Repair of Crankshaft of MAN B&W Engine Model no. 5L 16/24

Price 1500 INR/ Square Inch

Repair of Crankshaft of MAN B&W Engine Model no. 5L 16/24 Trade Information

- Minimum Order Quantity

- 1 Square Inch

- Supply Ability

- 1 Square Inch Per Day

- Delivery Time

- 2-3 Days

About Repair of Crankshaft of MAN B&W Engine Model no. 5L 16/24

RA Power Solutions was informed about the repeated failure of crankpin bearings of MAN B&W 5L 16/24 by one of our client base in Dubai.

We deputed our technicians to Duqm port in Oman to undertake the inspection of the crankshaft and repair. The crankpin diameter and other details are mentioned below.

|

S. No |

Crankshaft Details |

|

|

1 |

Engine Make |

MAN B&W |

|

2 |

Engine Model |

5L 16/24 |

|

3 |

Crank pin Diameter Standard |

130 mm |

|

4 |

Crankpin Bearing Width |

56 mm |

|

5 |

Place of execution of crankshaft repair |

Duqm Port, Oman |

Inspection undertaken by RA Power Solutions of Crankshaft of MAN B&W Engine Model no.5L 16/24

i) The connecting rods of all the five crankpins were removed.

ii) On visual inspection the crankpin bearings were observed damaged with line marks.

iii) All crankpins were checked dimensionally for taper & ovality and to our surprise the ovality ranging from 0.13 mm to 0.20 mm was observed. Considering the standard size of crankpin as 130 mm minus 0.03 mm, It is very much on the higher side. Copy of Inspection report of crankpin is pasted below.

iv) All the crankpins were subject to checking of hardness by portable hardness tester and it was observed within limits.

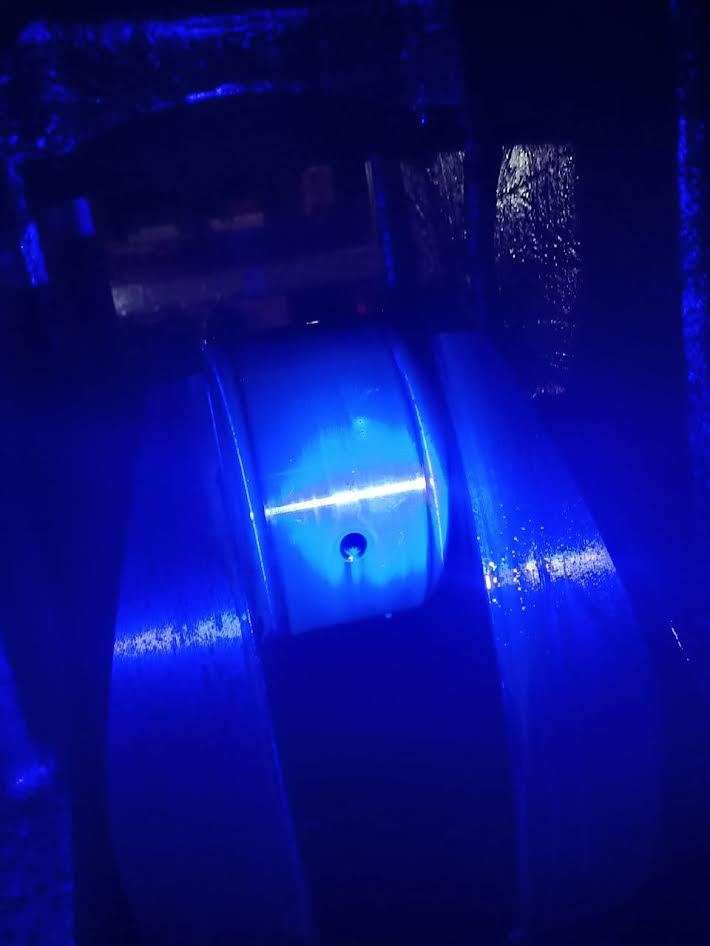

v) As a protocol the crankpins were also subject to crack detection test by MPI. No cracks or abnormality was observed.

vi) Bearing line marks and rough surface was observed on all crank pins journal.

Action taken by RA Power Solutions for successful repair of Crankshaft of MAN B&W Engine Model no. 5L 16/24

i) The five number crankpins were ground to the first step size of 0.5 mm maintaining the tolerances as per the manufacturer specifications.

ii) The final diameter was maintained between 129.47 mm and 129.50 mm.

iii) The radius and lubricating oil profile was maintained as per the original.

iv) Final readings of crankpins after grinding are pasted below.

Supply of undersize Bearing of MAN B&W Engine Model no. 5L 16/24

RA Power Solutions supplied 0.5 mm undersize bearings to the client.

The engine was commissioned in the presence of our technicians and performance was observed to be satisfactory.

Visit US:

Comprehensive Crankshaft Reconditioning Solutions

Our expert team employs advanced techniques for repairing forged steel crankshafts, ensuring optimal performance and longevity. We conduct thorough crack detection, precise grinding, polishing, straightening, and hardness restoration in accordance with original equipment manufacturer (OEM) specifications and class approvals. Each step guarantees consistent quality and safe operation in demanding environments.

Flexible On-Site and Workshop Services

We offer both on-site and workshop-based machining and reconditioning, adapting to your logistical requirements. This flexibility allows clients to minimize engine downtime and maintain operational efficiency, regardless of location. Our services are compatible with the MAN B&W 5L 16/24 and similar engine series, providing tailored solutions for every scenario.

Customization and Quality Assurance

Every repair can be customized according to unique crankshaft dimensions and the scope of repair needed. All work undergoes stringent testing to ensure full compliance with OEM standards and class approvals, delivering reliability and peace of mind for every project. We cater to single-unit orders and support large-scale operations.

FAQs of Repair of Crankshaft of MAN B&W Engine Model no. 5L 16/24:

Q: How is the crankshaft of a MAN B&W 5L 16/24 engine repaired?

A: The repair process involves on-site or workshop machining and reconditioning, which includes crack detection, grinding, polishing, straightening, restoring hardness, and comprehensive testing. Each step is performed according to OEM specifications and class approvals to ensure optimal reliability.Q: What materials are compatible with this crankshaft repair service?

A: Our repair solutions are specifically designed for forged steel crankshafts, ensuring full compatibility with the MAN B&W Model 5L 16/24 and similar engine models.Q: When should I consider crankshaft reconditioning for my MAN B&W engine?

A: It is advisable to seek reconditioning when there are signs of wear, cracks, imbalance, or loss of hardness. Regular inspections and addressing detected issues early help prevent severe engine damage and costly downtime.Q: Where can the crankshaft repair service be conducted?

A: We offer both on-site and workshop-based services, providing flexibility to complete repairs at your location or in our specialized workshop, depending on your operational needs and preferences.Q: What does the repair process involve for a MAN B&W 5L 16/24 crankshaft?

A: The process typically includes crack detection, precision grinding and polishing, straightening bent crankshafts, restoring hardness, and thorough testing. All work adheres to established OEM and class standards.Q: Is custom repair available for different crankshaft dimensions or engine models?

A: Yes, customization is available for dimensions and repair scope. We accommodate similar MAN B&W engine series and tailor our services to your specific requirements.Q: What benefits does this service offer to exporters, manufacturers, and service providers?

A: Our flexible approach, strict adherence to OEM specifications, and quick turnaround times minimize downtime, enhance reliability, and support efficient operations, benefiting exporters, manufacturers, service providers, suppliers, and traders alike.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Crankshaft Repair Category

Crankpin Repair of Deutz MWM TBG632V16 by RA power Solutions

Price 1500 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Wartsila vasa 32LN Engine Crankpin Repair

Price 1600 USD ($) / Number

Minimum Order Quantity : 1 Square Inch

Wartsila Engine Model no. 6R32, 4R32, 8R32, 9R32, 12V32LN, 16V32D, 16V32LN, W16V32, W18V32 Crankpin Repair | Crankshaft Grinding Onsite

Price 5000 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Onsite Crankshaft Grinding Machine

Price 300000 INR / Square Inch

Minimum Order Quantity : 1 , , Square Inch

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS