In Place Machining of Damaged Intermediate Shaft Journal

MOQ : 1 Unit

In Place Machining of Damaged Intermediate Shaft Journal Specification

- Power Source

- Electric/hydraulic portable units

- Material Compatibility

- Carbon steel, alloy steel, stainless steel

- Tooling Type

- Specially designed portable cutting and grinding tools

- Inspection

- Post-machining dimensional and surface finish inspection provided

- Machining Tolerance

- Up to ±0.01 mm

- Surface Finish After Machining

- Up to 0.2 Ra

- Operation Environment

- Suitable for marine, power plants, industrial onsite locations

- Machining Technique

- Portable machining, in-place journal turning and grinding

- Safety Features

- Integrated safety interlocks, protective guards for onsite operation

- Service Availability

- 24/7 emergency response and planned maintenance contracts

- Application

- Onsite repair and restoration of worn or damaged intermediate shaft journals

- Journal Diameter Range

- Typically accommodates shaft journals from 100 mm to 1000 mm

- Setup Time

- Reduced downtime, average setup within 2-5 hours

- Product

- In Place Machining of Damaged Intermediate Shaft Journal

In Place Machining of Damaged Intermediate Shaft Journal Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 2-3 Days

About In Place Machining of Damaged Intermediate Shaft Journal

In place Machining of damaged intermediate shaft journal was executed successfully by RA Power Solutions at Kochi Port, India.

Details of Intermediate Shaft Repair

- Team of three technicians boarded the Vessel with the onsite grinding and polishing equipment.

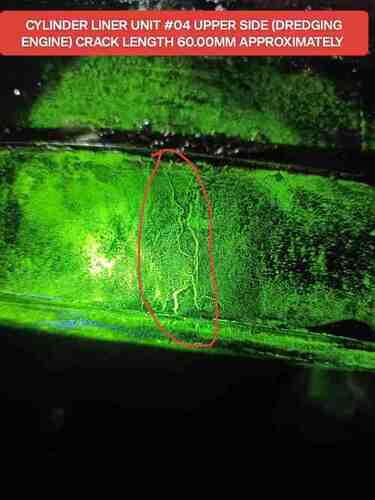

- On inspection the Intermediate Propeller Shaft bearing sitting diameter was found damaged with surface cracks, higher hardness, and ovality of 0.38MM.

- The bearing was found burnt and white metal removed, this bearing was immediately packed and sent to our factory for White Metal Rebabbitting to save the time.

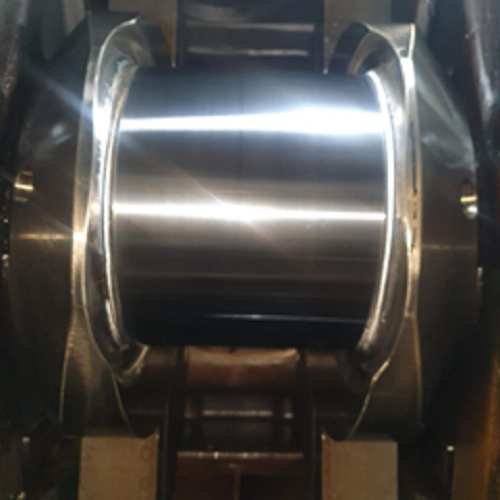

- Machining, Grinding and Polishing of Intermediate Shaft Journal was undertaken, and diameter was reduced by 1.00MM, the final diameter of Intermediate Shaft Journal was maintained as 504.00 MM with the tolerance of only 0.02 MM and surface finish of less than 15 Ra value.

- The bearing after rebabbitting was machined, in the RA Power Solutions factory maintaining the bore size of 504.50 MM, as per the manual.

- Bearing was assembled, Blue matching was done and after checking of Oil-gap and all other major parameters the trials were taken and performance was found satisfactory.

Efficient Onsite Restoration

Our in place machining service enables quick and precise restoration of damaged intermediate shaft journals directly at your location. The portable machining method eliminates the need for disassembly and transportation, significantly reducing repair times and associated costs.

Precision Engineering for All Environments

We support a wide variety of industries including marine, power plants, and industrial facilities. Our specialized tooling and robust power sources allow for accurate machining in challenging onsite environments, ensuring optimal shaft performance and equipment reliability.

Comprehensive Quality Assurance

Our in place machining includes stringent post-machining inspections to verify both dimensional accuracy and surface finish. Coupled with integrated safety systems and trained personnel, our service guarantees consistent quality and operational safety every time.

FAQ's of In Place Machining of Damaged Intermediate Shaft Journal:

Q: How is in place machining of a damaged intermediate shaft journal performed onsite?

A: In place machining is carried out using specially designed portable cutting and grinding tools, which are mounted directly onto the shaft at your facility. This process allows for turning and grinding of shaft journals without the need for removal, significantly shortening repair time and minimizing downtime.Q: What types of shaft journal materials can be machined with your onsite service?

A: Our portable machining service is compatible with carbon steel, alloy steel, and stainless steel shaft journals, ensuring versatility across various industrial applications.Q: When can I schedule onsite shaft journal machining, and is emergency service available?

A: We offer both 24/7 emergency response and planned maintenance contracts. You can schedule our onsite machining services any time, ensuring coverage for both urgent repairs and routine restoration needs.Q: Where is your in place machining service available?

A: Our onsite repair services are offered across India, catering to marine vessels, power plants, and industrial facilities in both urban and remote locations.Q: What is the typical machining tolerance and surface finish achieved after onsite repair?

A: Our process achieves a machining tolerance of up to 0.01 mm and delivers a surface finish as fine as 0.2 Ra, ensuring high quality and reliable shaft operation.Q: How long does it take to set up the in place machining equipment onsite?

A: Upon arrival, our team completes the machinery setup within 2 to 5 hours, enabling quick commencement of repairs and reducing overall equipment downtime.Q: What safety measures and post-machining inspections are included in your service?

A: Safety is prioritized with integrated safety interlocks, protective guards, and adherence to onsite protocols. Dimensional and surface finish inspections are conducted post-machining to verify compliance with specifications and ensure quality.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Crankshaft Repair Category

Onsite Crankshaft Grinding Machine

Price 300000 INR / Square Inch

Minimum Order Quantity : 1 , , Square Inch

Wartsila Crankshaft Repair and Crankshaft Grinding

Price 1500 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS