Crack Repair of Cylinder Liners

Price 1500 INR/ Square Inch

Crack Repair of Cylinder Liners Trade Information

- Minimum Order Quantity

- 1 Square Inch

- Supply Ability

- 1 Square Inch Per Day

- Delivery Time

- 2-3 Days

About Crack Repair of Cylinder Liners

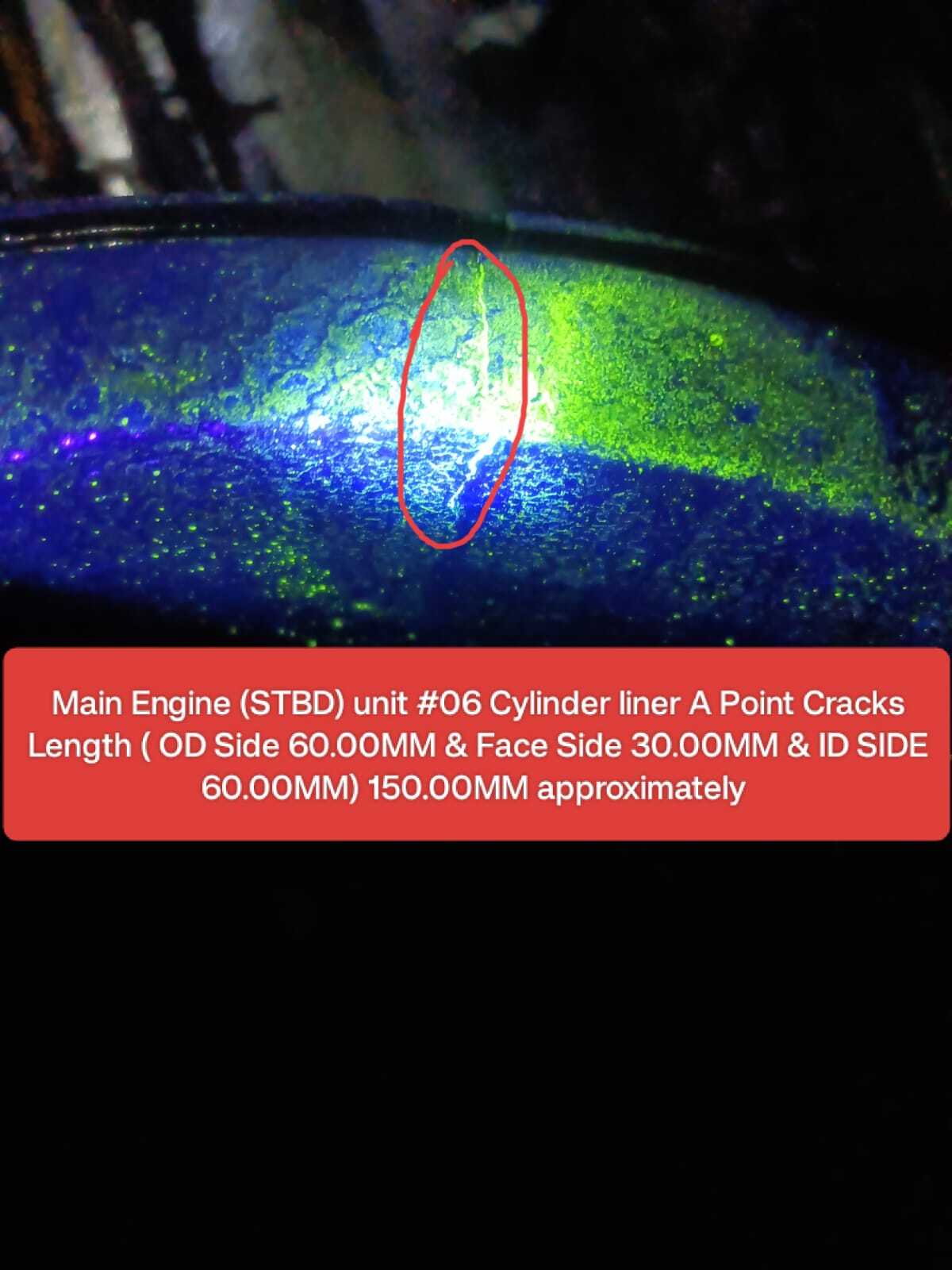

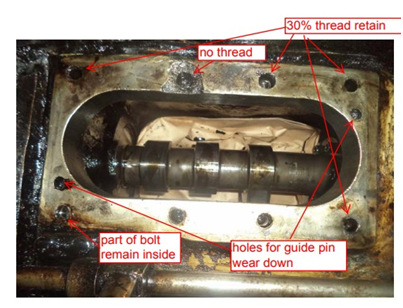

RA Power Solutions has saved a number of engines by undertaking the repair of damaged, cracked cylinder liners using the metal locking and metal stitching process. Below, we provide a photograph ofMAN engine cylinder linersthat have been repaired by us.

We regularly undertake the repair of engine blocks, compressors, and all cast iron, bronze, and aluminum components for the following engine makes:

- Akasaka

- Mitsubishi

- Daihatsu

- Yanmar

- Hanshin

- Kobe Mitsubishi

- Caterpillar

- Wartsila

- Deutz-KHD

- Volvo Penta SKL

- MAK

- Sulzer

- MAN B&W

- SKL

- MTU MAK

- Pielstick

We have been regularly providing metal stitching,metal locking, metal surgery, and repair services in Iraq, Iran, Dubai, Oman, Saudi Arabia, Singapore, Russia, Qatar, Abu Dhabi, Sharjah, Ajman, Umm Al-Quwain, Fujairah, Bahrain, Gambia, Kuwait, Antigua and Barbuda, Belize, Dominica, Dominican Republic, Malaysia, Indonesia, Madagascar, Vietnam, Grenada, Guyana, Haiti, Jamaica, Saint Kitts and Nevis, Saint Lucia, South Korea, Saint Vincent and the Grenadines, Trinidad, and Tobago, etc.

For more details onrepair of engine blocks, metal surgery, and MAN engine cylinder liners please email us at rajshahani@rapowersolutions.com, orinfo@rapowersolutions.com, or call us at +91 9582647131 or+91 9810012383.

Advanced Metal Stitching Solutions

Our repair process employs time-tested metal stitching and locking methods, which effectively restore structural integrity without the need for heat. The result is a robust, long-lasting solution suitable for heavy-duty cylinder liners in diverse industries.

Comprehensive Testing and Warranty

Each repair undergoes hydrostatic and non-destructive testing (NDT) to verify durability and leak resistance. For peace of mind, all serviced liners are covered by a one-year warranty against leakage, assuring utmost reliability.

On-Site & Workshop Flexibility

We provide both on-site repairs and workshop-based solutions, accommodating urgent needs and minimizing machinery downtime. Our mobile teams and well-equipped facilities in India ensure convenience and rapid service, wherever required.

FAQ's of Crack Repair of Cylinder Liners:

Q: How is the crack repair process carried out on cylinder liners?

A: The repair involves cleaning the affected area, carefully removing the crack, and employing metal stitching or metal locking. This technique mechanically joins the crack before a final machining ensures a smooth surface finish. Rigorous testing follows to verify the repair.Q: What maximum crack length and minimum liner thickness do you repair?

A: We repair cracks up to approximately 1.5 meters in length and can handle cylinder liners with a minimum wall thickness of 10 mm, accommodating a wide range of sizes and engine types.Q: Where can your crack repair services be availed?

A: Our services are available both on-site at client facilities and at our dedicated workshop, allowing flexibility based on your operational requirements and urgency.Q: What types of testing are performed after the repair?

A: After completion, each cylinder liner undergoes hydrostatic testing and non-destructive testing (NDT) to ensure there are no leaks or structural weaknesses remaining.Q: When does the repair warranty apply, and what does it cover?

A: A one-year warranty against leakage covers every repair, starting from the service date. This guarantees the reliability and quality of our workmanship during the specified period.Q: Is the repair service customizable for different engine types or liner sizes?

A: Yes, our crack repair solutions are tailored according to the liner size, crack category, and specific requirements of marine, industrial, and diesel engine applications.Q: What are the key benefits of choosing metal stitching for liner crack repair?

A: Metal stitching provides a non-invasive, heat-free, and durable repair method that maintains liner integrity with minimal downtime. The process results in a smooth machined finish and is suitable for both minor and extensive cracks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Metal Stitching Category

Metal Stitching Of Crack Casting

Price 1500 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Metal Stitching

Price Range 190000.00 - 3500000.00 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Cylinder Liner/ Engine Block/ Crack Repair of MAN Main Engine/ Metal Lock and Metal Stitching

Price 122018 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Cast Iron Crack Repair

Price Range 160000.00 - 900000.00 INR / Square Inch

Minimum Order Quantity : 1 , , Square Inch

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS