Wartsila Bearing Rebabbitting

Price 10000 INR/ Number

Wartsila Bearing Rebabbitting Specification

- Inside Diameter

- Customized

- Lubrication Type

- Oil Lubrication

- Precision Rating

- ISO

- Thickness

- Custom as per requirement

- Bearing Type

- Journal / Main Engine Bearing

- Material

- Steel Backed With White Metal (Babbitt)

- Structure

- Cylindrical

- Seals Type

- Open

- Number Of Rows

- Single

- Bore Size

- Customized

- Outside Diameter

- Customized

- Limiting Speed

- As per Wartsila specifications

- Load Capacity

- High Performance

- OEM Compatibility

- Yes, for Wartsila models

- Manufacturing Process

- Centrifugal/Static Casting

- Standard

- Conforms to OEM Specifications

- Coating

- White Metal (Babbitt Metal)

- Condition

- Rebabbitted (Refurbished as per OEM standard)

- Application

- Marine Engine, Auxiliary Engine, Main Engine Bearings

- Customization

- Available as per drawing/sample

- Temperature Resistance

- Up to 120°C operating temperature

- Surface Finish

- Ground & Polished

- Corrosion Resistance

- High due to Babbitt layer

- Hardness

- Typically 22-30 HRC

- Service Life

- Extended with proper maintenance

- Repair Service

- On-site Rebabbitting Available

Wartsila Bearing Rebabbitting Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 1 Number Per Day

- Delivery Time

- 2-3 Days

About Wartsila Bearing Rebabbitting

RA Power Solutions was approached by a Russian Company based in Yekaterinburg, Russia regarding their urgent requirement of repair of Generator Bearing of Wartsila.

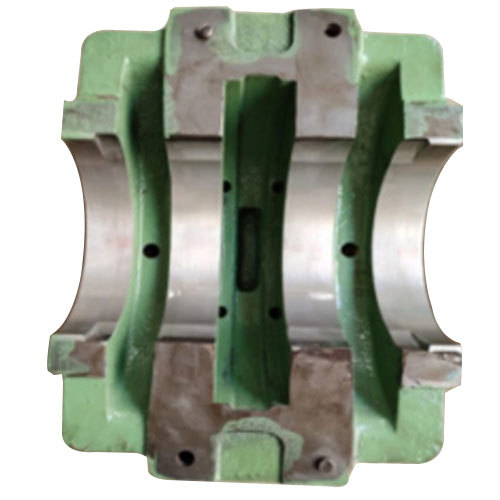

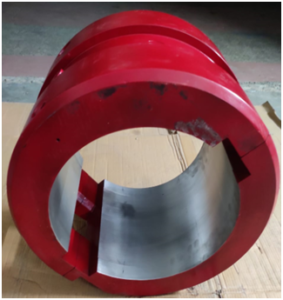

| Damage Wartsila Generator Bearing | Wartsila Generator Bearing Babbitt White Metal Damaged |

The Generator Bearing was air freighted to us for repair, following are the main dimensions of the Generator Bearing:

| S.NO | Description | Standard Dimensions with Tolerance as Per Drawing |

| 1. | Bearing Inner Dia (Bore) | 250.00 (0.03) |

| 2. | Bearing 2nd Inner Dia | 266.00MM |

| 3. | Bearing Outer Diameter | 507.00MM |

| 4. | Bearing White Metal Width | 250.00MM |

| 5. | Bearing Total Width | 263.00MM |

| 6. | Client | Based in Yekaterinburg, Russia |

| Rough Drawing of Wartsila Generator Bearing | Shaft Diameter on Which Bearing is Assembled |

| Photo Showing Wartsila Made Generator Bearing |

|

|

Pre-Inspection of Generator Bearing of Wartsila :

| Wartsila Generator Bearing Inspection under Process | Wartsila Generator Bearing After Rebabbitting |

|

|

|

RA Power solutionshaving 44 Years of experience undertakes rebabbitting of large bearings up to 1500 MM diameter, New bearings are also manufactured, as per the drawing or a sample.

| Wartsila Generator Bearing After Repair | Wartsila Generator Bearing Ready for Dispatch |

Developing and manufacturing bearings as large as 1500 mm in diameter is no small feat. It speaks volumes about RA Power Solutions' expertise in metallurgy, precision engineering, and quality control. These bearings are crucial for ensuring smooth operation and longevity in industrial machinery, where performance and reliability are paramount.

For more information regardingrepair of Generator Bearing of Wartsila, please contact us at rajshahani@rapowersolutions.com or info@rapowersolutions.com or call us at +91 9582647131 or +91 9810012383.

Expert Rebabbitting for Marine Engine Bearings

Our rebabbitting service offers a reliable solution for extending the life of marine auxiliary and main engine bearings. The process involves refurbishing bearings to OEM standards using white metal coatings for optimal wear, resistance, and durability. With in-house precision machining and on-site options, clients benefit from reduced downtime and tailored solutions for Wartsila applications.

Enhanced Performance and Protection

By utilizing high-quality Babbitt metal and advanced casting techniques, we ensure your cylindrical, steel-backed bearings offer superior corrosion protection and oil lubrication. The result is extended bearing service life, high load capacity, and performance that meets or exceeds original manufacturer requirements, even under demanding marine conditions.

FAQ's of Wartsila Bearing Rebabbitting:

Q: How does the Wartsila Bearing Rebabbitting process work?

A: The process involves removing old or worn white metal layers, cleaning and preparing the steel backing, and then applying a new Babbitt metal layer through centrifugal or static casting. After casting, the bearing is precision-machined, ground, and polished to OEM specifications.Q: What types of engines can use rebabbitted Wartsila bearings?

A: Rebabbitted bearings are suitable for a wide range of marine engines, including main and auxiliary engines, as well as journal and main engine bearing applications in Wartsila models.Q: When is it recommended to choose bearing rebabbitting over replacement?

A: Rebabbitting is ideal when the bearing structure is still intact but the Babbitt layer shows signs of wear or scoring. This option is cost-effective and extends bearing life while maintaining performance to original standards.Q: Where can rebabbitting services be carried out?

A: We provide on-site rebabbitting services as well as in-house refurbishment at our facility, depending on client requirements and the nature of the repair needed.Q: What benefits does rebabbitting offer compared to new bearing replacement?

A: Rebabbitting restores bearings to OEM standard, is more economical than complete replacement, and offers quick turnaround, especially with on-site service. It extends service life and maintains engine reliability with proper maintenance.Q: Can bearings be customized during the rebabbitting process?

A: Yes, we can customize bore size, outside diameter, thickness, and more as per your supplied drawing or sample, ensuring perfect compatibility and performance for your specific application.Q: What is the typical service life and operating temperature for rebabbitted bearings?

A: With proper maintenance, rebabbitted bearings maintain extended service life and operate efficiently at temperatures up to 120C, providing long-lasting performance in marine environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in White Metal Bearing Category

Babbitt Bearing

Price 3500 USD ($) / Piece

Minimum Order Quantity : 1 , , Piece

Inside Diameter : Customizable as per requirement

Material : Other, Babbitt Metal (Lead or Tin Based Alloy)

Number Of Rows : Single Row

Thickness : Varies as per dimension

Babbitt White Metal Mearing Repair

Price 3400 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Inside Diameter : Custom

Material : Other, White Metal/Babbitt Alloy

Number Of Rows : Other, Single

Thickness : As per Specification

Trimetal Bearing

Price 3100 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Inside Diameter : 35 mm

Material : Other, Steel/Copper/Lead Bronze

Number Of Rows : Single Row

Thickness : 6 mm

Rebabbitting Of Old Bearing

Price 3200 USD ($) / Piece

Minimum Order Quantity : 1 , , Piece

Inside Diameter : Custom as per requirement

Material : Other, HighQuality White Metal (Babbitt alloy)

Number Of Rows : Other, Single

Thickness : As per standard or old bearing

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS