30 mm to large diameter of 700 mm. These machines are used mainly for repair of damaged or burned out Crankshafts on site.

There is absolutely no requirement of removing the crankshaft from the block and sending it to the workshop when RA Power Solutions is called in to help & support. In fact, after the introduction of this onsite crankshaft grinding machine by RA Power Solutions, a number of companies having large bench type crankshaft grinding machines, have had to shut down their operations.

Crankshaft Grinding Machine with most advanced technology

With our experience of repairing of more than ten thousand crankshafts successfully in the last four decades we are able to design and produce crankshaft grinding machines with most advanced mechanical solutions.

Our concept and design is far ahead of the companies who are still using old technology of undertaking the grinding of crankpin & main journal by taking the reference of radius fillet.

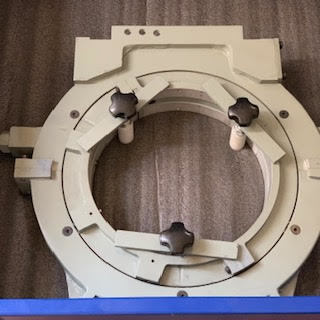

Structure of Crankshaft Grinding Machine :

The main body of the equipment is manufactured out of Titanium steel which provides capability of grinding heavy crankshafts with large crank pins and main journal diameters.

In spite of the strong structure of crankshaft grinding machine it is light weight, which facilitates the technicians to carry the machine to various sites all over the world.

The key features of this technology are as follows:

a) CNC Orbital grinding technology.

b) Linear motor technology.

c) In-process gauging.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+