Crack Repair of Engine Block

Price 1600.0 INR/ Square Inch

Crack Repair of Engine Block Specification

- Professional Service

- Recommended for best results

- Usage/Application

- Repair of cracks and damages in engine blocks

- Post-repair Testing

- Pressure and integrity testing conducted

- Strength

- High mechanical strength post-repair

- Temperature Resistance

- Up to 250°C

- Corrosion Resistance

- Enhanced with specialized materials

- Repair Process

- Cold Welding / Metal Stitching / Epoxy Application

- Preparation Requirement

- Surface cleaning required before repair

- Environmental Impact

- Low, repair does not require complete block replacement

- Pressure Resistance

- Handles high internal engine pressures

- Repair Time

- Typically 2-8 hours depending on crack size

- Product Name

- Crack Repair of Engine Block

- Type

- Welding and Metal Stitching

- Durability

- Long-lasting and heat resistant

- Material Compatibility

- Cast Iron, Aluminum, Steel Engine Blocks

- Surface Finish

- Smooth finish post repair

- Suitable For

- Automobiles, Generators, Industrial Engines

- Appearance Post Repair

- Minimal visual evidence of previous damage

- Service Location

- Workshop / On-site

Crack Repair of Engine Block Trade Information

- Minimum Order Quantity

- 1 Square Inch

- Supply Ability

- 1 Square Inch Per Day

- Delivery Time

- 2-3 Days

- Main Domestic Market

- All India

About Crack Repair of Engine Block

Crack repair of heavy components is undertaken onsite by RA Power Solutions having more than 44 Years of experience. The heavy cast components, which get seriously damaged into multiple pieces, are repaired by preparing a new piece of Casting and Metal locking/Metal Stitching process. The repair of seriously damaged cast components and crack is executed with guarantee.

We Undertake Crack Repair of Following Components and Equipment

- Components Manufactured out of Cast Iron, Cast Steel, etc.

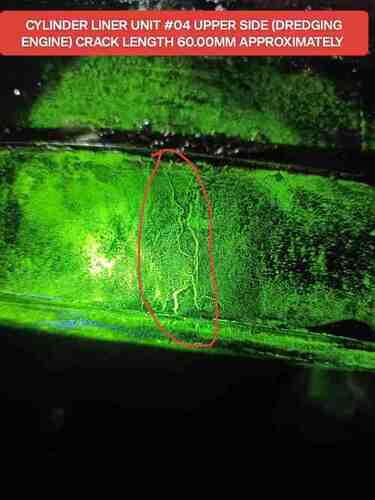

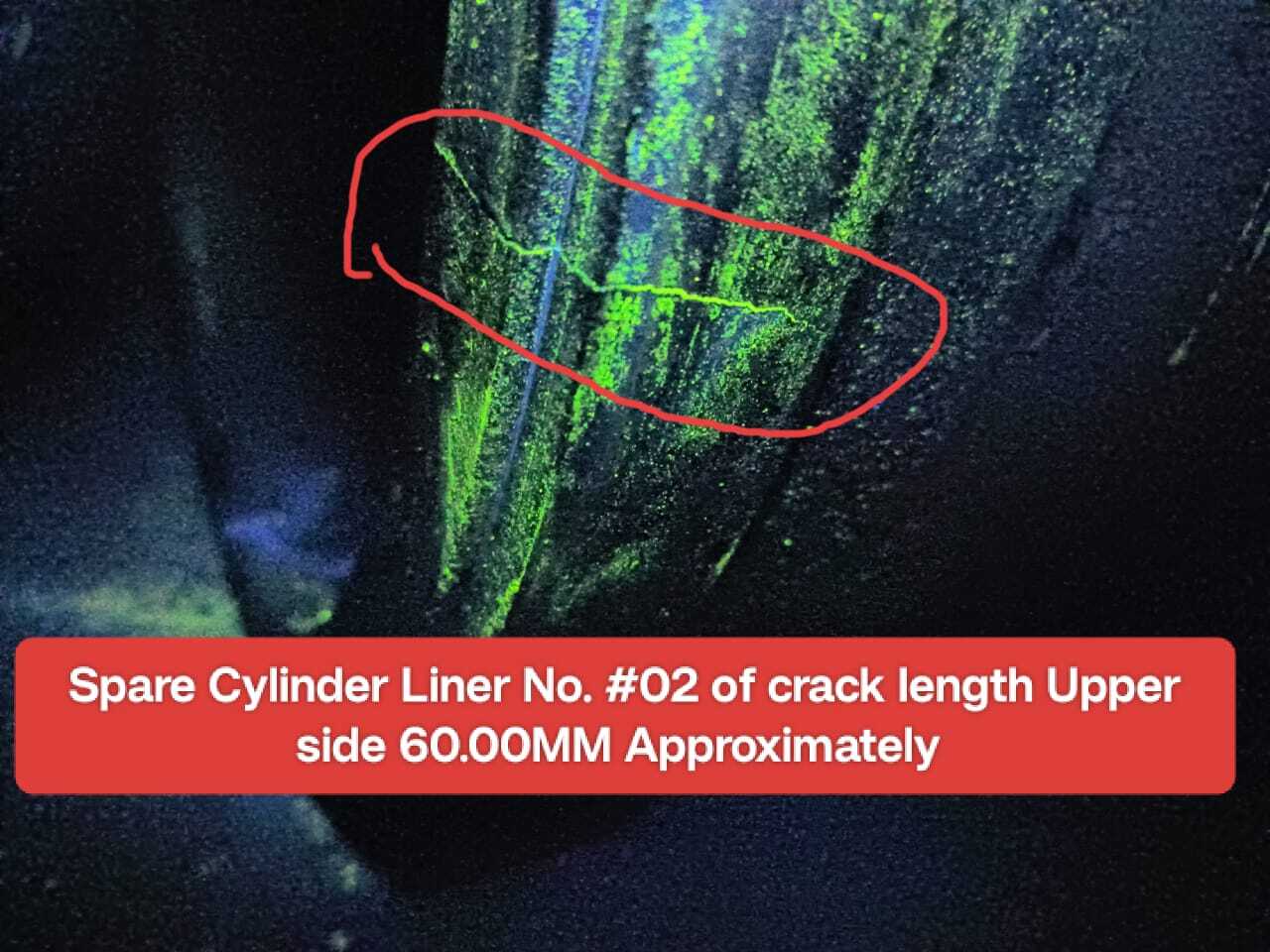

- Cylinder Liners, Cylinder Blocks, and Components Having Higher Hardness.

- Piston Manufactured Out of Aluminium

- Bronze Components

RA Power Solutions regularly undertakes repair of main engine components, which develop multiple cracks at different locations and length.

For more information on metal stitching repair of engine block crack and Crack in Cylinder Liner please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.

Comprehensive Engine Block Restoration

Our engine block crack repair service offers robust restoration for damaged blocks in automobiles, generators, and industrial engines. The repair methods-cold welding, metal stitching, and epoxy techniques-are selected based on material compatibility for cast iron, steel, or aluminum blocks. The process yields high mechanical strength and heat resistance, ensuring engine reliability and longevity with minimal post-repair evidence.

Efficient and Environmentally Conscious Repairs

This service eliminates the need for complete block replacement, reducing environmental impact and saving costs. With repair times typically ranging from 2 to 8 hours depending on crack size, clients benefit from efficient turnaround and durable results under high-pressure and high-temperature engine conditions. Specialized materials also enhance corrosion resistance, promoting long-term engine performance.

FAQ's of Crack Repair of Engine Block:

Q: How is the crack repair process for engine blocks performed?

A: Crack repair involves cleaning the affected surface thoroughly, then using suitable methods like cold welding, metal stitching, or epoxy application. The chosen technique depends on the block material, ensuring optimal mechanical strength and integrity after repair.Q: What types of engine blocks are compatible with this repair service?

A: This service is suitable for cast iron, aluminum, and steel engine blocks found in automobiles, generators, and industrial engines. Material-specific techniques are employed to maintain durability and performance.Q: When is crack repair recommended for an engine block?

A: Crack repair is advised when visual or pressure-related symptoms indicate damage but the block is structurally viable. Early intervention prevents further complications and can be completed within 2 to 8 hours, depending on crack severity.Q: Where can engine block crack repair be carried out?

A: Repairs can be conducted at professional workshops or, for some cases, on-site at the client's location. Expert technicians are equipped to deliver high-precision results in either setting.Q: What preparation is required before starting crack repair on an engine block?

A: It is essential that the engine block surface is thoroughly cleaned to ensure the repair materials bond effectively. This step contributes significantly to the long-term endurance of the repair.Q: What are the benefits of choosing crack repair over block replacement?

A: This approach is cost-effective and environmentally friendly, as it preserves the original block and avoids the material waste associated with full replacement. Post-repair, the block is tested for integrity and pressure, and exhibits enhanced corrosion resistance with a smooth finish.Q: Is professional service necessary for engine block crack repair?

A: Professional service is highly recommended to ensure the correct technique is applied and that thorough pressure and integrity testing is conducted after repair. This optimizes the block's structural and operational reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Crankshaft Repair Category

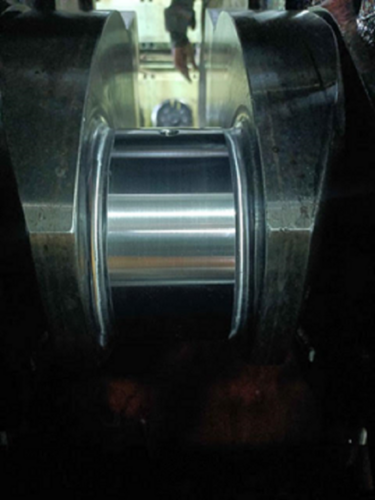

Insitu And Onsite Crankshaft Journal Repair/ Crankshaft Grinding/ RA Power Solutions

Price 1500 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Crankshaft Repair of MAN B&W 6L 16/24

Price 1000.0 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Allen Engine PVBCS12 F Crankshaft Repair in Gambia

Price 1500 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Crankshaft Repair Engine MAN 5L 16/24

Price 16000 USD ($) / Square Inch

Minimum Order Quantity : 1 Square Inch

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free