Wartsila vasa 32LN Engine Crankpin Repair

Price 1600 USD ($)/ Number

Wartsila vasa 32LN Engine Crankpin Repair Specification

- Maximum Journal Length

- Up to 700 mm

- Industry Served

- Marine, Power Plants, Industrial Engines

- Repair Method

- On-site Machining and Grinding

- Service Category

- Crankshaft Pin Journals Repair

- Post-Repair Hardness

- Maintained as per OEM Specification

- Crack Detection

- Performed during repair (MPI/NDT methods)

- Technician Expertise Level

- Experienced and OEM Certified Engineers

- Repair Location

- Onboard or In-Situ

- Repair Tolerance

- Up to 0.02 mm

- Minimum Order Quantity

- 1 Set

- Service Duration

- Depends on damage extent, typically 2-5 days

- Compatible Engine Model

- Wartsila vasa 32LN

- Product Name

- Wartsila vasa 32LN Engine Crankpin Repair

- Portable Equipment Used

- CNC On-site Machining Tools

- Material

- Alloy Steel

- Application

- Marine Diesel Engine Crankpin On-site Repair

- Surface Finish After Repair

- 0.2 Ra to 0.4 Ra

- Response Time

- Within 24 hours for service call

- Replacement Parts Provided

- Available on request

Wartsila vasa 32LN Engine Crankpin Repair Trade Information

- Minimum Order Quantity

- 1 Square Inch

- Supply Ability

- 1 Square Inch Per Day

- Delivery Time

- 2-3 Days

About Wartsila vasa 32LN Engine Crankpin Repair

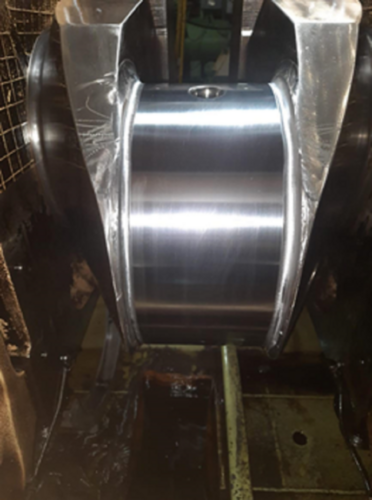

The video shows crank pin repair of Wartsila Vasa 32LN. The job of crankshaft repair of a Wartsila engine has been executed in a cement plant based in Nepal. The crankpin was damaged due to the seizure of the bearing. We regularly undertake onsite repair of crankshaft of all popular make of engines like Daihatsu, Yanmar, Wartsila, MAN B&W, Mirrlees Blackstone, Ruston, Allen, Caterpillar, SKL, Pielstick, Cummins, Deutz, etc.

RA Power Solutions is ISO 9001:2015 (Quality Management System) & ISO 14001:2015 (Environmental Management System) certified approved company.We have been regularly executing on-site crankshaft repairs and crankshaft grinding in Iraq, Iran, Dubai, Oman, Saudi Arabia, Qatar, Abu Dhabi, Sharjah, Ajman, Umm Al-Quwain, Fujairah, Bahrain, Kuwait, Antigua and Barbuda, Belize, Dominica, Dominican Republic, Malaysia, Indonesia, Madagascar, Vietnam, Grenada, Guyana, Haiti, Jamaica, Saint Kitts and Nevis, Saint Lucia, South Korea, Saint Vincent and the Grenadines, Trinidad, and Tobago, etc.

Precision Engine Repair for Critical Applications

Our crankpin repair service for the Wartsila vasa 32LN engine leverages state-of-the-art CNC on-site machining equipment to ensure precise restoration of your crankshaft's integrity. With an industry-leading response time and adherence to OEM hardness and surface finish, we minimize downtime while maximizing reliability and operational lifespan in demanding marine and power plant environments.

OEM Certified Engineering Expertise

Repairs are carried out by technicians with extensive experience and OEM certification. This guarantees that all work performed not only meets but often exceeds industry quality standards. Thorough crack detection and post-repair validation ensure your engine's crankpin operates with original efficiency and safety.

FAQ's of Wartsila vasa 32LN Engine Crankpin Repair:

Q: How is the crankpin repair for the Wartsila vasa 32LN engine performed on-site?

A: Repairs are executed with portable CNC machining and grinding tools operated by OEM-certified engineers. The process includes crack detection (MPI/NDT methods), precision machining, and final surface finishing to OEM specifications-all conducted onboard or in-situ at your facility.Q: What is the typical response time for a crankpin repair service call?

A: We guarantee a rapid response, with a technician available within 24 hours of your service call to assess and initiate the repair process.Q: When should crankpin repair be considered for my Wartsila vasa 32LN engine?

A: Repair should be considered at the first signs of crankpin wear, scoring, cracking, or abnormal vibration identified during routine maintenance or after an operational incident. Early intervention prevents further engine damage and costly downtime.Q: Where is the repair service available, and what engines are compatible?

A: Our repair service is available throughout India and supports the Wartsila vasa 32LN engine model. Repairs can be conducted onboard vessels, in power plants, or at industrial sites, ensuring minimal equipment transportation.Q: What is the repair tolerance and surface finish achieved after crankpin machining?

A: Post-repair, the crankpin journal achieves a dimensional tolerance up to 0.02 mm and a surface finish between 0.2 Ra and 0.4 Ra, conforming to Wartsila OEM standards for durability and performance.Q: How do you ensure crankpin hardness and structural integrity after repair?

A: Hardness is strictly maintained as per OEM specifications through controlled machining and finishing processes. Crack detection using MPI/NDT is performed during repair to validate structural integrity.Q: What are the main benefits of choosing this on-site repair service?

A: You benefit from minimized downtime, preservation of original engine components, certified engineering expertise, and strict adherence to OEM tolerances, enhancing engine reliability and reducing lifecycle costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Crankshaft Repair Category

Yanmar Diesel Generator Model no. 8N280L-EV Crankshaft Repair

Price 1500 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Repair of Sulzer Engine 6ZAL 40S Crankshaft

Price 1600 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Wartsila Engine 8L32 Crankshaft Repair

Price 1600 USD ($) / Number

Minimum Order Quantity : 1 Number

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS