Peroni Pompe Crankshaft Repair

Price 1000.0 INR/ Number

Peroni Pompe Crankshaft Repair Specification

- Repair Location

- On-site or Workshop

- Technical Support

- Available

- Compatibility

- Suitable for Peroni Pompe Industrial Pumps

- Type

- Crankshaft Repair

- Quality Assurance

- ISO Certified Processes

- Service Provided

- Crankshaft Reconditioning & Repair

- Material Used

- High Grade Steel

- Surface Treatment

- Custom as required

- Maximum Shaft Length

- Up to 2000 mm

- Precision Machining

- Yes

- Application

- Industrial Pump Maintenance

Peroni Pompe Crankshaft Repair Trade Information

- Minimum Order Quantity

- 1 Square Inch

- Supply Ability

- 1 Square Inch Per Day

- Delivery Time

- 2-3 Days

About Peroni Pompe Crankshaft Repair

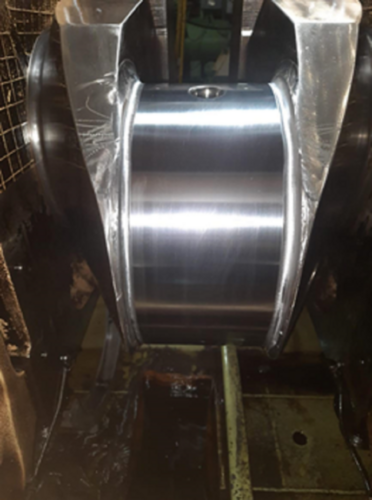

Undersize crankpin bearing for Peroni Pompe, Italy

After undersizing the crankpin to 1.5mm, the matching bearing was manufactured and supplied by RA Power Solutions. The Peroni Pompe, Italy, was assembled, and its performance has been observed to be satisfactory. For more information, please email us atrajshahani@rapowersolutions.com, orinfo@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.

We have been regularly providing our services in Italy, Canada, Australia, Bangladesh, Canada, Dubai, Greece, Haiti, Hong Kong, Indonesia, Kenya, Malaysia, Maldives, Kenya, Kuwait, Madagascar, Mexico, Nigeria, Oman, Philippines, Saint Lucia, Saudi Arabia, Singapore, Spain, Sint Maarten, Sri Lanka, Suriname, Thailand, Togo, United Kingdom, United States, Yemen, Zambia, etc.

Expert Crankshaft Reconditioning for Peroni Pompe Pumps

Our specialized service focuses on restoring crankshafts for Peroni Pompe industrial pumps using precision machining. Improvements in operational efficiency are achieved through expert techniques and ISO-certified quality protocols. Clients can select between on-site or workshop repair depending on convenience and project requirements.

Tailored Solutions for Diverse Industrial Needs

Whether dealing with emergency breakdowns or scheduled maintenances, we provide crankshaft repairs and reconditioning for shafts up to 2000 mm using high-grade steel. Our surface treatments are fully customizable, ensuring compatibility with various industrial operating conditions and extending pump service life.

FAQ's of Peroni Pompe Crankshaft Repair:

Q: How is the crankshaft repair process carried out for Peroni Pompe pumps?

A: The repair process begins with a detailed assessment of the crankshaft, followed by precision machining and reconditioning using high-grade steel. Surface treatment is customized as required, ensuring compliance with ISO-certified standards for reliability and longevity.Q: What types of Peroni Pompe pumps are compatible with this crankshaft repair service?

A: This service is specifically tailored for Peroni Pompe industrial pumps. The repaired crankshaft can be used in any compatible pump within the specified shaft length limit of 2000 mm.Q: When should I consider crankshaft repair or reconditioning for industrial pumps?

A: Repair is advisable when there are signs of wear, cracks, imbalance, or performance drop. Early intervention prevents major breakdowns and extends pump lifespan, minimizing costly downtime.Q: Where can the crankshaft repair be performed?

A: Repairs can be conducted either on-site at your facility for quicker turnaround or at our specialized workshops, depending on the size and logistical needs of the project.Q: What surface treatments are available for the repaired crankshaft?

A: Surface treatments are customized based on your operational requirements. Options include enhanced corrosion resistance, hardening, and precision finishing to improve durability under various industrial conditions.Q: What is the main benefit of choosing your ISO-certified crankshaft repair service?

A: The primary advantage is assured quality and reliability due to strict adherence to ISO-certified processes, coupled with high-grade materials and technical support for optimal pump performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Crankshaft Repair Category

Wartsila Engine Model no. 6R32, 4R32, 8R32, 9R32, 12V32LN, 16V32D, 16V32LN, W16V32, W18V32 Crankpin Repair | Crankshaft Grinding Onsite

Price 5000 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Crankshaft Repair of MAN B&W 6L 16/24

Price 1000.0 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Repair of Sulzer Engine 6ZAL 40S Crankshaft

Price 1600 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS