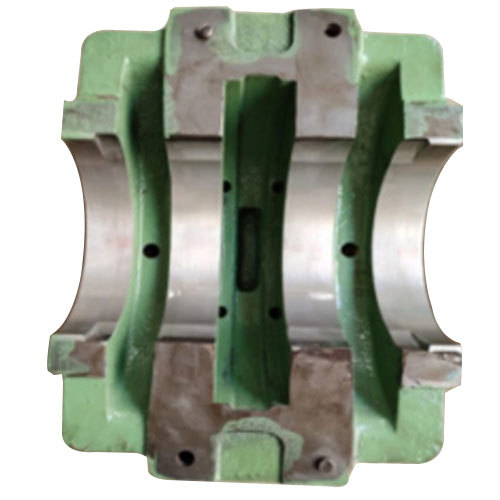

White Metal Bearings

Price 3100 USD ($)/ Piece

White Metal Bearings Specification

- Lubrication Type

- Oil Lubricated (Hydrodynamic)

- Cage Material

- Generally Not Required

- Precision Rating

- Industry Standard / Custom tolerances

- Inside Diameter

- Customized per shaft size

- Thickness

- Varies as per design

- Bearing Type

- White Metal Journal Bearing

- Material

- White Metal (Babbitt Alloy)

- Structure

- Split / Solid (as per requirement)

- Seals Type

- Open / with end covers or seals

- Number Of Rows

- Single or Multi-Row

- Bore Size

- Custom as per design

- Outside Diameter

- Customized as per application

- Limiting Speed

- Standard to moderate, depends on lubrication

- Load Capacity

- High radial and thrust load

- Shape

- Cylindrical/Split/Flanged/Custom

- Conformability

- Excellent absorbs minor shaft misalignments

- Hardness

- Soft Metal Surface for embedability

- Mounting

- Horizontal or Vertical

- Finish

- Machined, Ground or Scrapped

- Core Material

- Steel, Bronze or Cast Iron Backing

- Standard

- IS, BS, or Customer-Specific

- Feature

- Removable, Replaceable Liner (if required)

- Application

- Turbines, Generators, Compressors, Pumps, Gearboxes, Marine Engines

- Temperature Range

- Up to 150C (302F), depends on alloy

White Metal Bearings Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 1 , , Piece Per Day

- Delivery Time

- 2-3 Days

- Certifications

- ISO 9001:2015 SEPC

About White Metal Bearings

White Metal Bearings

RA Power Solution manufactures thin shell tri metal bearings, bi metal or white metal babbitt bearings. It is observed that thin shell tri metal bearings are most common bearings used in diesel engines. The main material composition for bearings is steel-babbitt, steel-bronze and steel-tin. The tin based bearing has the property of higher load bearing capacity in comparison to other bearings.

Precision Engineering for Demanding Applications

Our white metal bearings are designed to stand up to rigorous conditions in turbines, generators, compressors, pumps, gearboxes, and marine engines. With a customizable structure and finish, each bearing ensures superior performance, reliability, and longevity even in high-load scenarios.

Custom-Built for Versatility and Flexibility

Choose from single or multi-row, split or solid, and custom bore & diameter options to perfectly fit your machinery. Horizontal or vertical mounting and a selection of core materials make these bearings easily adaptable for a variety of industrial requirements.

Consistent Performance and Easy Maintenance

The unique removable or replaceable liner feature simplifies service and minimises downtime, while hydrodynamic oil lubrication enhances limiting speed capacity. Their extraordinary conformability absorbs shaft misalignments for greater protection and durability.

FAQs of White Metal Bearings:

Q: How are white metal bearings finished for industrial use?

A: White metal bearings can be finished by machining, grinding, or scrapping. These processes meet industry standards such as IS or BS or can be tailored to customer-specific requirements to ensure optimal fit and performance in varied applications.Q: What is the typical application range of these bearings?

A: These bearings are designed for installation in turbines, generators, compressors, pumps, gearboxes, and marine engines. Their high load capacity and temperature tolerance enable safe operation in demanding environments.Q: Where are white metal bearings manufactured and supplied from?

A: Our white metal bearings are produced, exported, and supplied across India by experienced manufacturers, exporters, service providers, and traders, supporting both domestic and international customers.Q: What is the process for replacing or maintaining the liner in these bearings?

A: The bearings feature a removable or replaceable liner, allowing for easy maintenance. Depending on the design and accessibility, liners can be exchanged without dismounting the bearing housing, minimizing machine downtime and service effort.Q: Why is a soft metal surface advantageous in these bearings?

A: The soft metal surface enhances embedability and conformability, absorbing minor shaft misalignments and foreign particles, thereby protecting machinery and extending operational life.Q: What are the benefits of choosing customized bore size and outside diameter?

A: Selecting custom bore size and outside diameter allows for precise alignment with shaft specifications, maximizes load distribution, and ensures seamless integration into your equipments design.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in White Metal Bearing Category

Trimetal Bearing

Price 3100 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Lubrication Type : Other, Oil

Bearing Type : Other, Trimetal Bearing

Precision Rating : P6

Structure : Trimetal

Babbitt White Metal Bearing

Price 3300 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Lubrication Type : Other, Oil Lubrication

Bearing Type : Other, Journal Bearing

Precision Rating : P6

Structure : Split

Babbitt Bearing

Price 3500 USD ($) / Piece

Minimum Order Quantity : 1 , , Piece

Lubrication Type : Other, Oil Lubricated

Bearing Type : Other, Babbitt Bearing

Precision Rating : General Grade

Structure : Solid Housing

Rebabbitting of White Metal Bearings Manufacturer For 43 Years

Price 16000 USD ($) / Number

Minimum Order Quantity : 1 Number

Lubrication Type : Other, Oil or Grease

Bearing Type : Other, White Metal / Babbitt Journal Bearing

Precision Rating : Up to ISO or DIN Standard

Structure : White Metal Bearing

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free