Yanmar Diesel Generator Model no. 8N280L-EV Crankshaft Repair

Price 1500 INR/ Square Inch

Yanmar Diesel Generator Model no. 8N280L-EV Crankshaft Repair Specification

- Material

- Forged Steel

- Cooling Method

- Water Cooled

- Packaging Type

- Wooden Box

- Number of Cylinders Supported

- 8

- Repair Service

- Crankshaft Repair

- Product Type

- Diesel Generator Crankshaft

- Suitable For

- Marine and Industrial Applications

- Usage

- Generator Engine

- Max RPM

- 750

- Surface Treatment

- Precision Machined and Polished

- Model Number

- 8N280L-EV

Yanmar Diesel Generator Model no. 8N280L-EV Crankshaft Repair Trade Information

- Minimum Order Quantity

- 1 Square Inch

- Supply Ability

- 1 Square Inch Per Day

- Delivery Time

- 2-3 Days

About Yanmar Diesel Generator Model no. 8N280L-EV Crankshaft Repair

RA Power Solutions was approached by one of largest shipping company based in Athens Greece regarding breakdown of Crankshaft of YANMAR Diesel Generator Model no. 8N280L-EV. The vessel was to take a berth at Mundra port India and the stay of the vessel at port was limited to only 13 hrs.

Following is the details of the crankshaft of Yanmar Diesel Generator Model no. 8N280L-EV

|

Crankshaft Details |

|

|

|

1 |

Engine Make |

YANMAR Diesel Generator |

|

2 |

Engine Model |

Model no. 8N280L-EV |

|

3 |

Crankpin Diameter Standard |

225 mm |

|

4 |

Crankpin Bearing Width |

93 mm |

Action taken by RA Power Solutions for successful repair of Crankshaft of Yanmar Diesel Generator Model no. 8N280L-EV.

i) As mentioned above we were given only 13 hrs of time at Mundra Port India to inspect the crankshaft and to execute the repair. In this situation we decided to depute a team of three technicians onboard the vessel instead of two technicians which is our normal practice.

Following are the main observation:

Action taken by RA Power Solutions for successful repair of Crankshaft of Yanmar Diesel Generator Model no. 8N280L-EV.

i) As mentioned above we were given only 13 hrs of time at Mundra Port India to inspect the crankshaft and to execute the repair. In this situation we decided to depute a team of three technicians onboard the vessel instead of two technicians which is our normal practice.

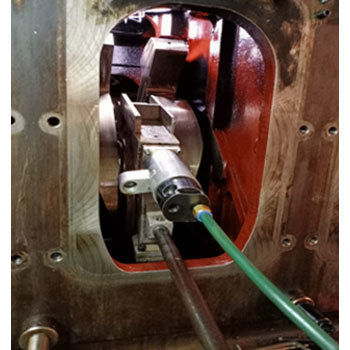

ii) After boarding of the vessel the detailed inspection of crankpin no. 4 which got damaged was conducted.

Following are the main observation:

a) The diameter of crankpin no 4 was checked and following dimensions were observed:

i) Minimum diameter observed - 224.15 mm

ii) Maximum diameter observed - 225.00 mm

Above shows the ovality of 0.85 mm.

b) The crankpin no. 4 was subject to hardness check and was found within limits except on few scattered points where it was observed in the range of 500 HB.

c) The crankpin was subject to crack detection by high intensity magnaflux torch and no cracks or abnormally was observed.

d) Due to the seizure of crankpin bearing the radius fillet of both the sides was badly damaged.

Successful Repair of Crankshaft of Yanmar Diesel Generator Model no. 8N280L-EV in a short time of 13 hrs.

a) Our technicians worked non stop and were able to successfully repair the crankpin no. 4 by undersizing and grinding it to 1.0 mm.

b) After grinding & polishing following minimum & maximum crank pin diameter was maintained:

i) Minimum diameter observed - 223.98 mm

ii) Maximum diameter observed - 224.00 mm

c) The above reading shows the crankpin was undersized by 1.0 mm from 225.00 mm to 224.00 mm thus maintaining the ovality of only 0.02 mm which is far superior than the tolerance stipulated in the manufacturer manual.

d) The formation of radius fillet at both ends was a big challenge as it was badly damaged and time available was limited. The radius fillet was also repaired successfully.

e) The 1.0 m undersize crank pin bearing was available on board the vessel.

f) RA Power Solutions technicians also helped the ship technical staff in calibration of connecting rod, measurement of big end bearing and other areas.

g) It is normal for RA Power Solutions to take such challenging jobs where the damage to the crankshaft due to an accident is very serious and time available is short.

Expert Crankshaft Repair Services

Our crankshaft repair service for the Yanmar 8N280L-EV model utilizes advanced machining techniques to restore your diesel generator's performance. Experienced technicians repair and refinish crankshafts with precision and attention to detail, ensuring optimal functionality for marine and industrial applications. With specialized tools and processes, every repair meets stringent quality standards.

Engineered for Durability and Efficiency

Constructed from premium forged steel, the 8N280L-EV crankshaft is designed to withstand demanding operating environments. Precision machining and polished surface treatment enhance reliability and reduce friction, resulting in extended service life and consistent performance in generator engines. This crankshaft supports water-cooled systems and up to 8 cylinders, making it suitable for extensive usage.

FAQ's of Yanmar Diesel Generator Model no. 8N280L-EV Crankshaft Repair:

Q: How is the crankshaft for the Yanmar 8N280L-EV generator repaired?

A: The repair process involves thorough inspection, advanced precision machining, and surface polishing to restore the crankshaft to its original specifications. Specialized equipment ensures any wear or damage is meticulously addressed, delivering a reliable and high-performing component.Q: What type of applications is the 8N280L-EV crankshaft suitable for?

A: This crankshaft is specifically designed for use in marine and industrial generator engines, supporting up to 8 cylinders and suitable for both replacement and repair in rigorous operating environments.Q: When should I consider crankshaft repair for my diesel generator?

A: Crankshaft repair is recommended when there are signs of wear, vibration, power loss, or abnormal engine sounds. Timely intervention helps prevent costly engine failures and extends the generator's lifespan.Q: Where can your crankshaft repair services be accessed in India?

A: Our services are available across India, catering to clients as exporters, manufacturers, service providers, suppliers, and traders. We offer support through comprehensive logistics to ensure seamless repair and delivery.Q: What are the benefits of choosing a precision machined and polished crankshaft?

A: A precision machined and polished crankshaft minimizes friction, enhances engine efficiency, and ensures smoother operation. These treatments contribute to longer component life and improved generator reliability.Q: Can the crankshaft be used with water-cooled generator engines?

A: Yes, the 8N280L-EV crankshaft is engineered for water-cooled generator engines, enabling efficient thermal regulation and supporting optimal performance in both marine and industrial sectors.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Crankshaft Repair Category

Naval STORK Werkspoor S.A Engine Repair in Haiti

Price 1 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Daihatsu 5DK-20 Engine Crankshaft Repair

Price 1500 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS