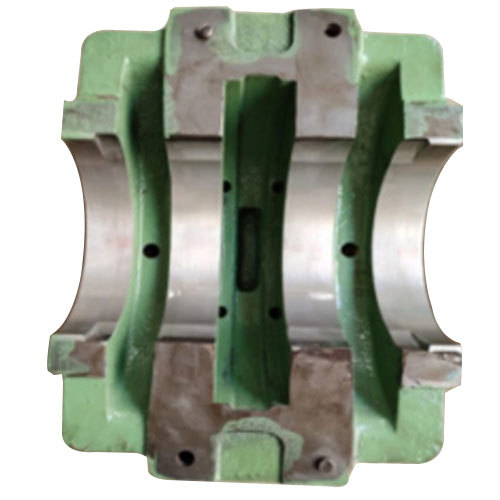

Trimetal Bearing

Price 3100 USD ($)/ Piece

Trimetal Bearing Specification

- Retainer

- Steel

- Lubrication Type

- Oil

- Precision Rating

- P6

- Cage Material

- Steel

- Thickness

- 6 mm

- Inside Diameter

- 35 mm

- Bearing Type

- Trimetal Bearing

- Material

- Steel/Copper/Lead Bronze

- Structure

- Trimetal

- Seals Type

- Open

- Number Of Rows

- Single Row

- Bore Size

- 35 mm

- Outside Diameter

- 70 mm

- Limiting Speed

- 6500 RPM

- Load Capacity

- High

- Shape

- Round

- Corrosion Resistance

- Yes

- Tolerance

- ±0.01 mm

- Application

- Automotive, Industrial Engines, Compressors

- Surface Finish

- Polished

- Packaging Type

- Box

- Feature

- Anti-Friction, Durable

- Hardness

- 60 HRC

- Temperature Range

- -20°C to 200°C

Trimetal Bearing Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 2-3 Days

About Trimetal Bearing

Tri Metal Bearings for crank pin and main journal of all make and model of Diesel engine, Compressor, pumps are available. We have the facility to manufacture Tri metal bearings for different applications as per drawing or a sample provided by the client.

Since we are the leaders in onsite repair of the crankshaft of main and auxiliary engines up to 700mm diameter. We also develop and manufacture a special size and under size Tri metal bearings. The bearing of white metal and Bi metal are also manufactured.

Designed for Demanding Applications

Our Trimetal Bearings are specifically crafted to serve the rigorous requirements of automotive, industrial engines, and compressors. The robust combination of steel, copper, and lead bronze ensures dependable performance, resistance to corrosion, and resilience under heavy loads. Each bearing meets high precision and surface finish standards, resulting in increased efficiency and lifespan in demanding machinery.

Quality and Precision You Can Trust

Every bearing is manufactured under strict quality protocols, boasting a tolerance of 0.01 mm and a hardness of 60 HRC. The polished surface and P6 precision rating facilitate optimal performance even at high speeds up to 6500 RPM. Open seals design and oil lubrication contribute to reduced friction and enhanced durability for long-term use.

FAQ's of Trimetal Bearing:

Q: How is a trimetal bearing utilized in automotive and industrial engines?

A: Trimetal bearings are commonly used to support rotating shafts in automotive and industrial engines, offering excellent load-bearing capacity, low friction, and reliable performance over prolonged use. Their robust construction makes them suitable for high-stress environments with consistent heavy-duty cycles.Q: What is the process for installing a trimetal bearing with a 35 mm bore size?

A: Installation involves ensuring the housing and shaft are clean, checking alignment, applying oil-based lubrication, and carefully fitting the bearing into place. Given its 0.01 mm tolerance, proper installation minimizes wear and guarantees optimal function.Q: When is it recommended to replace a trimetal bearing in compressors or engines?

A: It is best to replace the bearing if you notice unusual noise, increased vibration, or a decline in equipment performance. Regular inspection after heavy usage or as part of scheduled maintenance helps detect early signs of wear or damage.Q: Where can your trimetal bearings be applied besides automotive and compressors?

A: Apart from automotive and compressors, these bearings are suitable for use in heavy-duty industrial machinery, generator sets, and certain types of hydraulic equipment where high loads and precise tolerances are needed.Q: What are the benefits of using a trimetal bearing with a 60 HRC hardness and corrosion resistance?

A: A 60 HRC hardness ensures the bearing is highly wear-resistant and durable, extending service life under tough conditions. Corrosion resistance protects the bearing in harsh or varying environmental conditions, reducing maintenance and downtime.Q: How does the anti-friction, polished surface improve bearing performance?

A: The polished, anti-friction surface reduces mechanical resistance between moving parts, which minimizes heat generation, decreases energy loss, and ultimately leads to smoother operation and longer bearing life.Q: What role does oil lubrication and an open seal type play in the bearing's operation?

A: Oil lubrication ensures continuous reduction of friction and effective heat dissipation, while the open seal type allows for easy inspection and maintenance. Together, these features support sustained high-speed operation and reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in White Metal Bearing Category

Babbitt White Metal Bearing

Price 3300 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Load Capacity : High

Precision Rating : P6

Material : Other, Babbitt White Metal

Lubrication Type : Other, Oil Lubrication

Babbitt Bearing

Price 3500 USD ($) / Piece

Minimum Order Quantity : 1 , , Piece

Load Capacity : Heavy Duty

Precision Rating : General Grade

Material : Other, Babbitt Metal (Lead or Tin Based Alloy)

Lubrication Type : Other, Oil Lubricated

White Metal Bearings

Price 3100 USD ($) / Piece

Minimum Order Quantity : 1 , , Piece

Load Capacity : High radial and thrust load

Precision Rating : Industry Standard / Custom tolerances

Material : Other, White Metal (Babbitt Alloy)

Lubrication Type : Other, Oil Lubricated (Hydrodynamic)

Rebabbitting Of Old Bearing

Price 3200 USD ($) / Piece

Minimum Order Quantity : 1 , , Piece

Load Capacity : Heavy Duty

Precision Rating : ISO Standard

Material : Other, HighQuality White Metal (Babbitt alloy)

Lubrication Type : Other, Oil Lubricated

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS