Repair of Wartsila 4L20 Crankshaft

Price 16000 INR/ Square Inch

Repair of Wartsila 4L20 Crankshaft Specification

- Warranty on Repair

- 6-12 months

- Repair Service Type

- Reconditioning, Grinding, Polishing, Straightening

- Surface Finish After Grinding

- Ra 0.2 0.4 m

- Certification Provided

- Repair Process Certificate

- Typical Applications

- Marine engines, Power plants

- Crankshaft Material

- Forged Steel

- Service Location

- On-site/Workshop

- OEM Reference Standard

- Wartsila Specifications

- Emergency Repair Availability

- Yes

- Engine Model Supported

- Wartsila 4L20

- Hardness After Repair

- 240-260 HB

- Minimum Diameter Tolerance

- as per OEM Standard

- Inspection Methods Used

- Magnetic Particle Inspection, Ultrasonic Testing

- Component

- Crankshaft

Repair of Wartsila 4L20 Crankshaft Trade Information

- Minimum Order Quantity

- 1 Square Inch

- Supply Ability

- 1 Square Inch Per Day

- Delivery Time

- 2-3 Days

About Repair of Wartsila 4L20 Crankshaft

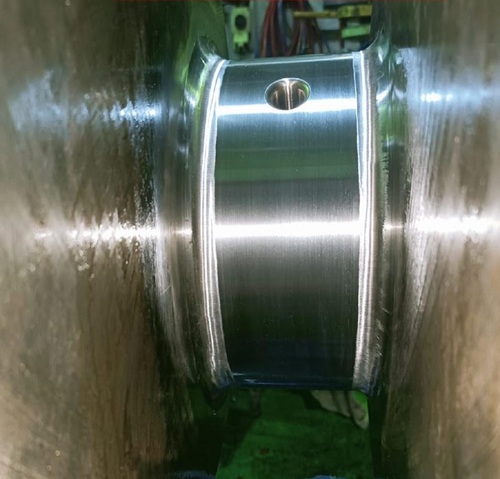

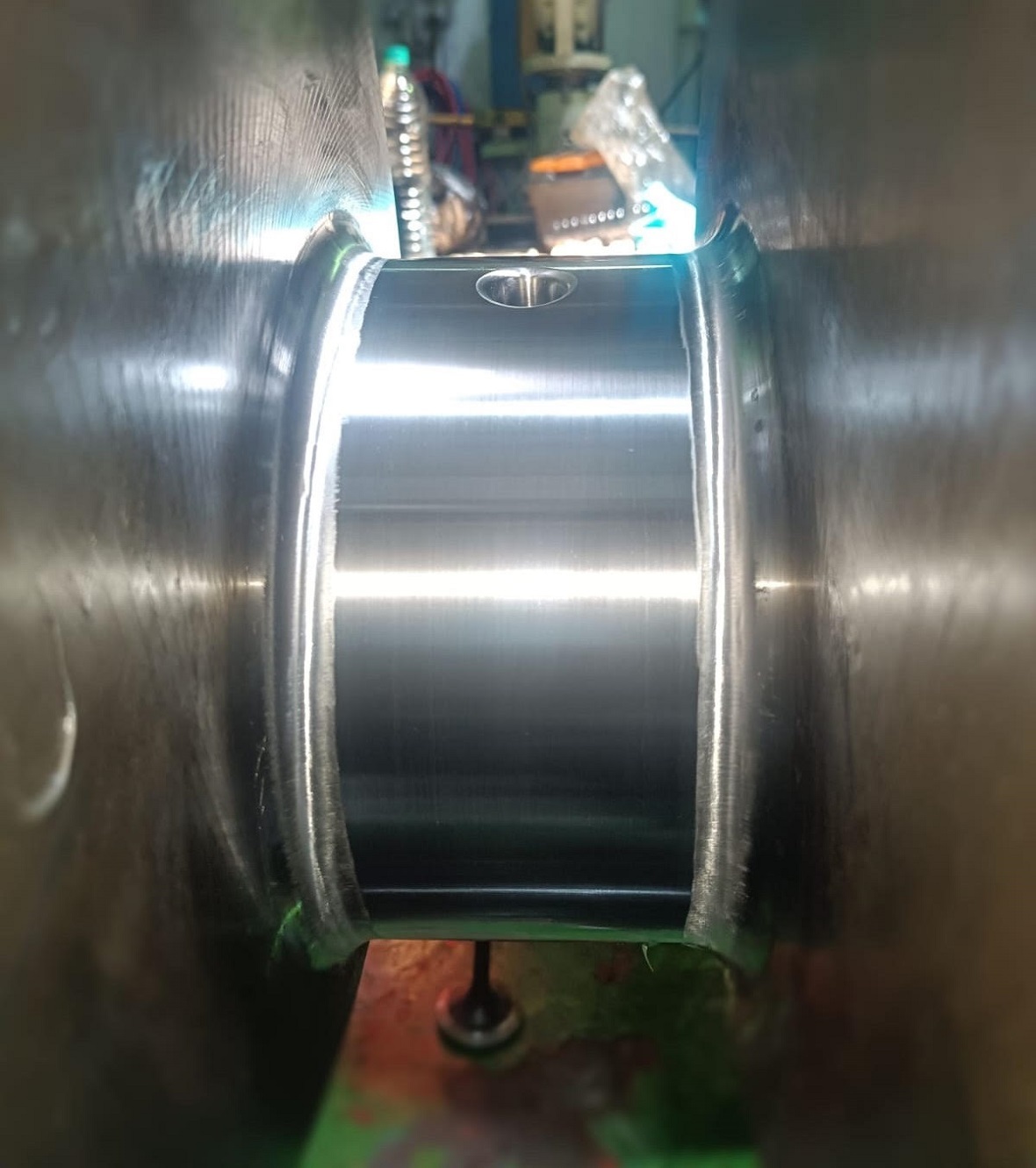

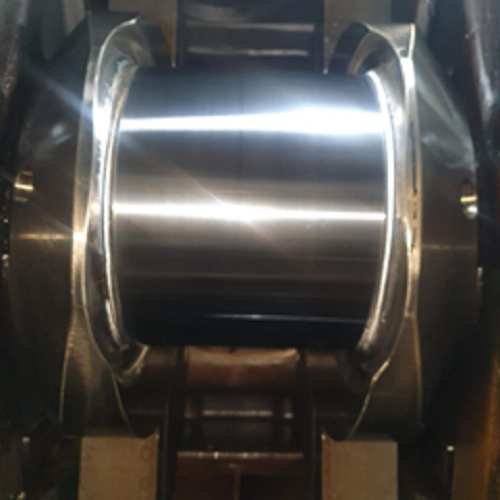

RA Power Solutions successfully repaired a Wartsila 4L20 crankshaft on board a vessel while sailing. The vessel was owned by a reputed shipping company based in Kuwait. The crankshaft was removed from the engine block due to a serious accident that damaged the crankcase beyond repair.

The repair of the Wartsila 4L20 crankshaft was a complex and challenging task. However, the RA Power Solutions technicians were able to successfully complete the repair and the vessel was able to continue sailing without any problems

Reliable Crankshaft Reconditioning

Specializing in servicing Wartsila 4L20 crankshafts, our repair solutions restore OEM-standard dimensions, hardness, and surface integrity. Each crankshaft undergoes rigorous straightening, grinding, and polishing by skilled technicians, making it suitable for critical marine and power plant applications. Our strict adherence to Wartsila specifications ensures optimal performance and reliability after repair.

Advanced Inspection & Quality Assurance

Qualified engineers utilize both Magnetic Particle Inspection and Ultrasonic Testing at every repair stage. These non-destructive tests ensure the repaired crankshaft is free from surface and internal defects and maintains the specified hardness and finish. Every job comes with a repair process certificate, guaranteeing our commitment to stringent quality standards and customer satisfaction.

Flexible, Certified Service Across India

Our repair operations are available both onsite and in our fully equipped workshop, reducing downtime and logistics challenges for marine, power generation, and industrial operators. Fast emergency repairs, warranty coverage, and certification provide confidence and convenience for exporters, manufacturers, and service providers nationwide.

FAQ's of Repair of Wartsila 4L20 Crankshaft:

Q: How is the Wartsila 4L20 crankshaft repaired and what repair processes are applied?

A: The Wartsila 4L20 crankshaft undergoes a comprehensive reconditioning process which includes straightening, precision grinding, and polishing to OEM standards. This process restores the correct hardness (240-260 HB) and achieves a surface finish between Ra 0.2-0.4 m, ensuring long-term engine performance.Q: What inspection methods ensure the quality of the crankshaft repair?

A: Each repaired crankshaft is inspected using Magnetic Particle Inspection to reveal surface cracks and Ultrasonic Testing for detecting internal flaws. This dual approach guarantees the crankshaft meets both OEM standards and safety regulations.Q: When and where can emergency repair services be provided?

A: Emergency repair services are available 24/7 at both client sites and our dedicated workshop across India. This rapid response minimizes downtime, especially for critical marine and power plant operations.Q: Where is the service available and which engine models are supported?

A: Our crankshaft repair services are available throughout India, supporting Wartsila 4L20 engine models used in marine vessels and power plants, catering to exporters, manufacturers, suppliers, and traders.Q: What certifications and warranties are provided with the repair?

A: Every completed repair comes with a Repair Process Certificate verifying adherence to Wartsila specifications. We also offer a warranty of 6-12 months, ensuring customer confidence in the durability and quality of our work.Q: How does this repair service benefit marine and power plant operators?

A: Reconditioning Wartsila 4L20 crankshafts reduces costly replacements, extends engine life, and ensures continued operational efficiency. With optimized hardness, precise finishing, and quick turnaround times, operators can rely on safer, uninterrupted performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Crankshaft Repair Category

Crankshaft Repair/ Crankshaft Machining Services in Ecuador

Price 1500 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Crankshaft Repair of MAN B&W 6L 16/24

Price 1000.0 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Wartsila Crankshaft Repair and Crankshaft Grinding

Price 1500 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

MAN 9 ASL 25/30 Crankshaft Repair/in situ Crankshaft Grinding RA Power Solutions

Price 1500 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free