Babbitt bearning Alloy Ingots Manufacturer

Babbitt bearning Alloy Ingots Manufacturer Specification

- Inside Diameter

- Customizable

- Thickness

- Customizable

- Lubrication Type

- Oil or Grease

- Precision Rating

- Industrial Grade

- Bearing Type

- Babbitt Bearing Alloy

- Material

- Babbitt Alloy (Tin- or Lead-based)

- Structure

- Solid Ingot

- Number Of Rows

- Single

- Bore Size

- Customizable

- Outside Diameter

- Customizable

- Load Capacity

- High

- Grade Available

- Grade 1, Grade 2, Grade 3 Babbitt Alloys

- Corrosion Resistance

- Excellent

- Surface Finish

- Smooth

- Application

- Hydrodynamic Bearing Linings, Heavy Industrial Machinery

- Density

- 7.37.5 g/cm

- Color

- Silver / Grey

- Melting Point

- 240C - 350C

- Standard

- ASTM B23, IS 25/50/75 Types

- Hardness

- HB 2236 (Depending on Grade)

- Shape

- Rectangular Ingots

- Packaging Type

- Ingot Form, Wooden Box

Babbitt bearning Alloy Ingots Manufacturer Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 1 Number Per Day

- Delivery Time

- 2-3 Days

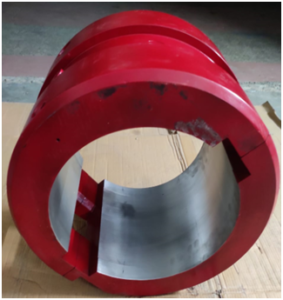

About Babbitt bearning Alloy Ingots Manufacturer

With experience of forty-three years in the field of manufacturing of babbitt white metal bearings for Diesel engines, turbine, etc up to 1500 mm we have proven that the babbitt white metal ingots which are manufactured by us are of international standard as the same babbitt white metal is used for manufacturing of bearing by RA Power Solutions for in house production performance of which has been proved.

RA Power Solutions is ISO 9001:2015 (Quality Management System) & ISO 14001:2015 (Environmental Management System) certified approved company.

We have been regularly exporting the babbitt white metal ingots to various companies in USA. The most popular compositions ofBabbitt white metal ingotssupplied by us is as following:

| S. No. | TECHNICAL SPECIFICATION |

| 1. | WHITE METAL: POWER BABBIT, COMPOSITION: Sn = 83.2% Sb = 8.33 Cu = 8.33 Ni = 0.13% |

| 2. | WHITE METAL: ACCORDING TO GERMAN STANDARD: ALLOY "V 738" Sn = 80.00% Sb = 12 0 ' Cu = 8.00 |

We have the following Babbitt Bearing ingots in regular production lines and can be supplied in a short time.

Engineered for Precision and Durability

Our Babbitt bearing alloys are designed to deliver high load capacity, excellent lubrication, and superior corrosion resistance. Their customizable shapes and sizes ensure a perfect fit for all types of hydrodynamic bearings in heavy industrial applications. Each ingot undergoes strict quality control to guarantee performance and durability.

Certified to International Standards

All our Babbitt alloy ingots conform to the latest ASTM B23 and IS 25/50/75 specifications. This assurance of compliance with both domestic and global benchmarks underscores our commitment to product reliability, safety, and compatibility in varied industrial environments.

Versatile Applications in Heavy Industry

Our ingots are ideally suited for the manufacture of bearing linings in turbines, compressors, generators, pumps, and more. The material's adaptable properties, like customizable bore size and thickness, make it indispensable in numerous industrial sectors, including manufacturing, heavy machinery, and power generation.

FAQ's of Babbitt bearning Alloy Ingots Manufacturer:

Q: How are Babbitt bearing alloy ingots used in heavy industrial applications?

A: Babbitt bearing alloy ingots are primarily used for lining hydrodynamic bearings that support rotating shafts in heavy industrial machinery. They provide a low-friction, high-load capacity surface to enhance equipment efficiency and longevity.Q: What is the manufacturing process for your Babbitt alloy ingots?

A: Our Babbitt alloy ingots are produced using advanced metallurgy, melting high-purity tin or lead with alloying elements at controlled temperatures (240C-350C), cast into rectangular ingots, and finished for a smooth, solid, corrosion-resistant structure.Q: When should I choose Grade 1, Grade 2, or Grade 3 Babbitt alloy?

A: The choice between Grade 1, Grade 2, and Grade 3 depends on your application's load, speed, and temperature requirements. Grade 1 is best for high-speed, low-load applications, while Grade 3 excels in high-load, low-speed environments. Grade 2 offers balanced properties for medium-duty use.Q: Where do you export and supply Babbitt alloy ingots?

A: We are a reputable exporter, manufacturer, and supplier, servicing clients across India and select international markets. Our products are packaged in sturdy wooden boxes to ensure they arrive in excellent condition wherever needed.Q: What are the benefits of using Babbitt alloy for bearing linings?

A: Babbitt alloys provide excellent corrosion resistance, superior lubrication (with oil or grease), and a smooth surface finish. They are customizable for various dimensions, ensuring optimal fit, performance, and prolonged bearing life.Q: How do you ensure the corrosion resistance of your Babbitt ingots?

A: Our ingots are engineered with specific alloy compositions and undergo strict quality checks to produce a corrosion-resistant surface, maintaining performance even in harsh industrial environments.Q: What packaging options are available for your Babbitt alloy ingots?

A: We package our Babbitt alloy ingots in rectangular form, securely placed in wooden boxes for safe transportation and storage, preserving the surface finish and preventing contamination during handling.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in White Metal Bearing Category

Rebabbitting of White Metal Bearings Manufacturer For 43 Years

Price 16000 USD ($) / Number

Minimum Order Quantity : 1 Number

Number Of Rows : Other, Single and Double Row (as per requirement)

Lubrication Type : Other, Oil or Grease

Material : Other, HighGrade White Metal (Babbitt) Alloy

Outside Diameter : Upto 1500 mm or as specified

Trimetal Bearing

Price 3100 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Number Of Rows : Single Row

Lubrication Type : Other, Oil

Material : Other, Steel/Copper/Lead Bronze

Outside Diameter : 70 mm

White Metal Bearings

Price 3100 USD ($) / Piece

Minimum Order Quantity : 1 , , Piece

Number Of Rows : Other, Single or MultiRow

Lubrication Type : Other, Oil Lubricated (Hydrodynamic)

Material : Other, White Metal (Babbitt Alloy)

Outside Diameter : Customized as per application

Babbitt White Metal Mearing Repair

Price 3400 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Number Of Rows : Other, Single

Lubrication Type : Other, Oil Lubricated

Material : Other, White Metal/Babbitt Alloy

Outside Diameter : Standard & Customized

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS