Onsite Crankshaft Grinding Repair of MAN B&W 5L 16/24

Price 90.0 INR/ Number

Onsite Crankshaft Grinding Repair of MAN B&W 5L 16/24 Specification

- Product Type

- Onsite Crankshaft Grinding Repair of MAN B&W 5L 16/24

- General Use

- Industrial

- Material

- Stainless Steel

- Computerized

- No

- Voltage

- 220-440 Volt (v)

- Feature

- High Performance

- Color

- Grey

- Warranty

- 1 Year

Onsite Crankshaft Grinding Repair of MAN B&W 5L 16/24 Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 1 Number Per Day

- Delivery Time

- 2-3 Days

About Onsite Crankshaft Grinding Repair of MAN B&W 5L 16/24

Onsite grinding of crankshaftwas executed by RA Power Solutions Technicians of Auxiliary Engine Number #02 of MAN B&W 5L 16/24. The details of the engine and crankshaft are given below:

| S. No. | Crankpin Details | |

| 1. | Engine Make | MAN B&W |

| 2. | Engine Model | 5L 16/24 |

| 3. | Crankpin Diameter Standard | 130.00 MM |

| 4. | Crankpin Bearing Width | 56.00 MM |

| 5. | Place of Execution of Grinding of Crankpin | Kandla Port, India |

| 6. | Name of Shipping Company | Reputed Company from Dubai, UAE |

|

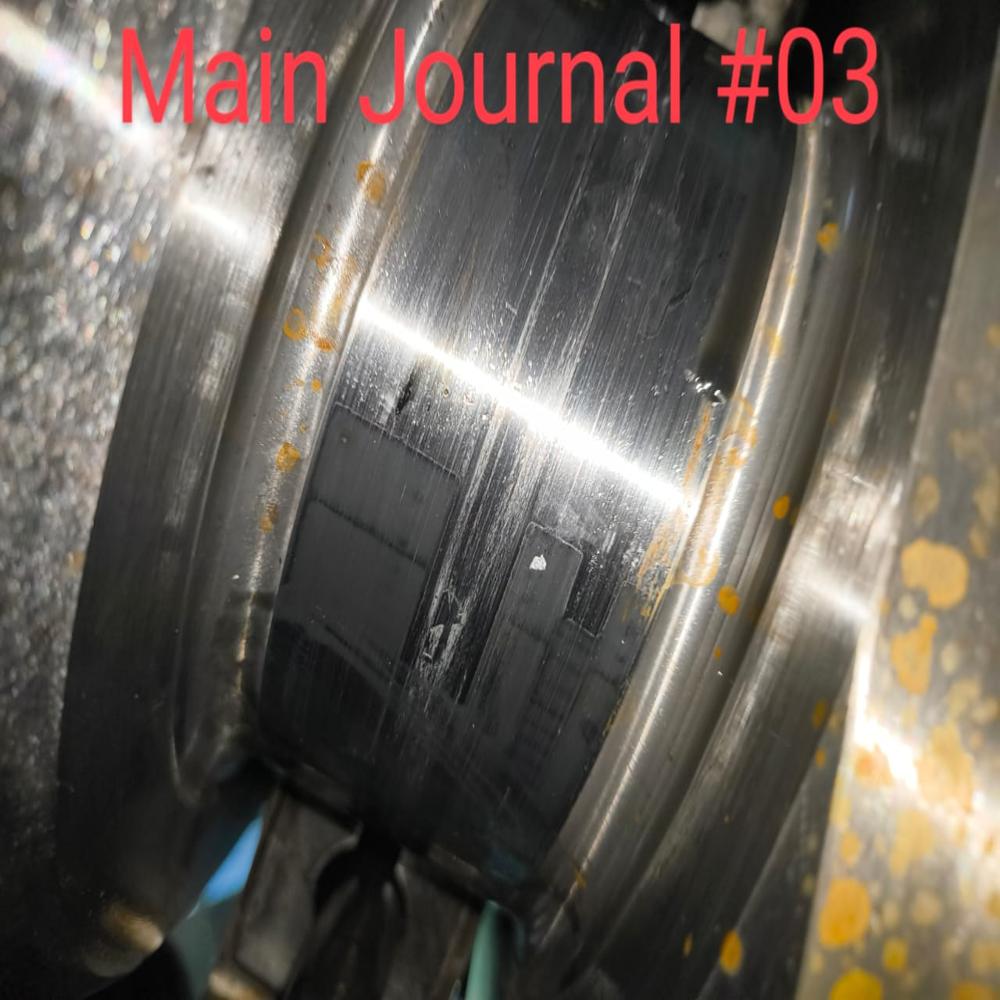

Crank Pin Before Grinding Crank Pin Before Grinding |

Crank Pin Having Dent Marks and Line Marks Crank Pin Having Dent Marks and Line Marks |

The Auxiliary engine number #02 of MAN B&W 5L 16/24 was stopped due to low air pressure, two of our technicians boarded the vessel and inspected the crankshaft. All Five (5) crankpins having a standard diameter of 130.00 MM had ovality ranging from 0.10 MM to 0.40 MM, which is considered to be on the higher side. The crankpins also had bearing line marks, rough surfaces, and localized damage, as the engine was operated in spite of the problem in the crankshaft.

The dimensional Report of crankpins is pasted below:

| SIZE OF CR PINS BEFORE REPAIR | |||||||||

| A | Aa | C | Cc | B | Bb | Min | STD & 1.5 &1.00 MM

U/S | Ovality | |

| CR-1 | 129.80 | 129.94 | 129.90 | 129.79 | 129.75 | 129.62 | 129.62 | 130.00 | 0.38MM |

| CR-2 | 128.45 | 128.42 | 128.46 | 128.40 | 128.47 | 128.45 | 128.40 | 128.50 | 0.10MM |

| CR-3 | 129.80 | 129.83 | 129.75 | 129.70 | 129.73 | 129.60 | 129.60 | 130.00 | 0.40MM |

| CR-4 | 129.87 | 129.85 | 129.85 | 129.77 | 129.91 | 129.90 | 129.75 | 130.00 | 0.25MM |

| CR-5 | 128.95 | 128.97 | 128.90 | 128.94 | 128.9 | 128.95 | 128.90 | 129.00 | 0.10MM |

The hardness and MPI for crack detection was conducted and no abnormality was observed. Technicians started onsite grinding of crankpins were ground ranging from 1.0 MM undersize to 1.50 MM.

|

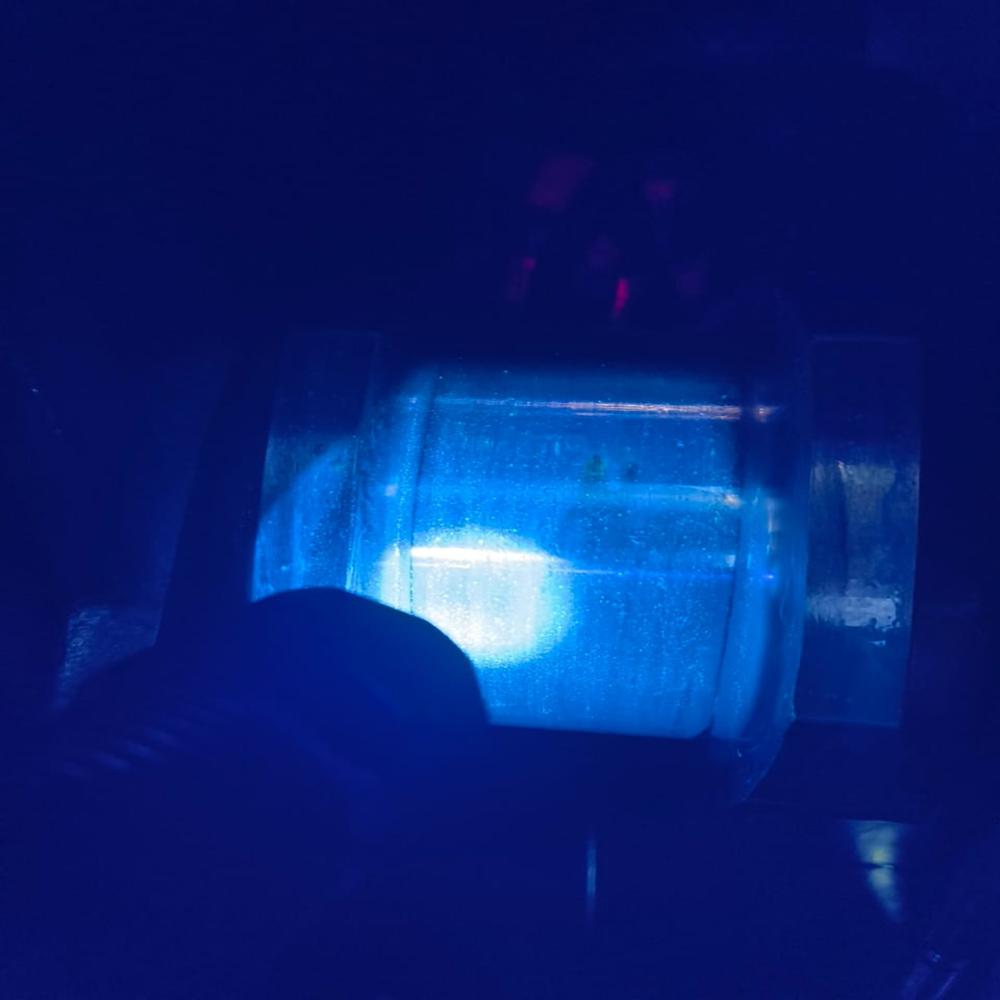

Hardness Test of Crank Pin MAN B&W 5L16/24 Engine Hardness Test of Crank Pin MAN B&W 5L16/24 Engine |

Inspection of Crankshaft of MAN B&W 5L16/24 Inspection of Crankshaft of MAN B&W 5L16/24 |

The main advantage ofonsite crankshaft grindingjobs executed byRA Power Solutionsis that the technicians and equipment are trained and designed to execute the job even while sailing of the vessel. There was absolutely no requirement of holding of the vessel. RA Power Solutions also supplied the undersizedcrankpin bearingsfor this engine and it was commissioned in a short notice.

RA Power Solutions with experience of more than 44 years extendsonsite crankshaft grinding servicesto leading shipping companies, power plants and heavy industries all over the world.

|

Onsite Crankshaft Grinding and Polishing Under Process Onsite Crankshaft Grinding and Polishing Under Process |

Crankshaft MAN B&W 5L16/24 Engine Under Repair Crankshaft MAN B&W 5L16/24 Engine Under Repair |

For more information regarding crankshaft grinding services, please contact us at rajshahani@rapowersolutions.com or info@rapowersolutions.com or call us at +91 9582647131 or +91 9810012383.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Crankshaft Grinding Category

Crankpin Grinding

Price 132000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, Mild Steel

Capacity : 30 to 150 mm (Range of Pin diameter grinding)

Control System : Manual

Model : CPG700

Crankshaft Grinding And Crankpin Machining

Price 134000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, Heavyduty cast iron body

Capacity : Custom (as per requirement)

Control System : Manual

Model : CGCP1600

Grinding of Crankshaft of MAN B&W

Price 132000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Cast Iron

Capacity : 15 Tons

Control System : PLC Control

Model : MAN B&W

Wartsila Crankshaft Grinding on Ship

Price 13500 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Material : Other, Alloy Steel

Capacity : Up to 800 mm stroke

Control System : Other, Manual Operation

Model : Wartsila OnShip Portable Grinder

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS