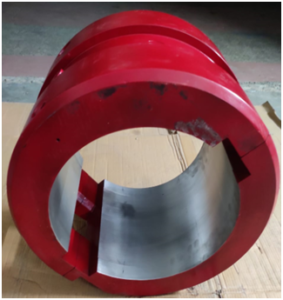

White Metal Babbitt Bearing

Price 3000-90000 USD ($)/ Piece

White Metal Babbitt Bearing Specification

- Lubrication Type

- Oil Lubrication

- Cage Material

- Steel / Brass

- Precision Rating

- ISO Standards

- Thickness

- Standard/Custom

- Retainer

- With Retainer

- Inside Diameter

- Custom

- Bearing Type

- White Metal Babbitt Bearing

- Material

- White Metal (Babbitt) Alloy

- Structure

- Split

- Seals Type

- Open

- Number Of Rows

- Single

- Bore Size

- Customized as per Requirement

- Outside Diameter

- Customized

- Limiting Speed

- Up to 1200 RPM

- Load Capacity

- High Load Bearing

- Application

- Industrial machinery, Turbines, Pumps, Electric Motors

- Temperature Range

- -20°C to +150°C

- Manufacturing Process

- Centrifugal or Static Casting

- Hardness

- Typically 22-30 HRC

- Mounting

- Flange / Foot Mounted Options

- Customization

- Available as per drawing or sample

- Replaceable Liner

- Available

- Corrosion Resistance

- Yes

- Surface Finish

- Machined and Polished

- Compliance

- Meets ASTMB23, IS:25 & DIN Standard specs

White Metal Babbitt Bearing Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 1 , , Piece Per Day

- Delivery Time

- 2-3 Days

- Certifications

- ISO 9001:2015 SEPC

About White Metal Babbitt Bearing

White Metal Babbitt Bearing

RA Power Solutions engineering department develops a drawing of the damaged or worn out bearing based on the dimensions which can be drawn from the old worn out or damaged bearings provided by the client. The dimensions which are not clear due to damage and old worn out bearings are incorporated in drawing based on our experience of four decades in design and development of bearing. We develop and manufacture the white metal Babbitt bearing based on the old bearing with 100%guarantee.

Exceptional Performance and Durability

Our White Metal Babbitt Bearings deliver high load-bearing capacity and superior corrosion resistance, ensuring long-term reliability in industrial machinery and rotating equipment across varied temperature conditions. The split structure and replaceable liner enhance maintenance efficiency, minimizing downtime.

Customization to Meet Your Needs

Whether you require specific bore sizes, mounting options, or thickness, these bearings can be tailored as per your drawing or sample. Options for cage material (steel or brass), lubrication (oil type), and sealing (open type) make them ideal for specialized operations in turbines, pumps, and electric motors.

FAQ's of White Metal Babbitt Bearing:

Q: How are White Metal Babbitt Bearings installed in industrial machinery?

A: These bearings can be mounted using either flange or foot mounting options, ensuring compatibility with a wide range of equipment. Installation is straightforward, especially with the split structure that allows easy assembly and replacement.Q: What applications are ideal for White Metal Babbitt Bearings?

A: They are best suited for industrial machinery, turbines, pumps, and electric motors due to their high load-bearing capacity, corrosion resistance, and ability to function efficiently across a wide temperature range.Q: When should the replaceable liner be considered for maintenance?

A: A replaceable liner is recommended during regular maintenance or whenever significant wear is noticed, ensuring the bearing's longevity and reducing downtime for equipment.Q: Where are these bearings primarily used?

A: Our White Metal Babbitt Bearings are widely utilized in manufacturing units, power generation facilities, and pump stations throughout India and globally, wherever robust and high-precision bearings are required.Q: What manufacturing processes are used for these bearings?

A: The bearings are produced through centrifugal or static casting methods, providing optimal structure and durability. Machined and polished surfaces guarantee precision and reliability.Q: How does the corrosion resistance benefit industrial operations?

A: Corrosion resistance prolongs the service life of bearings, even when exposed to moisture or chemicals, reducing replacement frequency and maintenance costs for operators.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in White Metal Bearing Category

Babbitt White Metal Mearing Repair

Price 3400 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Precision Rating : ISO 9001:2015

Material : Other, White Metal/Babbitt Alloy

Thickness : As per Specification

Number Of Rows : Other, Single

White Metal Bearings

Price 3100 USD ($) / Piece

Minimum Order Quantity : 1 , , Piece

Precision Rating : Industry Standard / Custom tolerances

Material : Other, White Metal (Babbitt Alloy)

Thickness : Varies as per design

Number Of Rows : Other, Single or MultiRow

Wartsila Bearing Rebabbitting

Price 10000 INR / Number

Minimum Order Quantity : 1 Number

Precision Rating : ISO

Material : Other, Steel Backed With White Metal (Babbitt)

Thickness : Custom as per requirement

Number Of Rows : Other, Single

Babbitt White Metal Ingots

Price 3300-70000 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Precision Rating : Industrial Grade

Material : Other, Babbitt Alloy (Tin/LeadBased)

Thickness : Varies

Number Of Rows : Other, Single

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS