Crankshaft Repair with Damaged Radius Fillet

Price 1500 INR/ Square Inch

Crankshaft Repair with Damaged Radius Fillet Trade Information

- Minimum Order Quantity

- 1 , , Square Inch

- Supply Ability

- 1 , , Square Inch Per Day

- Delivery Time

- 2-3 Days

About Crankshaft Repair with Damaged Radius Fillet

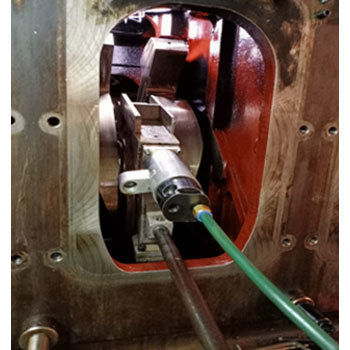

RA Power Solutions have been successfully undertaking onsite repair of crankpin/ Main Journal for the last 41 years. We have the facilities to undertake repair of crankshaft diameter ranging from 30 mm to 700 mm.

We have observed that due to accident the radius fillet of the crankpin and main journal gets damaged or worn out, In which condition it becomes difficult to undertake the grinding of the crankshaft as most of companies have the grinding tool which is placed on the radius fillet and undertakes the grinding by taking the reference of fillet radius.

In this situation the crankshaft repair companies either reject the crankshaft or recommend sending the crankshaft to a designated workshop for the repair.

We are the only company in the world which can undertake the grinding of crankpin having damaged radius fillet. We have the credit and experience of successfully undertaking the repair of crankshaft radius fillet of which is damaged or worn out.

Successful Repair of Crankshaft with damaged Fillet radius:

i) It is generally noticed that in case of seizure of bearing the bearing material gets embedded on the crankpin and the radius fillet of both the sides.

ii) Radius fillet gets damaged either during the failure of bearing as the bearing steel shell rubs with the radius fillet or the bearing material gets embedded on the radius fillet which while removing damages the radius fillet.

iii) Crankshaft repair companies take the reference of radius fillet for grinding purpose and are not able to undertake repair due to damage radius fillet.

iv) RA Power Solutions has the necessary tools, equipment and expertise for repair of crankshaft having damage radius fillet.

v) Don't reject or and send it to the workshop contact RA Power Power Solutions who will undertake the repair of damage radius fillet crankshaft onsite whether on vessel or for land base engines.

vi) Our technology and equipment is so advanced that the damaged radius fillet crankshaft repair is possible even while the vessel is sailing in a disturbed condition.

We have successfully executed damage radius crankshaft repair of MAN B&W, Yanmar, Daihatsu, Wartsila, Ruston & Hornsby Engine etc.

Precision Restorations for Critical Engine Components

Our Crankshaft Repair with Damaged Radius Fillet service focuses on meticulous radius fillet restoration for automotive engine crankshafts. Using controlled welding and precision machining, we repair cracks, pitting, and wear to restore crankshafts to OEM tolerances. This ensures optimal performance and prolongs the lifespan of your engine's most vital component.

Comprehensive Quality Assurance

Each repair undergoes magnetic particle inspection for crack detection and hardness testing to confirm material integrity. With surface finishes of Ra 0.2-0.4 m and post-repair heat treatment when required, you gain confidence in a reliable and durable repair. Our compliance with strict accuracy standards guarantees lasting results.

Flexible and Efficient Service Delivery

Offering both on-site and in-house repair, we accommodate various operational requirements across India. Typical lead times are just 5-10 working days, and our services come with a 6-12 month warranty under specified conditions. As a reputable exporter, manufacturer, and service provider, we ensure your crankshaft is expertly restored for continued use.

FAQ's of Crankshaft Repair with Damaged Radius Fillet:

Q: How is the damaged radius fillet on a crankshaft repaired?

A: The damaged fillet is restored using specialized welding to rebuild worn, pitted, or cracked areas, followed by precision machining to achieve OEM contours. This process ensures dimensional accuracy up to 0.01 mm and a surface finish of Ra 0.2-0.4 m. Post-repair inspections verify the integrity and hardness as per required standards.Q: What types of crankshaft damage can this service address?

A: This repair process is suitable for wear, pitting, and cracks specifically in the radius fillet areas of forged or case-hardened steel crankshafts. The service can accommodate shafts up to 2.5 meters in length and journals up to 300 mm diameter.Q: When should I consider radius fillet restoration for my crankshaft?

A: Radius fillet restoration should be considered when inspections reveal wear, cracks, or pitting that could compromise the crankshaft's durability or performance. Timely repair helps prevent further engine damage and extends the component's lifecycle.Q: Where can the crankshaft repair service be performed?

A: We offer both in-house and on-site repair solutions throughout India, providing flexibility to suit your operational needs, whether your crankshaft requires removal for shipping or rapid restoration at your location.Q: What is involved in the repair process after machining the fillet radius?

A: After welding and machining, the restored area is subject to magnetic particle inspection to detect any cracks, followed by hardness testing. Upon request, a heat treatment process can be performed to restore material hardness to OEM specifications.Q: How long does the crankshaft repair usually take?

A: A typical repair is completed within 5-10 working days, depending on the extent of the damage and service requirements, ensuring quick turnaround for minimal engine downtime.Q: What are the benefits of choosing this radius fillet repair service?

A: Benefits include adherence to OEM specifications, high machining accuracy, superior surface finish, thorough post-repair testing, fast turnaround, nationwide service flexibility, and warranty coverage for peace of mind.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Repairs & Maintenance Services Category

Allen Engine PVBCS12 F Crankshaft Repair in Gambia

Price 1500 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Onsite Crankshaft Repair

Price Range 260000.00 - 1600000.00 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Onsite Crankshaft Repair by Ra Power

Price 13000 INR / Number

Minimum Order Quantity : 1 Square Inch

Yanmar Diesel Generator Model no. 8N280L-EV Crankshaft Repair

Price 1500 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS