Rebabbitting Of Old Bearing

Price 3200 USD ($)/ Piece

Rebabbitting Of Old Bearing Specification

- Thickness

- As per standard or old bearing

- Precision Rating

- ISO Standard

- Lubrication Type

- Oil Lubricated

- Inside Diameter

- Custom as per requirement

- Bearing Type

- Journal Bearing (Rebabbitted)

- Material

- High-Quality White Metal (Babbitt alloy)

- Structure

- Split Type

- Number Of Rows

- Single

- Bore Size

- Custom as per old bearing

- Outside Diameter

- Custom as per old bearing

- Limiting Speed

- Depends on lubrication

- Load Capacity

- Heavy Duty

Rebabbitting Of Old Bearing Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 1 , , Piece Per Day

- Delivery Time

- 2-3 Days

- Certifications

- ISO 9001:2015 SEPC

About Rebabbitting Of Old Bearing

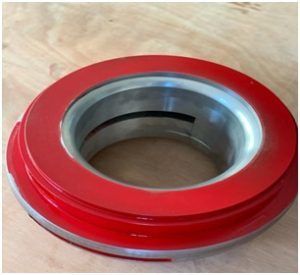

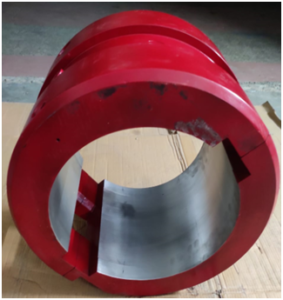

Rebabbitting Of Old Bearing

We at RA Power Solutions believe that rebabbitting of old damaged bearings is more complexed than manufacturing of new white metal bearings. For repair of Babbitt bearings, various quality control checks are necessary prior to undertaking of Rebabbitting of white metal.

Precision Rebabbitting for Heavy Duty Applications

Our rebabbitting service ensures that worn bearings are restored to like-new condition with excellent load capacity and reliability in demanding industrial settings. With customizable options for bore size, outside diameter, and thickness, the finished bearings meet or exceed OEM and ISO standards, prolonging the life of critical machinery.

Stringent Quality and Testing Processes

Each bearing undergoes a comprehensive process that includes full removal of old white metal, recasting with certified Babbitt alloys, and precise machining. Post-processing utilizes ultrasonic crack detection and dimensional verification, ensuring defect-free bearings that fit perfectly and withstand heavy operational loads.

FAQ's of Rebabbitting Of Old Bearing:

Q: How is the rebabbitting process for old bearings carried out?

A: The rebabbitting process involves removing the worn white metal layer from the old bearing, cleaning and preparing the base, then re-casting the surface with high-quality Babbitt alloy. After cooling, the bearing is machined to precise dimensions, followed by ultrasonic crack testing and thorough dimensional checks.Q: What types of machinery or industries can benefit from rebabbitted bearings?

A: Rebabbitted bearings are suitable for heavy machinery and industrial equipment across industries such as power generation, steel mills, cement plants, and more, especially where heavy-duty journal bearings are used and prolonged operational life is essential.Q: When should I consider rebabbitting my existing bearings instead of replacement?

A: Rebabbitting is recommended when the original bearing shell remains structurally sound but the inner white metal surface shows wear, scoring, or minor damage. It is a cost-effective solution that restores functionality without needing a complete replacement, minimizing downtime and extending equipment life.Q: Where is your rebabbitting service available?

A: We provide rebabbitting and restoration services throughout India, serving as exporters, manufacturers, service providers, suppliers, and traders for major industries and OEMs nationwide.Q: What are the advantages of rebabbitting over installing new bearings?

A: Rebabbitting is often more economical, especially for large or rare bearings, as it allows custom refurbishment to specific machinery requirements, preserves the original housing, and reduces lead time compared to manufacturing brand-new bearings from scratch.Q: How do you ensure the quality and reliability of rebabbitted bearings?

A: Every rebabbitted bearing undergoes ultrasonic crack testing for hidden flaws and detailed dimensional verification to meet OEM or customized specifications. We use certified Babbitt alloys and adhere to ISO precision ratings, ensuring reliable, long-lasting performance.Q: Can bearings of any size and make be rebabbitted?

A: Yes, our services are fully customizable to accommodate any bore size, outside diameter, structure (split type), and number of rows, as per the requirements of the old bearing or customer specifications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in White Metal Bearing Category

White Metal Engine bearing

Price 3200 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Thickness : 11 mm

Outside Diameter : 72 mm

Load Capacity : High

Structure : Plain Bearing

White Metal Bearings

Price 3100 USD ($) / Piece

Minimum Order Quantity : 1 , , Piece

Thickness : Varies as per design

Outside Diameter : Customized as per application

Load Capacity : High radial and thrust load

Structure : Split / Solid (as per requirement)

Babbitt White Metal Mearing Repair

Price 3400 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Thickness : As per Specification

Outside Diameter : Standard & Customized

Load Capacity : High

Structure : Solid

Babbitt White Metal Ingots

Price 3300-70000 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Thickness : Varies

Outside Diameter : Customizable

Load Capacity : High

Structure : Solid Ingot

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS