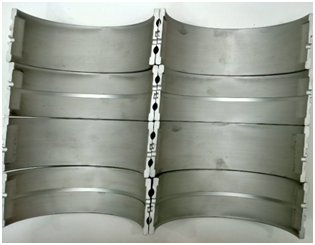

Tri Metal Bearing

Price 1500 USD ($)/ Number

Tri Metal Bearing Specification

- Thickness

- 15 mm

- Cage Material

- Steel

- Lubrication Type

- Oil Lubrication

- Inside Diameter

- 30 mm

- Retainer

- Steel

- Precision Rating

- P5

- Bearing Type

- Plain Bearing

- Material

- Copper-Lead Alloy with Babbit Layer

- Structure

- Tri Metal

- Seals Type

- Open

- Number Of Rows

- Single Row

- Bore Size

- 30 mm

- Outside Diameter

- 52 mm

- Limiting Speed

- Up to 7000 rpm

- Load Capacity

- High

Tri Metal Bearing Trade Information

- Minimum Order Quantity

- 1 , , Number

- Supply Ability

- 1 , , Number Per Day

- Delivery Time

- 2-3 Days

About Tri Metal Bearing

We are the manufacturer and traders for Tri metal and Bi metal Bearings used in Diesel engine, Compressor & all type of Rotating equipment.

As a Marine engine and mechanical equipment repair company serving the industries & shipping companies all over the world for the last 41 years we understand the importance of availability of not only the high quality of Tri metal and Bi metal Bearing but the importance of delivery of bearings on time. During our experience of the last four decades we have observed that although the crankshaft of the marine engine, compressor or any rotating equipment is repaired but due to non availability of the crank pin & main journal bearing engine cannot be put back into operation thus causing losses to the owner.

The non availability of engine & compressor bearing may be because the equipment is outdated and no more manufactured by the original equipment manufacturer.

There are number of marine engine, diesel generating sets, compressors in operation on vessels or industries the manufacturing of which has been discontinued due to either closure of the manufacturing unit or the equipment has become absolute.

RA Power Solutions plays an important role in manufacturing of marine engine, diesel generator, compressor and Rotating equipment bearing of Tri metal and Bi metal.

Tri metal Bearing & Bi metal Bearing manufacturer

We have the Principles based in UK, Europe, Japan from where we source the Tri Metal Bearing, The Bi metal Bearings and babbitt white metal Bearing up to 1500 mm diameter are manufactured in house.

In case your Engine model is old and is no more manufactured by the manufacturer, RA Power Solutions can help you in development & manufacturing of Tri metal/ Bi metal bearing strictly as per the drawing provided by you.

We also develop and manufacture Tri metal & Bi metal Bearing as per the sample provided by the client.

Manufacturing of standard and non standard Tri metal and Bimetal Bearing for marine engine and compressor

As a crankshaft repair company we have observed that due to serious accidents the damage to the crank pin/ main journal is much more than the last limit of under size recommended by the manufacturer. In this case the engine manufacturer refuses to supply the under size and oversize bearing.

For example, in case of the last limit of Daihatsu crank pin having a standard diameter of 170 mm and after grinding the size obtained is 167 mm, we manufacture the bearing of 3.0 mm under size and put the engine back into operation on other hand as per the manufacturer of the engine, crankshaft cannot be used and is rejected.

We have saved hundreds of crankshaft by supplying under size Tri metal Bearing/ Bi metal Bearing beyond the last limit of grinding recommended by the engine manufacturer.

We regularly supply Tri metal Bearing/ Bi metal Bearing for all make & model of engines like Wartsila, MAK, MAN B&W, Yanmar, Daihatsu, Himsen, Caterpillar, Bergen, Deutz etc.

We have been regularly exporting the bearings to Bahrain, Bangladesh, Bhutan, Brunei, Burma, Cambodia, East Timor, Georgia, Hong Kong, India, Indonesia, Iran, Iraq, Israel, Japan, Jordan, Kazakhstan, Kuwait, Kyrgyzstan, Laos, Lebanon, Malaysia, Mongolia, Nepal, North Korea, Oman, Papua New Guinea, Philippines, Qatar etc.

Precision Engineering for Reliability

Our Tri Metal Bearings are meticulously manufactured using copper-lead alloy and a Babbit layer to ensure exceptional strength and longevity. Precision ground surfaces and steel cages provide outstanding durability, supporting high-speed operations and heavy loads for various industrial and automotive applications.

Superior Performance in Harsh Environments

With a temperature endurance from -20C to 150C and high corrosion resistance, these bearings operate efficiently in challenging conditions, minimizing wear and maintaining consistent function. Excellent conformability and low friction minimize energy loss and noise, enhancing overall operational performance.

FAQ's of Tri Metal Bearing:

Q: How is the Tri Metal Bearing beneficial for automotive engines and heavy machinery?

A: The Tri Metal Bearing is designed to support high loads and withstand the rigorous operating conditions found in automotive engines and heavy machinery. Its high hardness, conformability, and low friction coefficient result in enhanced durability and low maintenance requirements, ensuring reliable performance over extended periods.Q: What materials are used in the construction of this bearing, and what advantages do they offer?

A: This bearing is manufactured with a copper-lead alloy base and a Babbit layer. The copper-lead alloy provides excellent strength and wear resistance, while the Babbit layer offers superior conformability and low friction, resulting in reduced noise and efficient operation.Q: When should Tri Metal Bearings be used over other types of bearings?

A: Tri Metal Bearings are recommended when the application demands high load capacity, longevity, and resistance to harsh environments, such as in compressors, automotive engines, and heavy machinery. Their ability to perform under high speeds and varying temperatures makes them preferable over simpler bearing designs.Q: Where are these bearings typically installed, and what industries benefit most from their use?

A: They are commonly found in industrial settings within automotive manufacturing, heavy machinery operation, and compressor assemblies. Industries requiring reliable, high-performance, and low-noise plain bearings particularly benefit from this product's advanced features.Q: What is the process for maintaining and lubricating Tri Metal Bearings for optimal performance?

A: Maintenance involves regular inspection for wear and adequate lubrication using oil, as specified for this bearing type. Proper lubrication reduces friction and prolongs service life, while precision ground surfaces make routine servicing straightforward and efficient.Q: How does compliance with ISO 3547 Standards impact bearing quality?

A: Compliance with ISO 3547 standards guarantees that the bearing meets stringent international requirements for dimensional accuracy, material quality, and operational reliability, ensuring consistent performance and safety for end-users.Q: What are the main usage benefits offered by the Tri Metal Bearing's low noise and high corrosion resistance features?

A: Low noise operation results in quieter machinery environments, enhancing comfort and productivity. High corrosion resistance extends bearing life, reduces downtime for maintenance, and enhances reliability in humid or chemically aggressive settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in White Metal Bearing Category

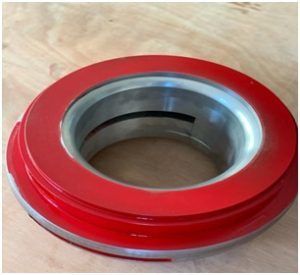

White Metal Engine bearing

Price 3200 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Bearing Type : Other, White Metal Engine Bearing

Precision Rating : ISO Grade 7

Structure : Plain Bearing

Outside Diameter : 72 mm

Babbitt Bearing

Price 3500 USD ($) / Piece

Minimum Order Quantity : 1 , , Piece

Bearing Type : Other, Babbitt Bearing

Precision Rating : General Grade

Structure : Solid Housing

Outside Diameter : Customizable as per requirement

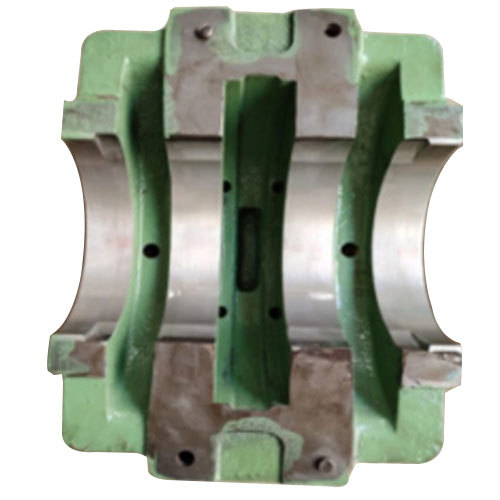

Intermediate Shaft Repair and Rebabbitting of Intermediate Shaft Bearing

Price 6000.0 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Bearing Type : Other, Intermediate Shaft Bearing

Precision Rating : ISO standard

Structure : Split Cylindrical

Outside Diameter : Custom sizes on request

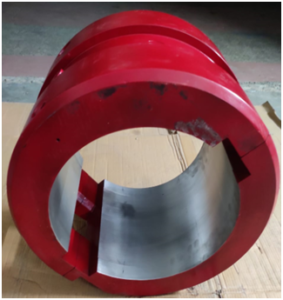

Babbitt White Metal Mearing Repair

Price 3400 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Bearing Type : Other, White Metal/Babbitt Bearing

Precision Rating : ISO 9001:2015

Structure : Solid

Outside Diameter : Standard & Customized

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS