MAN 9 ASL 25/30 Crankshaft Repair/in situ Crankshaft Grinding RA Power Solutions

Price 1500 INR/ Square Inch

MOQ : 1 Square Inch

MAN 9 ASL 25/30 Crankshaft Repair/in situ Crankshaft Grinding RA Power Solutions Trade Information

- Minimum Order Quantity

- 1 Square Inch

- Supply Ability

- 1 Square Inch Per Day

- Delivery Time

- 2-3 Days

About MAN 9 ASL 25/30 Crankshaft Repair/in situ Crankshaft Grinding RA Power Solutions

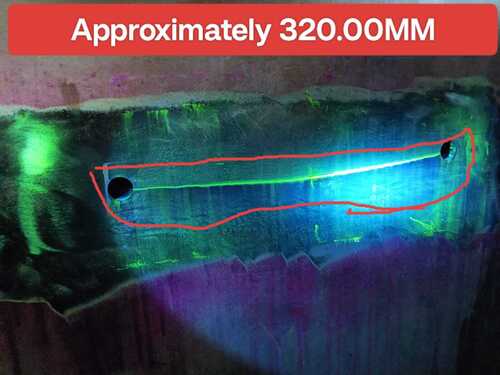

RA Power Solutions was informed by one of our client regarding failure of Crankpin no. 6 of AE#2 of MAN 9 ASL 25/30 Model Engine.

The Engine details are as following:

|

S. NO |

Crankshaft Details |

|

|

1 |

Engine Make |

MAN |

|

2 |

Engine Model |

9 ASL 25/30 |

|

3 |

Crank pin Diameter Standard |

195 mm |

|

4 |

Crankpin Bearing Width |

77 mm |

Efficient Onsite Crankshaft Grinding

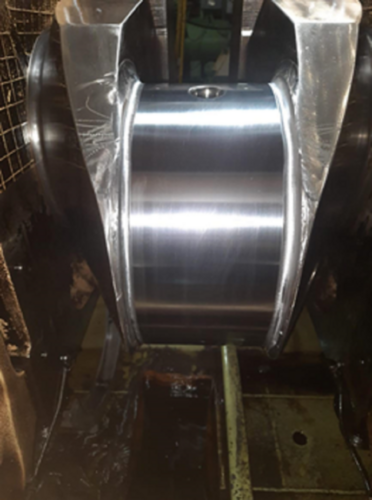

RA Power Solutions offers precision in situ crankshaft grinding services, enabling repairs to be completed at the client's site or onboard ships. Our advanced portable machines handle diameters from 30 mm to 700 mm and lengths up to 11 meters. This minimizes downtime significantly, as crankshafts remain installed during the repair, reducing associated removal and transport costs.

Comprehensive Defect Resolution & Alignment

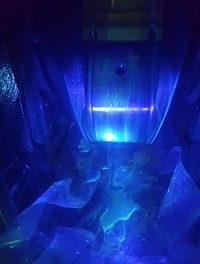

Our experienced technicians rectify various crankshaft defects, including cracks, damage, bearing failures, and pin journal issues. Post-repair, comprehensive alignment ensures reliable engine performance. Crack detection uses reliable Magnaflux/MPI techniques, safeguarding against future failures and ensuring structural integrity.

Global Emergency and Routine Services

As an exporter, manufacturer, service provider, and supplier based in India, RA Power Solutions delivers both emergency breakdown and scheduled crankshaft repairs globally. Our quick-response team and specialized in situ technology ensure minimal service interruption in marine, power plants, and industrial applications worldwide.

FAQ's of MAN 9 ASL 25/30 Crankshaft Repair/in situ Crankshaft Grinding RA Power Solutions:

Q: How is in situ crankshaft grinding performed for MAN 9 ASL 25/30 engines?

A: In situ crankshaft grinding involves bringing portable, high-precision equipment directly to the engine site. The process repairs crankpins or main journals up to 700 mm diameter and 11 meters in length, allowing restoration without disassembling or removing the crankshaft.Q: What types of crankshaft defects can RA Power Solutions repair onsite?

A: Our technicians can rectify cracks, surface damage, bearing failure scarring, and rebuild worn pin journals for steel and cast iron crankshafts. Crack detection is implemented using Magnaflux/MPI for thorough assessment before repairs.Q: When should crankshaft grinding services be considered?

A: Crankshaft grinding is recommended when journals show ovality, scoring, pitting, cracks, or taper misalignment-often after operational damage, bearing failure, or preventive maintenance shutdowns in marine, shipping, or power plant engines.Q: Where does RA Power Solutions provide in situ crankshaft repair services?

A: We offer our services worldwide, attending ships, industrial plants, and power stations at any location. Our portable equipment and experienced teams ensure onsite repairs anywhere, minimizing logistical challenges.Q: What are the benefits of choosing onsite crankshaft repair over traditional methods?

A: Onsite crankshaft repair eliminates the need to remove the shaft from the engine, drastically reducing downtime, transportation risk, and operational disruption. Our repairs restore original tolerances and surface finish (0.2 Ra), with no loss of material hardness.Q: How do you ensure the repaired crankshaft meets stringent tolerances and alignment?

A: Precision portable equipment achieves machining tolerances up to 0.01 mm. After repair, crankshaft alignment is verified, and surface roughness is finished to 0.2 Ra, ensuring the component performs reliably within OEM specifications.Q: Is emergency breakdown service available for critical repairs?

A: Yes, RA Power Solutions provides rapid-response emergency breakdown service worldwide, minimizing machine downtime by quickly mobilizing technicians and portable equipment to the site for immediate repair needs.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Crankshaft Repair Category

Crack Repair of A Press Frame-3500 Ton

Price 775.0 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Repair of Sulzer Engine 6ZAL 40S Crankshaft

Price 1600 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Wartsila 9L20 Crankshaft Repair in Madagascar, East Africa

Price 99998.0 INR / Number

Minimum Order Quantity : 1 Number

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS