Intermediate Shaft Repair and Rebabbitting of Intermediate Shaft Bearing

Price 6000.0 USD ($)/ Piece

Intermediate Shaft Repair and Rebabbitting of Intermediate Shaft Bearing Specification

- Cage Material

- Steel

- Precision Rating

- ISO standard

- Inside Diameter

- Varies with shaft

- Thickness

- As per requirement

- Retainer

- Steel retainer

- Lubrication Type

- Oil lubricated

- Bearing Type

- Intermediate Shaft Bearing

- Material

- Steel body with high-grade white metal (Babbitt) lining

- Structure

- Split Cylindrical

- Seals Type

- Open / Unsealed

- Number Of Rows

- Single Row

- Bore Size

- Custom sizes available

- Outside Diameter

- Custom sizes on request

- Limiting Speed

- Up to 3000 RPM

- Load Capacity

- High radial load

Intermediate Shaft Repair and Rebabbitting of Intermediate Shaft Bearing Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 2-3 Days

About Intermediate Shaft Repair and Rebabbitting of Intermediate Shaft Bearing

RA Power Solutions was approached by a leading shipping company based in Vietnam. The vessel was approaching Kochi Port India, and serious damage was reported to the intermediate shaft and bearing.

RA Power Solutions three technicians boarded the vessel and their main observations are as following:-

Intermediate Shaft

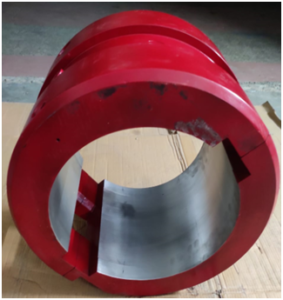

- On removal of Intermediate Shaft bearing the excessive damage to the bearing seating area was observed.

- The Intermediate Shaft bearing, babbitt white metal was badly stuck on the bearing journal diameter.

- After removal of white metal from the Intermediate Shaft bearing seating area the ovality of 0.38 MM was observed, and the standard diameter of Intermediate Shaft Journal is 505.00 MM.

- Hardness and MPI Tests were undertaken and observed within limits.

- Localized damage, Bearing line marks, and Rough surface were observed on Intermediate Shaft Journal diameter.

- Intermediate Shaft Journal diameter was repaired by in situ grinding and polishing machine and diameter was maintained as 504.00 MM. The intermediate shaft bearing seating diameter was reduced by 1.0 mm.

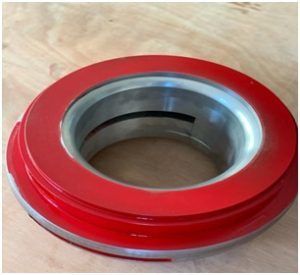

Repair of Intermediate Shaft Bearing

- After removal of damaged babbitt white metal Intermediate Shaft bearing from the vessel, it was transported to our works based in IMT Manesar near New Delhi by Air, A distance of more than 2600 KM from Kochi Port India.

- The inspection of damaged bearing was undertaken, the bearing was rebabbitted and machining was done maintaining the inner diameter of 504.50 MM, as per the oil gap mentioned in the manual.

- Bearing was again returned to the Kochi Port India and was hand-carried by our representative to save time.

Assembly of Intermediate Bearing and Shaft

- The bearing was Assembled by RA Power Solutions Technicians.

- All the parameters including Oil-gap and Blue Matching of the bearing was done with Intermediate Shaft.

- After assembly trials were taken, the performance of the Intermediate Shaft and bearing was observed satisfactory. The job was executed in a short duration of Eight (8) days.

Precision Shaft Repair for Maximum Reliability

Our shaft repair process restores intermediate shaft assemblies to peak operational standards. Precision machining, polishing, and component alignment guarantee a smooth operation and high radial load capacity, essential for heavy machinery usage. We perform repairs using quality materials and advanced procedures to maximize durability.

Rebabbitting for Extended Service Life

The rebabbitting of bearings incorporates high-grade white metal, poured under controlled temperatures to establish consistent purity and strength. Each bearing undergoes ultrasonic and dye penetrant testing, assuring integrity and safety. This process considerably improves wear resistance and bearing longevity in demanding environments.

Custom Fitment and Inspection Services

We offer tailored fitment for a variety of bore and outside diameters, accommodating client specifications. Our team ensures every assembly meets ISO precision ratings. Rigorous inspection routines, including non-destructive testing, reinforce reliability and minimize future downtime for maintenance.

FAQ's of Intermediate Shaft Repair and Rebabbitting of Intermediate Shaft Bearing:

Q: How is intermediate shaft repair performed for heavy machinery?

A: Intermediate shaft repair involves thorough assessment, precision machining, and complete restoration of the shaft assembly. Components are realigned, worn surfaces are rebuilt, and new Babbitt lining is poured under controlled conditions to achieve optimal operating standards and extended service life.Q: What is the process of rebabbitting shaft bearings?

A: The rebabbitting process includes removing the worn Babbitt lining, meticulously cleaning the steel body, and pouring high-purity white metal under strict temperature control. This is followed by precision machining and polishing to achieve the required dimensions and surface finish, ending with ultrasonic and dye penetrant inspections for quality assurance.Q: When should intermediate shaft bearings be inspected or replaced?

A: It is recommended to inspect intermediate shaft bearings every five years or during major machinery service intervals. Regular monitoring helps detect early signs of wear, preventing unexpected failures and ensuring continued reliability in operation.Q: Where can customized intermediate shaft bearings be sourced?

A: Customized intermediate shaft bearings are available through our export and supply services across India. We cater to manufacturers, service providers, suppliers, and traders, ensuring custom fitment and precision for various heavy machinery applications.Q: What advantages does rebabbitted bearing lining offer?

A: Rebabbitted bearing lining significantly enhances wear resistance, load capacity, and corrosion protection. The combination of steel body with high-grade white metal ensures superior operational reliability, especially under demanding temperature and speed conditions.Q: How are repaired bearings inspected for structural integrity?

A: All repaired bearings undergo ultrasonic and dye penetrant testing. These advanced inspection methods verify alignment, detect hidden flaws, and ensure that the bearing meets rigorous quality and safety standards before installation.Q: What are the benefits of split housing and custom fitment?

A: Split housing allows for easy installation and removal, reducing machinery downtime and maintenance effort. Custom fitment ensures every bearing matches the exact shaft dimensions, supporting reliable operation and extended service life.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in White Metal Bearing Category

White Metal Engine bearing

Price 3200 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Outside Diameter : 72 mm

Lubrication Type : Other, Oil Lubrication

Number Of Rows : Single Row

Bearing Type : Other, White Metal Engine Bearing

Trimetal Bearing

Price 3100 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Outside Diameter : 70 mm

Lubrication Type : Other, Oil

Number Of Rows : Single Row

Bearing Type : Other, Trimetal Bearing

Rebabbitting of White Metal Bearings Manufacturer For 43 Years

Price 16000 USD ($) / Number

Minimum Order Quantity : 1 Number

Outside Diameter : Upto 1500 mm or as specified

Lubrication Type : Other, Oil or Grease

Number Of Rows : Other, Single and Double Row (as per requirement)

Bearing Type : Other, White Metal / Babbitt Journal Bearing

Babbitt White Metal Mearing Repair

Price 3400 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Outside Diameter : Standard & Customized

Lubrication Type : Other, Oil Lubricated

Number Of Rows : Other, Single

Bearing Type : Other, White Metal/Babbitt Bearing

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS