Metal Stitching Of Crack Casting

Price 1500 INR/ Square Inch

Metal Stitching Of Crack Casting Trade Information

- Minimum Order Quantity

- 1 Square Inch

- Supply Ability

- 1 Square Inch Per Day

- Delivery Time

- 2-3 Days

- Certifications

- ISO 9001:2015 SEPC

About Metal Stitching Of Crack Casting

Metal Stitching Of Crack Casting

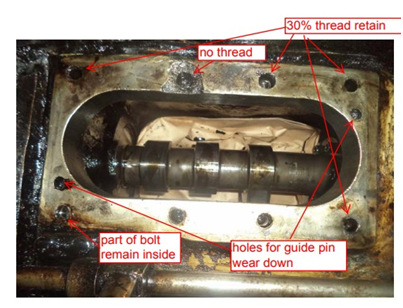

Cast iron components develop cracks and break into pieces as a result of accident or overload. The replacement of crack component is expensive. It is recommended to repair crack and broken casting by metal stitching and metal locking process.

RA Power Solutions undertakes repair of crack engine block, cylinder heads and cast components onsite by metal stitching and metal locking process which is proved to be successful.

We also stand guarantee for the satisfactory performance after metal stitching/metal locking of the component.

Contact us for more information.

Restoring Cast Components with Metal Stitching

Metal stitching-also known as metal locking-is a proven technique for repairing cracked or broken cast iron, steel, and aluminum alloy parts. This cold process avoids the risks of welding, delivers a corrosion-resistant, leak-proof finish, and ensures minimal downtime. We conform to the highest industry standards while providing on-site service and tailored finishing.

Superior Strength, Precision, and Corrosion Resistance

Our metal stitching process restores the original strength of cast components, using high-quality alloy steel pins and precise equipment. We guarantee high corrosion resistance and maintain the dimensional accuracy of even complex parts. Every repair is crafted to meet both safety and performance standards, achieving a reliable, long-lasting result.

FAQ's of Metal Stitching Of Crack Casting:

Q: How does metal stitching repair cracks without using heat?

A: Metal stitching employs a cold repair process where specially designed alloy steel pins are inserted along the crack, locking the sections together. This method restores strength and prevents heat-affected zones, avoiding thermal distortion and maintaining the original material properties.Q: What types of cracks can be repaired through metal stitching of castings?

A: This method addresses various crack types, including longitudinal, transverse, stress, shrinkage, and mechanical cracks. It is suitable for cast iron, cast steel, and aluminum alloy components such as engine blocks, cylinder heads, machine frames, and housings.Q: When is metal stitching preferred over welding for casting repairs?

A: Metal stitching is ideal when the component must retain its original structure and properties, as it introduces no heat and therefore eliminates the risk of weakening or warping the base material-a common issue with welding, especially for cast iron or precision machinery parts.Q: Where can metal stitching services be performed?

A: Our technicians provide on-site metal stitching services across India, allowing repairs without dismantling or transporting bulky equipment, thereby drastically reducing downtime and logistical overhead.Q: What benefits does metal stitching offer in terms of operational downtime?

A: Because metal stitching is carried out on-site and does not require prolonged cooling or post-repair heat treatment, it significantly minimizes operational downtime, enabling faster return to service for essential equipment.Q: How is the finish quality ensured after a metal stitching repair?

A: Depending on requirements, the repaired area can be machined to precise tolerances or hand-finished. We use high-precision tools to maintain both functionality and appearance, while ensuring the repair remains leak-proof and structurally sound.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Metal Stitching Category

Aluminium Piston Crack Repair

Price Range 160000.00 - 1300000.00 INR / Square Inch

Minimum Order Quantity : 1 , , Square Inch

Cast Iron Crack Repair

Price Range 160000.00 - 900000.00 INR / Square Inch

Minimum Order Quantity : 1 , , Square Inch

Metal Stitching & Metal Locking of Engine Block

Price 1500 INR / Square Inch

Minimum Order Quantity : 1 , , Square Inch

Metal Stitching of Engine Block

Price Range 300000.00 - 8900000.00 INR / Square Inch

Minimum Order Quantity : 1 , , Square Inch

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS