Cast Iron Crack Repair

Cast Iron Crack Repair Trade Information

- Minimum Order Quantity

- 1 , , Square Inch

- Supply Ability

- 1 , , Square Inch Per Day

- Delivery Time

- 2-3 Days

About Cast Iron Crack Repair

We undertake Cast iron crack repair by metal locking, metal stitching, and metal surgery process. The repair of cracks by metal lock and metal stitching is a successful method of repairing cracks in cast iron, aluminium and bronze alloy. The metal stitching method is a cold process as no heat is generated like in the welding process. We have the facility for offering on-site metal stitching and metal surgery services even while the vessel is on move.

High-Temperature and Chemical Resistance

Engineered to tolerate extreme heat up to 600C and deliver outstanding chemical resistance, Cast Iron Crack Repair is ideal for applications exposed to elevated temperatures and aggressive fluids like oils and coolants. Its formulation ensures component longevity and reliability in challenging industrial environments.

User-Friendly Application & Quick Curing

This product requires only manual tools-spatula or applicator-for seamless application. It creates a smooth surface finish, making it suitable for aesthetic and functional restoration. With a curing time of just 4-6 hours, repairs can be completed efficiently, minimizing downtime for critical machinery.

Safe Storage & Long Shelf Life

Cast Iron Crack Repair comes in tube or container packaging, ensuring convenient storage and use. It boasts a 12-month shelf life when kept in a cool, dry place, making it a dependable choice for ongoing maintenance and emergency repairs in industrial settings.

FAQ's of Cast Iron Crack Repair:

Q: How should Cast Iron Crack Repair be properly applied to a cracked component?

A: Clean and dry the crack thoroughly before applying the product. Using a spatula or applicator, spread the compound over and into the crack, ensuring a smooth finish. Allow the repair to cure undisturbed for 4-6 hours for the best results.Q: What types of cast iron parts and machinery can be repaired with this solution?

A: This cold welding solution is suitable for repairing cracks in engine blocks, chassis parts, gearboxes, manifolds, water pumps, valves, brackets, and various housings made of cast iron.Q: When is the repaired component ready to be put back into service after using the product?

A: After application, allow the product to cure for 4-6 hours. Once fully cured, the component can be returned to its operational environment, even under high temperature and exposure to oils or coolants.Q: Where should Cast Iron Crack Repair be stored to maintain its effectiveness?

A: Store the product in a cool, dry location away from direct sunlight and moisture. Proper storage helps maintain its performance and extends its shelf life up to 12 months.Q: What are the advantages of using this cast iron repair solution over traditional welding methods?

A: Unlike traditional welding, this cold welding compound requires no specialized equipment or heat and eliminates the risk of thermal distortion. It allows for quick, strong repairs with a smooth finish, making it convenient and effective for on-site maintenance.Q: What safety measures should be followed during the repair process?

A: Always wear gloves and ensure the area is well-ventilated when handling and applying the product. This helps protect against skin contact and inhalation of any fumes during use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Metal Stitching Category

Aluminium Piston Crack Repair

Price Range 160000.00 - 1300000.00 INR / Square Inch

Minimum Order Quantity : 1 , , Square Inch

Metal Stitching of Engine Block

Price Range 300000.00 - 8900000.00 INR / Square Inch

Minimum Order Quantity : 1 , , Square Inch

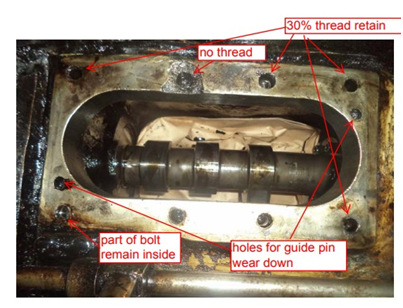

Cylinder Liner/ Engine Block/ Crack Repair of MAN Main Engine/ Metal Lock and Metal Stitching

Price 122018 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Crack Repair Of Aluminium Bronze and Cast Iron component By Metal Lock and Metal Stitching

Price 1600 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS