Man B&W 5T23LH, 6L23/30, 9L 27/38, 7L 32/40, 7L 16/24, 9L28/32, 9L25/30, 6L 52/55B Crankshaft grinding onsite

Price 1500 USD ($)/ Number

Man B&W 5T23LH, 6L23/30, 9L 27/38, 7L 32/40, 7L 16/24, 9L28/32, 9L25/30, 6L 52/55B Crankshaft grinding onsite Specification

- Engine Type

- MAN B&W 5T23LH, 6L23/30, 9L27/38, 7L32/40, 7L16/24, 9L28/32, 9L25/30, 6L52/55B

- Thickness

- As per OEM standard

- Inner Diameter

- As per OEM drawing

- Usage

- Restoration and repair of crankshafts onsite

- Fuel Type

- Diesel

- Thread size

- N/A (Not applicable for crankshaft)

- Other Features

- Onsite grinding, High precision, Surface finishing as per OEM

- Cooling System

- Water-cooled

- Finish Type

- Surface Hardened, Precision Ground

- Mount Type

- Engine block mounted

- Load Capacity

- Designed for high-load marine diesel engines

- Material Grade

- EN24, EN8, or equivalent high-strength alloy steel

- Outlet Diameter

- As per OEM drawing

- Power Output

- Engine specific (varies by model)

- Product Type

- Engine Spare Parts

- Parts Name

- Crankshaft

- Material

- Forged steel alloy

- Application

- Marine Engines, Power Plants

- OE Number

- As per engine model specification

- Size

- Standard and customized sizes as per model

- Dimensions

- Customized as per engine model

- Weight

- Varies as per engine model (up to 2500 kg)

- Power

- Engine dependent (up to 7600 kW)

- Stroke

- As per engine model (up to 650 mm)

- Head

- N/A (Not applicable for crankshaft)

- Inspection

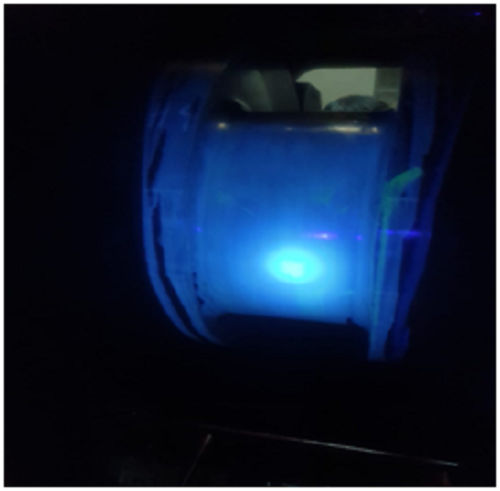

- Crankshaft crack detection and dimensional check before/after grinding

- Standards Followed

- Complies with MAN B&W OEM standards

- Hardness After Repair

- 54-58 HRC (as per OEM)

- Surface Roughness

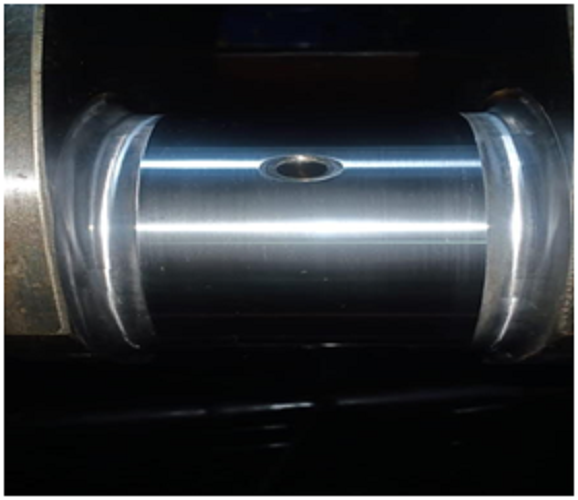

- Ra 0.2 to 0.4 µm

- Applicable Engine Models

- MAN B&W 5T23LH, 6L23/30, 9L27/38, 7L32/40, 7L16/24, 9L28/32, 9L25/30, 6L52/55B

- Minimum Journal Diameter Possible

- 85 mm

- Repair Method

- Grinding and polishing

- Maximum Journal Diameter Possible

- 550 mm

- Concentricity

- Within 0.02 mm

- Service Location

- Onsite (ship/vessel or powerplant)

- Machining Accuracy

- Up to 0.01 mm

- Service Team

- Trained and certified technical engineers

- OEM Compatibility

- 100% compatible with MAN B&W engine models listed

Man B&W 5T23LH, 6L23/30, 9L 27/38, 7L 32/40, 7L 16/24, 9L28/32, 9L25/30, 6L 52/55B Crankshaft grinding onsite Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 1 Number Per Day

- Delivery Time

- 2-3 Days

About Man B&W 5T23LH, 6L23/30, 9L 27/38, 7L 32/40, 7L 16/24, 9L28/32, 9L25/30, 6L 52/55B Crankshaft grinding onsite

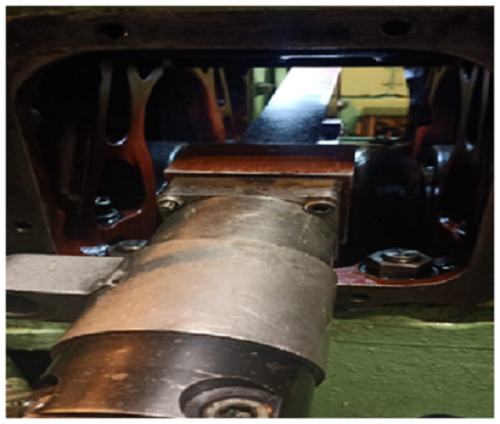

Man B&W 5T23LH, 6L23/30, 9L 27/38, 7L 32/40, 7L 16/24, 9L28/32, 9L25/30, 6L 52/55B crankshafts are successfully repaired by RA Power Solutions for last 42 years.

Ours is the only company in the world which can undertake the repair of Man B&W 5T23LH, 6L23/30, 9L 27/38, 7L 32/40, 7L 16/24, 9L28/32, 9L25/30, 6L 52/55B crankshaft in spite of damage of radius fillet. It is possible to repair the crankshaft on vessel even while sailing.

RA Power Solutions is ISO 9001:2015 (Quality Management System) & ISO 14001:2015 (Environmental Management System) certified approved company having 42 years of experience in undertaking crankshaft repair up to 700 mm diameter.Crank pin and main journal bearings of standard and under size are available in stock.

We have been regularly executing the repairs in Madagascar, Oman, Qatar, Philippines, Bahrain, Srilanka, Bangladesh, Myanmar, Turkey, Nigeria, Greece, Saudi Arabia, UK, Dubai, Malta, Cyprus, Singapore, Malaysia, Colombia, Indonesia, Hong Kong, Spain, Netherlands, Dubai, Portugal, Estonia, Morocco, Belgium, Vietnam, Canada, Jordan, Libya, Kuwait, Egypt, Morocco, Yemen, Bahrain, Tunisia, Sudan, Oman, Algeria, UAE, Iraq.

Visit Us:

http://www.rapowersolutions.com/Blogs.aspx

High-Precision Onsite Grinding

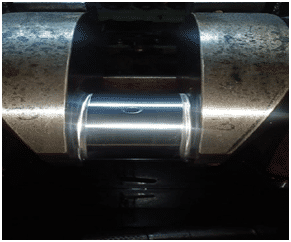

We provide crankshaft grinding with machining accuracy as fine as 0.01 mm directly at your location-ship, vessel, or powerplant. Our advanced tools and mobile equipment enable restoration of crankshafts for MAN B&W engines without removal, ensuring minimal operational disruption and optimal surface finishing as specified by original equipment manufacturer (OEM) requirements.

Certified Quality & OEM Compliance

Every crankshaft repair is executed by trained and certified technical engineers, adhering strictly to MAN B&W OEM standards. We utilize forged high-strength alloy steels (EN24/EN8 or equivalents) and ensure OEM-compatible surface hardness, dimensional accuracy, and concentricity. Detailed inspection for cracks and measurements are performed before and after repair for unrivaled reliability.

Wide Engine Model Coverage

Our service supports a comprehensive range of MAN B&W engine models, including 5T23LH, 6L23/30, 9L27/38, 7L32/40, 7L16/24, 9L28/32, 9L25/30, and 6L52/55B. We accommodate journal diameters from 85 mm to 550 mm, making us an ideal solution for both marine and power plant applications. All solutions are tailored as per the engine's stroke, size, and operating requirements.

FAQ's of Man B&W 5T23LH, 6L23/30, 9L 27/38, 7L 32/40, 7L 16/24, 9L28/32, 9L25/30, 6L 52/55B Crankshaft grinding onsite:

Q: How is the crankshaft grinding process performed onsite for MAN B&W engines?

A: Crankshaft grinding is conducted directly at your vessel or powerplant through specialized portable tools and certified technical engineers. The process begins with crack detection and dimensional checks, followed by precision grinding and polishing to OEM standards, and concludes with another inspection to certify the repair.Q: What engine models are applicable for onsite crankshaft grinding?

A: The service is fully compatible with MAN B&W models 5T23LH, 6L23/30, 9L27/38, 7L32/40, 7L16/24, 9L28/32, 9L25/30, and 6L52/55B. Both standard and customized crankshaft dimensions are supported to meet model-specific requirements.Q: When should onsite crankshaft grinding be considered?

A: Onsite grinding is recommended when wear, scoring, or cracks are detected during scheduled maintenance, or after engine failure. Early intervention restores the crankshaft's precision and hardness, preventing further engine damage and reducing costly downtime.Q: Where can the crankshaft grinding and repair service be provided?

A: The service is available at you ship's engine room, onboard vessels, or at stationary power plants. All equipment is fully portable, allowing repairs to be conducted worldwide without removing the crankshaft from the engine block.Q: What are the main benefits of onsite crankshaft grinding for MAN B&W engines?

A: Onsite crankshaft repair minimizes downtime, reduces logistics costs, and eliminates the need for engine removal. It restores OEM-level precision, extends engine life, and ensures reliable, high-load operation in marine and power plant environments.Q: What is the post-repair quality standard for hardness and surface finish?

A: After repair, the crankshaft achieves a surface hardness of 54-58 HRC and a surface roughness of Ra 0.2 to 0.4 m, both in accordance with MAN B&W OEM standards. Concentricity is guaranteed within 0.02 mm for assured performance.Q: How do you ensure the repaired crankshaft remains compatible with MAN B&W OEM standards?

A: All grinding and polishing processes follow MAN B&W OEM specifications, with inspections performed before and after the job. Each step is handled by certified engineers using high-strength forged alloys, ensuring 100% compatibility, correct dimensions, and required hardness.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in engine spare parts Category

Yanmar Engine 6N18AL-DV, S185L-ST, 6M 220L-SN, 6N21L-SN, 6N330-EN, M200AL-DT, 8N280L-EV, 8EY33LW Crankshaft repair | Crankshaft grinding

Price 1500 USD ($) / Number

Minimum Order Quantity : 1 Number

Head : As per engine specification

Material : Other, Forged Steel / HighGrade Alloy Steel

Power : As per engine rating

Parts Name : Other, Crankshaft

Repair on Vessel of Auxiliary Engine Crankshaft

Price 1600 USD ($) / Number

Minimum Order Quantity : 1 Number

Head : Single Cylinder/Multiple Cylinder Depending on Engine

Material : Other, Forged Steel

Power : Suitable for up to 1200 kW

Parts Name : Other, Auxiliary Engine Crankshaft

MAN Diesel Generator Model no. 9L28/32

Price 1500 USD ($) / Number

Minimum Order Quantity : 1 Number

Head : 9

Material : Other, High Grade Cast Iron & Steel

Power : 3000 kW

Parts Name : Other, Diesel Generator

Crankshaft Grinding Machine Portable - Engineering Revolution

Price 1500 USD ($) / Number

Minimum Order Quantity : 1 Number

Head : Precision Adjustable Grinder Head

Material : Other, High Grade Alloy Steel

Power : Electric 220V, 50Hz

Parts Name : Other, Crankshaft Grinder

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS