Crankpin Repair of Deutz MWM TBG632V16 by RA power Solutions

Price 1500 INR/ Square Inch

Crankpin Repair of Deutz MWM TBG632V16 by RA power Solutions Trade Information

- Minimum Order Quantity

- 1 Square Inch

- Supply Ability

- 1 Square Inch Per Day

- Delivery Time

- 2-3 Days

About Crankpin Repair of Deutz MWM TBG632V16 by RA power Solutions

RA Power Solutions was invited by a company based in Hamedan city of Iran to attend to the problem of crankshaft of their Gas Engine Deutz MWM TBG632V16.

Observations & action taken for crankpin repair of Deutz MWM TBG632V16

i) Our two technicians along with a portable onsite crankshaft grinding machine visited Iran in short notice.

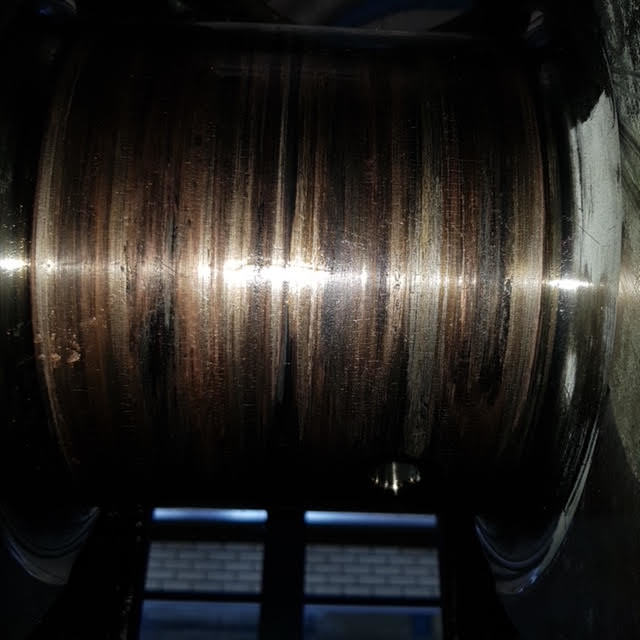

ii) On dimensional inspection of the crankpin it was observed that only one number of crankpins was damaged and having an ovality of 0.2 mm.

iii) All other crankpins were also checked for dimensional and were found within a limit.

iv) As a matter of protocol the damaged crankpin was also subject to crack detection by MPI.

v) The hardness was also checked and no abnormality was observed.

vi) The deflection of the complete crankshaft of Deutz MWM TBG632V16 engine was checked and was observed within limits.

vii) The damaged crankpin was ground to the undersize of 0.5 mm maintaining the tolerance strictly as per the manufacturer manual.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Crankshaft Repair Category

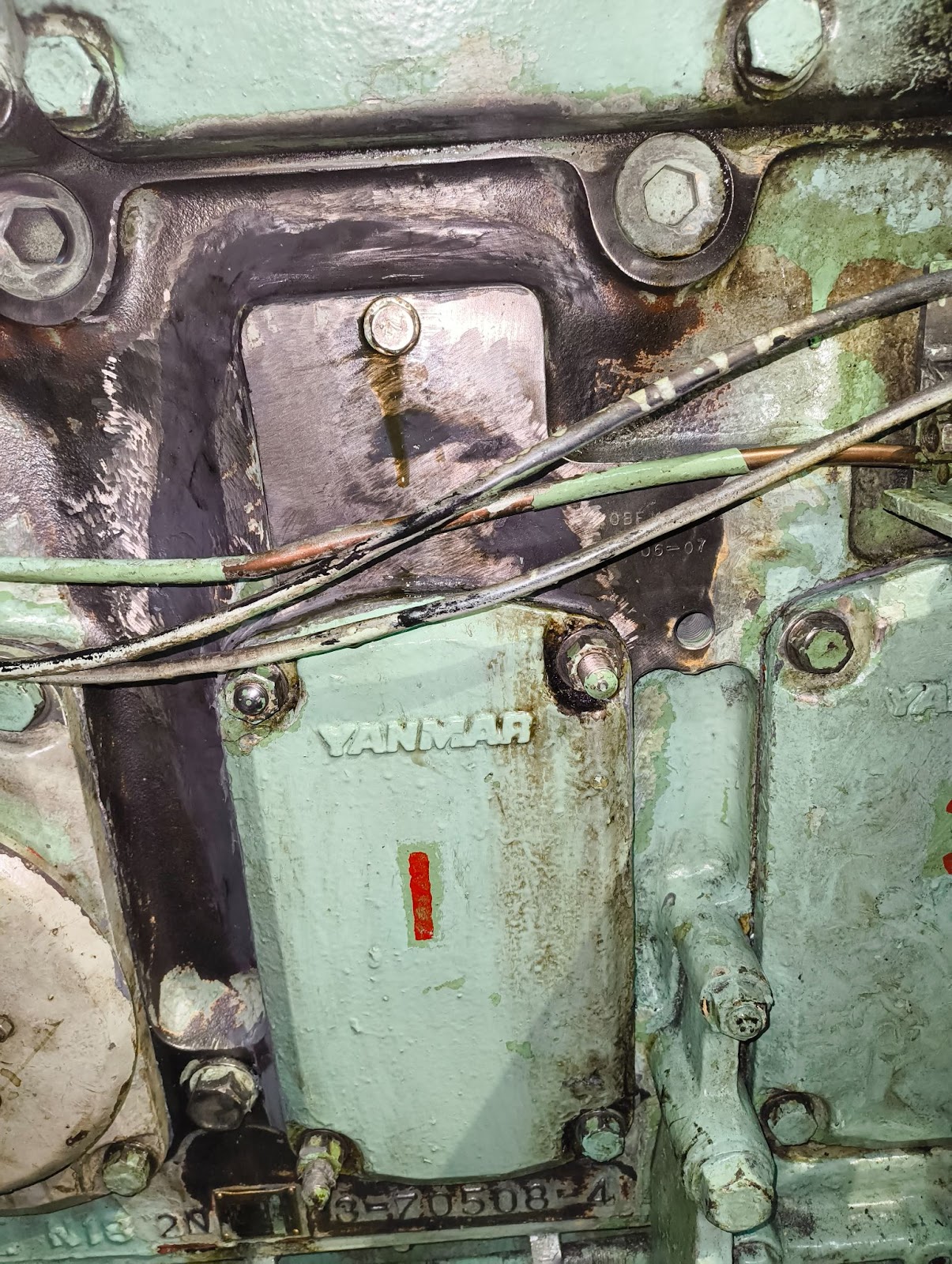

Yanmar S185L-ST Crankshaft Repair

Price 1000.0 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

YANMAR 6N18L-SV Auxiliary Engine Crankshaft

Price 1000.0 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Crankshaft Repair of MAN B&W 6L 16/24

Price 1000.0 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS