Crankshaft Repair Engine MAN 5L 16/24

Price 16000 USD ($)/ Square Inch

Crankshaft Repair Engine MAN 5L 16/24 Specification

- Manufacturing Technique

- Forged

- Surface Treatment

- Polished

- Corrosion Resistance

- Yes

- Condition

- Reconditioned / Repaired

- Type

- Crankshaft Repair Engine

- Usage/Application

- Marine and Industrial Engines

- Quality Standard

- OEM specifications

- Packaging Type

- Custom Crate

- Finish

- Smooth

- Engine Type

- 5-cylinder Inline Diesel

- Model

- MAN 5L 16/24

- Material

- Alloy Steel

- Precision

- High tolerance machining

Crankshaft Repair Engine MAN 5L 16/24 Trade Information

- Minimum Order Quantity

- 1 Square Inch

- Supply Ability

- 1 Square Inch Per Day

- Delivery Time

- 2-3 Days

About Crankshaft Repair Engine MAN 5L 16/24

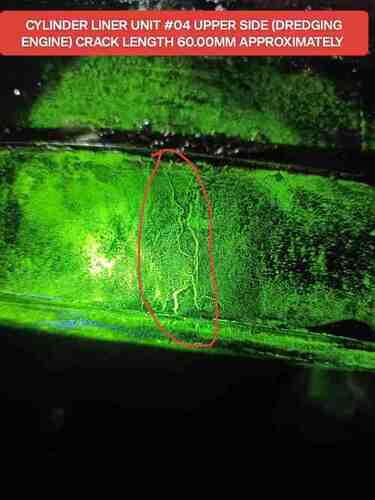

RA Power Solutions was approached by a company based in Dubai regarding a problem in the crankshaft of MAN 5L 16/24.

Action taken by RA Power Solutions for successful Repair

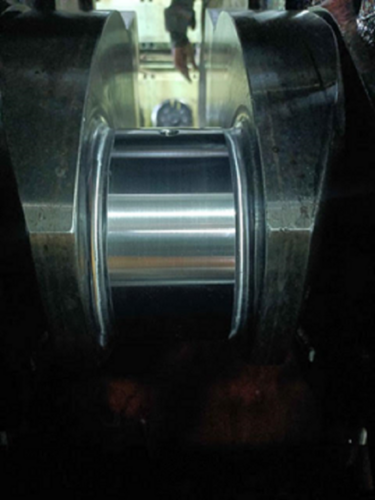

The grinding of crank pin no. 02 was started with a specially designed crankshaft grinding machine that can undertake grinding of crank pin of 130 mm diameter and can also sit on crankpin width of 56 mm only.

The grinding of crankpin no. 02 to the undersize of 1.5 mm was done. The crank pin diameter of crankpin no. 04 was also reduced by 1.0 mm.

The remaining crankpins were polished to remove the bearing line marks and improve the surface finish.

Superior Reconditioned Quality

Our MAN 5L 16/24 crankshaft repair engines are rehabilitated using stringent processes to achieve OEM standards. High-precision machining and polished surface treatments ensure the component delivers lasting performance for both marine and industrial applications. Comprehensive corrosion resistance safeguards operational longevity.

Tailored for Performance and Reliability

Every reconditioned crankshaft is crafted with high-grade alloy steel and undergoes a thorough forging technique. The result is an engine component that maintains structural integrity under heavy use, making it ideal for demanding marine or industrial engine environments.

FAQ's of Crankshaft Repair Engine MAN 5L 16/24:

Q: How is the MAN 5L 16/24 crankshaft repaired and reconditioned?

A: Our crankshafts are reconditioned through a precision machining process that involves high-tolerance grinding and careful inspection. Each unit is forged and polished to ensure a smooth finish, corrosion resistance, and compliance with original equipment manufacturer (OEM) specifications.Q: What makes this crankshaft suitable for marine and industrial engines?

A: This crankshaft is made from robust alloy steel and designed specifically for 5-cylinder inline diesel engines like the MAN 5L 16/24. Its high-strength forged construction and corrosion-resistant finish make it reliable for heavy-duty marine and industrial environments.Q: When should a crankshaft be considered for repair or replacement?

A: Crankshaft repair is recommended when there are signs of wear, cracks, scoring, or unbalanced operation. Prompt repair or replacement helps maintain engine efficiency and prevents costly breakdowns in marine and industrial uses.Q: Where is the reconditioned crankshaft manufactured and supplied from?

A: The reconditioned crankshaft is manufactured, reconditioned, and supplied from our facilities in India. We serve clients domestically and internationally as an exporter, manufacturer, and supplier.Q: What is the process for ordering a reconditioned MAN 5L 16/24 crankshaft?

A: To order, you can contact us directly with your engine specifications. Each crankshaft is carefully packed in a custom crate to ensure it arrives safely, and we offer worldwide shipping services.Q: How does the custom packaging benefit the crankshaft during transport?

A: Our custom crate packaging is designed to protect the crankshaft from damage, moisture, and corrosion during transit, ensuring it reaches the customer in optimal condition and ready for installation.Q: What are the key benefits of using a reconditioned crankshaft meeting OEM standards?

A: Using a reconditioned OEM-standard crankshaft ensures exceptional performance, reliability, and cost-effectiveness. It extends the service life of marine or industrial engines while maintaining factory-level specifications and quality.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Crankshaft Repair Category

Daihatsu 5DK-20 Engine Crankshaft Repair

Price 1500 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Onsite Crankshaft Grinding Machine

Price 300000 INR / Square Inch

Minimum Order Quantity : 1 , , Square Inch

Wartsila vasa 32LN Engine Crankpin Repair

Price 1600 USD ($) / Number

Minimum Order Quantity : 1 Square Inch

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free