Rebabbitting of White Metal Bearings Manufacturer For 43 Years

Price 16000 USD ($)/ Number

Rebabbitting of White Metal Bearings Manufacturer For 43 Years Specification

- Inside Diameter

- Customized to requirement

- Precision Rating

- Up to ISO or DIN Standard

- Retainer

- Fitted/As required

- Thickness

- Adjustable, typically from 3 mm up

- Cage Material

- As per Customer Specification

- Lubrication Type

- Oil or Grease

- Bearing Type

- White Metal / Babbitt Journal Bearing

- Material

- High-Grade White Metal (Babbitt) Alloy

- Structure

- White Metal Bearing

- Seals Type

- Standard/Custom (as required)

- Number Of Rows

- Single and Double Row (as per requirement)

- Bore Size

- Custom as per OEM/Client Specs

- Outside Diameter

- Upto 1500 mm or as specified

- Limiting Speed

- As per OEM specification

- Load Capacity

- Designed as per application

- Service Offered

- Rebabbitting (Re-metalling) of old/used bearings

- Application

- Used in Turbines, Generators, Pumps, Motors, Marine Engines, Compressors

- Testing

- Ultrasonic Crack Detection, Metallurgical Test, Dynamic Balancing

- Size Range

- Small to Large Bearings

- OEM Capability

- Yes (Reverse Engineering Possible)

- Base Bonding

- Guaranteed Bond Strength via Centrifugal/Static Casting

- Customization

- Available as per Drawing/Sample

- Finish

- Precision Machined & Inspected

- Repair & Inspection

- Comprehensive Inspection & Defect Analysis

- Manufacturing Experience

- 43 Years in Babbitt Bearings

Rebabbitting of White Metal Bearings Manufacturer For 43 Years Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 1 Number Per Day

- Delivery Time

- 2-3 Days

About Rebabbitting of White Metal Bearings Manufacturer For 43 Years

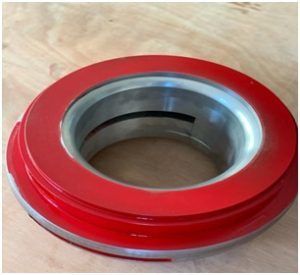

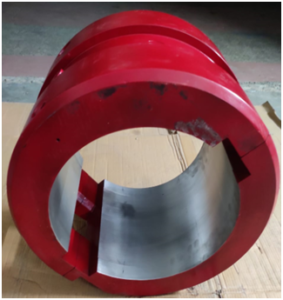

RA Power Solutions undertakes rebabbitting ofold, worn out and damagedbearings up to 1500mm diameter for large industrial and marine companies. The rebabbitting is undertaken using the different grades of Babbitt white metal as per international standards. All the bearings rebabbitting is undertaken by a centrifugal process which resultstothe perfect bonding with the steel casing of the bearings.

We manufacture Babbitt bearings as per the drawing and requirement of the client.We have in-house facilities to manufacture white metal engine bearings, white metal pump shaft bearings, white metal turbine bearings, white metal alternator bearings, white metal rotor shaft bearings, white metal crankshaft bearings, and white metal bearings for all sizes of shafts ranging from 60mm to 1500mm.

With a focus on customer satisfaction, RA Power Solutions caters to a diverse range of industries, including power generation, marine, and heavy engineering. Their white metal bearings are designed to withstand extreme conditions, providing long-lasting solutions that contribute to the efficiency and longevity of machinery.

We are dedicated to providing comprehensive solutions, including installation and maintenance services, ensuring that our clients experience seamless operations and minimal downtime

We are conveniently situated near New Delhi, India (International Airport) and can facilitate the necessary arrangements for import and re-export after repairs promptly and cost-effectively. This is the primary reason we serve more than 36 countries, meeting their critical needs for new white metal Babbitt bearings and providing rebabbitting services for damaged bearings.

Comprehensive Rebabbitting and Manufacturing Services

We offer specialized rebabbitting (re-metalling) services for old or worn white metal bearings, restoring them to optimal working condition. Our manufacturing capabilities extend to new bearings, supporting diverse industrial needs with options for both single and double row configurations, customized dimensions, and precise finishes as per ISO or DIN standards.

Advanced Inspection and Testing Assured

Every bearing undergoes comprehensive inspection and defect analysis, including ultrasonic crack detection, metallurgical testing, and dynamic balancing. These procedures ensure the longevity, performance, and safety of your equipment, providing you confidence in the reliability of our products.

Custom Solutions for Varied Applications

Whether you require bearings for turbines, marine engines, pumps, or compressors, our experience allows us to deliver tailored solutions. Reverse engineering from OEM specs, samples, or drawings, and flexible options for seals, cage material, and lubrication types ensure that each bearing perfectly suits your operational needs.

FAQ's of Rebabbitting of White Metal Bearings Manufacturer For 43 Years:

Q: How does the rebabbitting process work for used white metal bearings?

A: Rebabbitting involves removing the old or worn layer of Babbitt alloy from the bearing shell and applying a new layer using centrifugal or static casting methods. After re-metalling, the bearing undergoes precision machining and thorough inspection to restore its original performance and ensure bond strength.Q: What are the key benefits of choosing your rebabbitting services?

A: Our rebabbitting service extends the operational life of bearings, offers cost savings compared to new replacements, and maintains high performance through state-of-the-art testing, including ultrasonic crack detection and metallurgical analysis. We also ensure guaranteed bond strength and custom finishes tailored to your requirements.Q: When should I consider rebabbitting my bearings instead of replacing them?

A: Rebabbitting is recommended when the bearing's white metal surface shows signs of wear, scoring, or cracking. If the base structure is still sound, rebabbitting offers a cost-effective alternative to complete replacement, restoring the bearing to as-new performance.Q: Where can your bearings be used, and do you accommodate custom applications?

A: Our bearings are used across turbines, generators, marine engines, pumps, compressors, and motors. We offer customization in size, bore, outside diameter, sealing, and materials, supported by our expertise in reverse engineering from OEM drawings or samples.Q: What testing and inspection procedures do you follow for bearings?

A: Each bearing undergoes ultrasonic crack detection, metallurgical testing, dynamic balancing, and comprehensive defect analysis. These rigorous processes ensure durability, reliability, and adherence to ISO and DIN quality standards.Q: How is the load capacity and speed rating determined for custom bearings?

A: Load capacity and limiting speed are calculated based on the application's operational requirements and OEM specifications. Our experienced engineers ensure each bearing is designed for optimal performance within its intended machinery.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in White Metal Bearing Category

White Metal Engine bearing

Price 3200 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Inside Diameter : 50 mm

Bore Size : 50 mm

Precision Rating : ISO Grade 7

Load Capacity : High

Babbitt White Metal Mearing Repair

Price 3400 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Inside Diameter : Custom

Bore Size : Custom

Precision Rating : ISO 9001:2015

Load Capacity : High

Rebabbitting Of Old Bearing

Price 3200 USD ($) / Piece

Minimum Order Quantity : 1 , , Piece

Inside Diameter : Custom as per requirement

Bore Size : Custom as per old bearing

Precision Rating : ISO Standard

Load Capacity : Heavy Duty

Babbitt White Metal Ingots

Price 3300-70000 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Inside Diameter : Customizable

Bore Size : Customizable

Precision Rating : Industrial Grade

Load Capacity : High

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS