Crack Repair of A Press Frame-3500 Ton

Price 775.0 INR/ Square Inch

MOQ : 1 Square Inch

Crack Repair of A Press Frame-3500 Ton Specification

- Temperature Resistance

- Up to 350°C

- Surface Treatment

- Post-Weld Heat Treatment

- Inspection Method

- Ultrasonic and Visual Testing

- Load Test Upon Completion

- Yes

- Frame Capacity

- 3500 Ton

- Service Life Extension

- 5-10 Years After Repair

- Structure Type

- Heavy-Duty Industrial Press

- Application

- Crack Repair of Press Frame

- Repair Technique

- Welding and Reinforcement

- Repair Location

- Critical Stress Zones of Frame

- Frame Material

- High-Strength Steel

Crack Repair of A Press Frame-3500 Ton Trade Information

- Minimum Order Quantity

- 1 Square Inch

- Supply Ability

- 1 Square Inch Per Day

- Delivery Time

- 2-3 Days

About Crack Repair of A Press Frame-3500 Ton

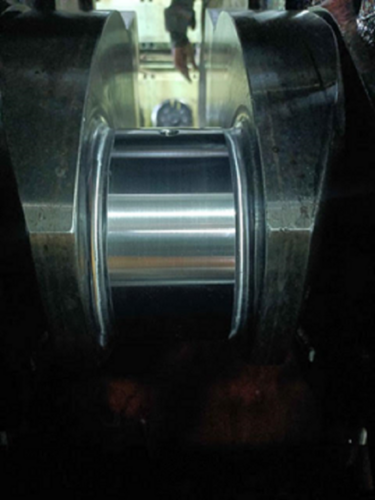

RA Power Solutionswas approached by a leading automobile manufacturing company based in North India to execute the repair of a damaged main frame body of 3500 Ton Press, supplied, installed, and maintained by a renowned Japanese company. RA Power Solutions team of engineers visited the plant during the shutdown and following was observed.

- The main frame of the 3500 Ton Press, which developed crack was the backbone of the plant as the complete body of the vehicles including doors/bonnet etc were formed on the press.

- The company was asked to disassemble all the parts, adjacent to the area where the crack was developed.

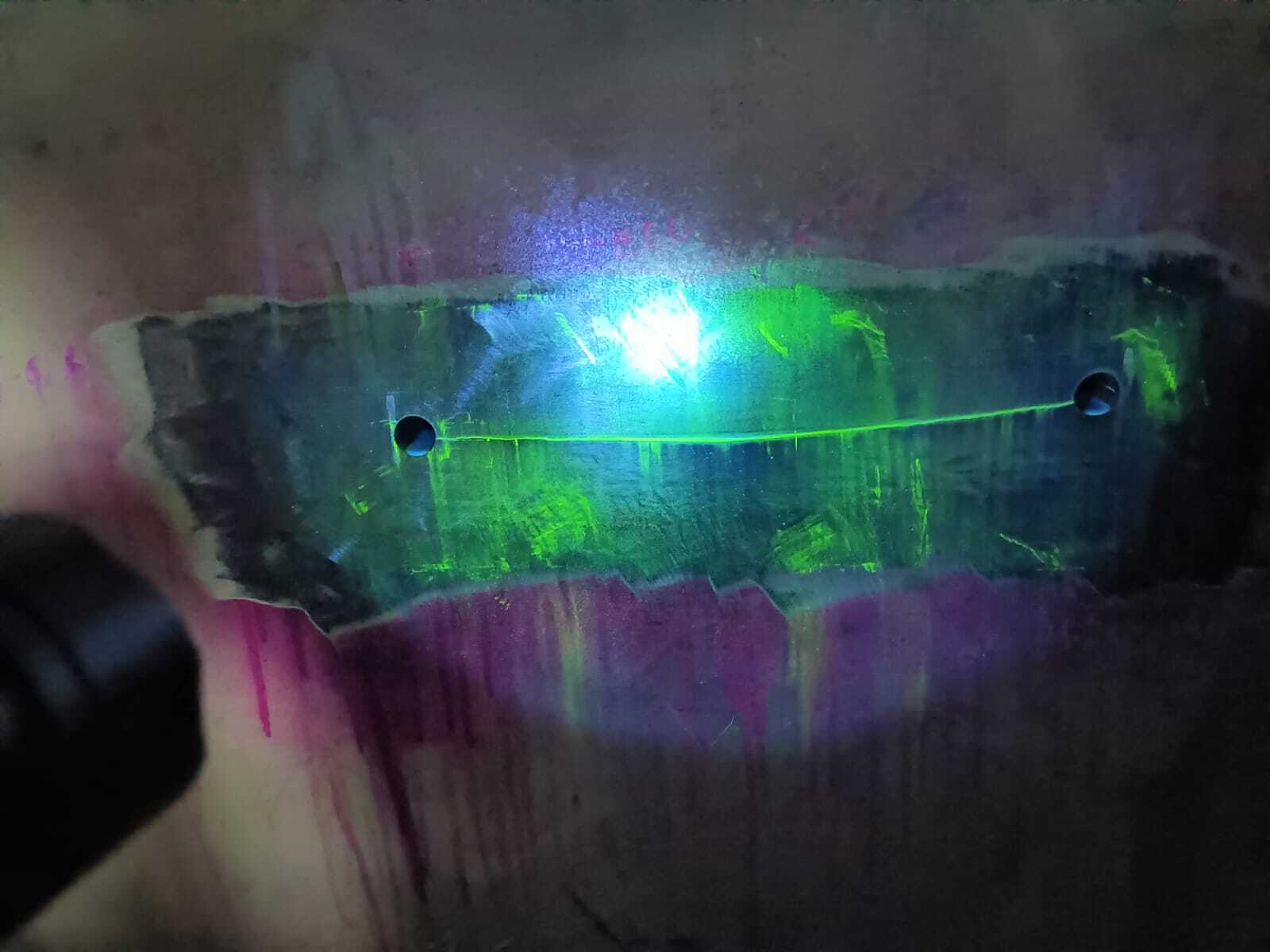

- The crack area of the press was thoroughly cleaned. Paint and red oxide were completely removed by the chemicals.

- The hardness test of the crack area of the press was undertaken.

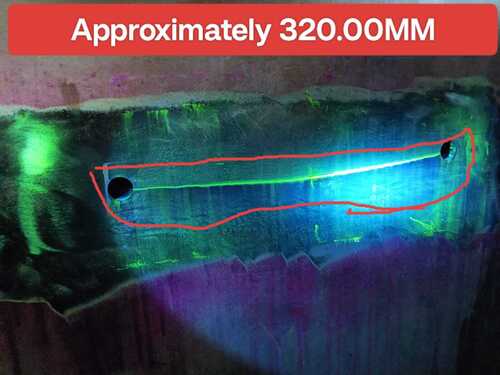

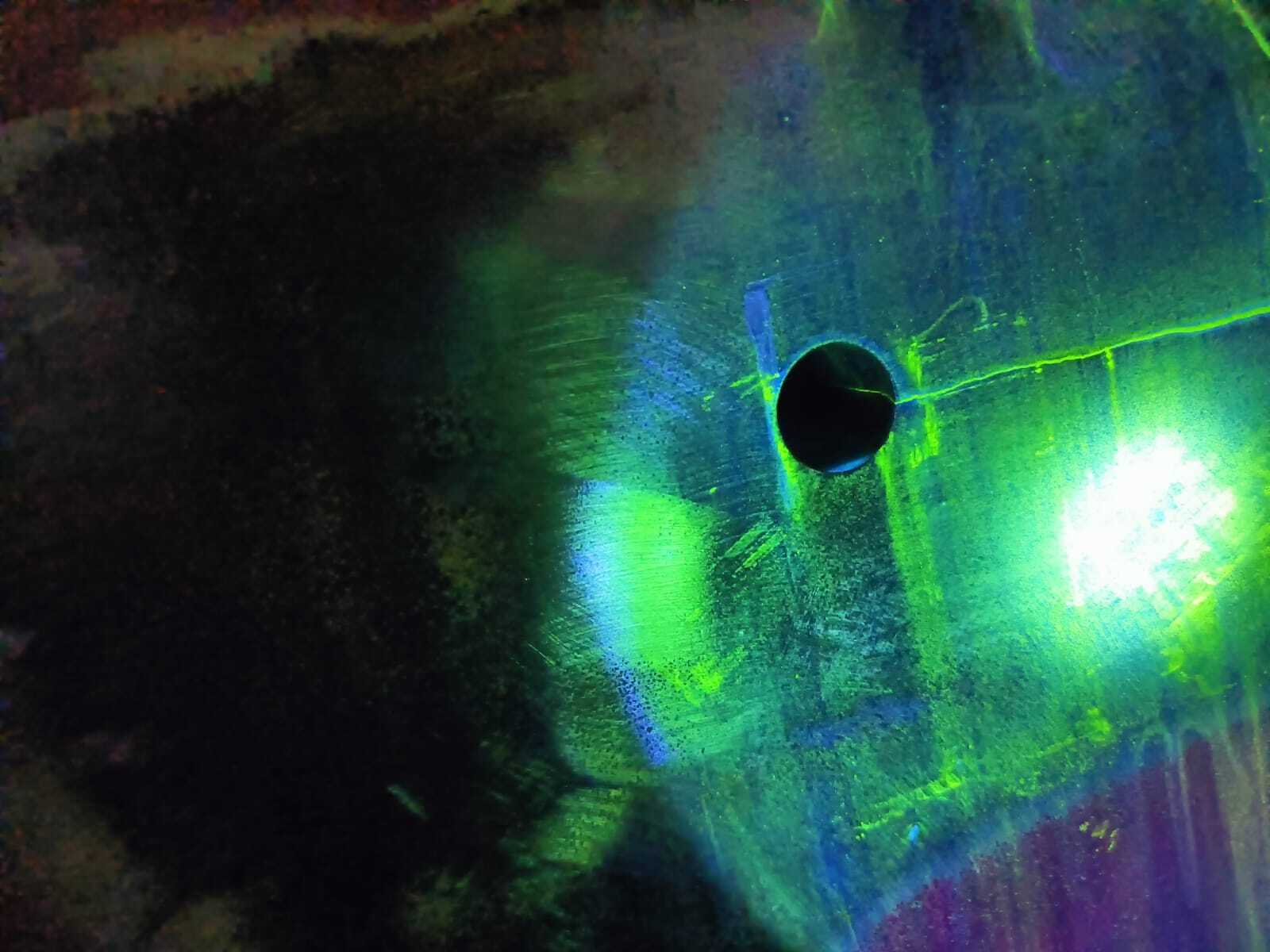

- The MPI test was done on the crack area where a crack having a horizontal profile measuring 400 MM was observed.

- The crack was through the complete width of the frame plate having thickness of 40 MM.

All the technical parameters including load characteristics of 3500 Ton Press were studied by the RA Power Solutions engineers and it was decided to go ahead with therepair of crack by metal stitchingand metal locking process.

Precision Repair for Press Frame Longevity

Welding and reinforcement of heavy-duty press frames reinstate the strength and safety essential for high-pressure operations. Our targeted repairs in critical stress zones employ ultrasonic and visual inspections, ensuring faults are accurately diagnosed and addressed. Every repair is finalized with post-weld heat treatment and a rigorous load test, affirming the frame's readiness for continued heavy industrial use.

Comprehensive Service from Diagnosis to Certification

Our crack repair process encompasses detailed inspection, precise crack removal, advanced welding, reinforcement, and surface treatment. By following industry-leading standards, we extend the life of press frames by several years and optimize operational efficiency, all while ensuring compliance with stringent safety requirements.

FAQ's of Crack Repair of A Press Frame-3500 Ton:

Q: How is the crack repair performed on the 3500-ton press frame?

A: Crack repair is executed through advanced welding and the addition of reinforcements at critical stress zones. The process includes thorough crack removal, precision welding, application of reinforcing elements, post-weld heat treatment, and a final load test for validation.Q: What inspection methods are used before and after repair?

A: Both ultrasonic and visual testing are employed to detect and assess cracks before repair, and to verify the integrity of the welds and reinforcements after the repair process is completed.Q: When should crack repair be conducted on an industrial press frame?

A: Crack repair should be undertaken as soon as any structural flaws are identified during routine maintenance or scheduled inspections, especially in critical stress areas to prevent operational failure.Q: Where are the repairs targeted within the press frame?

A: Repairs are focused on the critical stress zones of the frame, where cracks are most likely to compromise structural performance and safety.Q: What is the benefit of post-weld heat treatment in this process?

A: Post-weld heat treatment relieves residual stresses from welding, enhances metallurgical properties, and prevents further cracking, resulting in a more durable and reliable repair.Q: How does this service extend the life of the press frame?

A: By addressing existing cracks and reinforcing vulnerable zones using advanced techniques, the repair service prolongs the operational life of the frame by 5 to 10 years, even under demanding industrial conditions.Q: Who provides these crack repair services in India?

A: We are a prominent exporter, manufacturer, service provider, supplier, and trader based in India, specializing in the crack repair of heavy-duty industrial press frames.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Crankshaft Repair Category

Crankshaft Repair/ Crankshaft Machining Services in Ecuador

Price 1500 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Crankshaft Repair Engine MAN 5L 16/24

Price 16000 USD ($) / Square Inch

Minimum Order Quantity : 1 Square Inch

Crankshaft Repair of MAN B&W 6L 16/24

Price 1000.0 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Onsite Crankshaft Grinding Machine

Price 300000 INR / Square Inch

Minimum Order Quantity : 1 , , Square Inch

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS