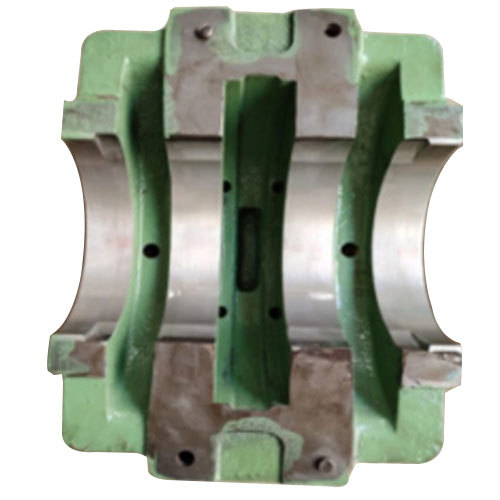

Babbitt Bearing

Price 3500 USD ($)/ Piece

Babbitt Bearing Specification

- Lubrication Type

- Oil Lubricated

- Retainer

- Solid

- Inside Diameter

- Customizable as per requirement

- Thickness

- Varies as per dimension

- Precision Rating

- General Grade

- Bearing Type

- Babbitt Bearing

- Material

- Babbitt Metal (Lead or Tin Based Alloy)

- Structure

- Solid Housing

- Seals Type

- No Seals (Open)

- Number Of Rows

- Single Row

- Bore Size

- Customizable as per requirement

- Outside Diameter

- Customizable as per requirement

- Limiting Speed

- Moderate to Low

- Load Capacity

- Heavy Duty

Babbitt Bearing Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 1 , , Piece Per Day

- Delivery Time

- 2-3 Days

- Certifications

- ISO 9001:2015 SEPC

About Babbitt Bearing

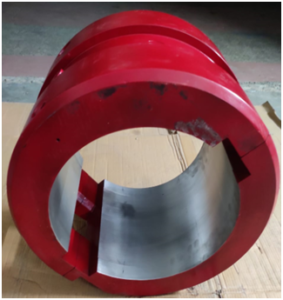

- White metal from the old bearing is removed in a controlled temperature.

- Metallurgical test of existing Babbitt white metal is undertaken.

- The steel shell of the old white metal Babbitt bearing is shot blasted.

- Surface hardness is checked for presence of any hardspots.

- Crack detection by MPI and dye-penetrant test is done.

- After Rebabbitting process, above inspection procedure is repeated.

- Ultrasound of white metal Babbitt bearing after repairs is of great importance to check the bonding.

Versatile Solution for Heavy Machinery

Babbitt bearings are widely used across heavy machinery, including engines, turbines, compressors, and pumps. Their adaptability suits varied industrial environments, with options for both half and full shell designs, ensuring compatibility with different housing setups. The solid construction and customizable dimensions make them ideal for high-stress and heavy-duty operations.

Superior Performance and Durability

Machined and polished to exacting standards, Babbitt bearings deliver excellent conformability and embeddability, which help maintain smooth operation under demanding conditions. These bearings resist corrosion and accommodate both interference and shrink fit installation methods, providing long-lasting reliability with moderate to low-speed capacities.

FAQs of Babbitt Bearing:

Q: How are Babbitt bearings installed in heavy machinery?

A: Babbitt bearings are typically installed using interference fit or shrink fit methods. These installation processes ensure the bearings are securely seated within the housing, optimizing load distribution and alignment in engines, pumps, turbines, and compressors.Q: What types of equipment commonly use Babbitt bearings?

A: Babbitt bearings are employed in heavy-duty equipment such as industrial engines, turbines, compressors, and pumps. Their robust design and high load capacity make them suitable for demanding applications in these sectors.Q: When should I choose a Babbitt bearing with a half shell or full shell design?

A: The selection between half shell and full shell Babbitt bearings depends on the machines housing configuration and maintenance requirements. Full shells provide comprehensive support, while half shells offer easier installation and replacement in certain applications.Q: Where are Babbitt bearings typically manufactured and supplied?

A: Babbitt bearings are manufactured and exported by reputable suppliers, manufacturers, and service providers in India, serving global markets for industrial machinery and equipment components.Q: What benefits do Babbitt bearings offer in terms of operational performance?

A: Babbitt bearings provide excellent conformability and embeddability, good corrosion resistance, and are designed to handle heavy loads. They help machine components run smoothly, reducing wear and accommodating minor misalignments.Q: How does the lubrication process work for Babbitt bearings?

A: Babbitt bearings are oil lubricated, which helps reduce friction and extend bearing life. Regular maintenance ensures the lubrication remains effective, contributing to the overall performance and reliability of the machinery.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in White Metal Bearing Category

Babbitt White Metal Mearing Repair

Price 3400 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Inside Diameter : Custom

Bore Size : Custom

Load Capacity : High

Lubrication Type : Other, Oil Lubricated

White Metal Bearings

Price 3100 USD ($) / Piece

Minimum Order Quantity : 1 , , Piece

Inside Diameter : Customized per shaft size

Bore Size : Custom as per design

Load Capacity : High radial and thrust load

Lubrication Type : Other, Oil Lubricated (Hydrodynamic)

Babbitt White Metal Alloy Manufacturer

Price 3500 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Inside Diameter : Custom

Bore Size : Custom

Load Capacity : High

Lubrication Type : Other, Oil Lubricated

Babbitt White Metal Bearing Manufacturer

Price 1600 USD ($) / Number

Minimum Order Quantity : 1 Number

Inside Diameter : More than 250 mm Millimeter (mm)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS