Repair of Crack Gearbox by Metal Locking and Metal Stitching

Price 1500 USD ($)/ Number

Repair of Crack Gearbox by Metal Locking and Metal Stitching Specification

- Material

- Cast Iron / Mild Steel / Alloy Steel (as per Gearbox Housing)

- Protection

- Mechanical Bonding and Reinforcement

- Combustion sysytem

- Not Applicable (Mechanical Repair Process)

- Usage

- Repair and reinforcement of cracked gearbox housings

- Condition

- Repair Service

- Dimensions

- Customized as per gearbox requirement

- Weight

- Depends on gearbox size and extent of repair

- Surface Finish

- Machined flush with original surface

- Application Areas

- Gearboxes, Engine Blocks, Transmission Cases, Machinery Components

- Downtime

- Minimal (no need to dismantle equipment in many cases)

- Corrosion Resistance

- Can be paired with protective coatings on request

- Temperature Resistance

- Maintains structural integrity at operational temperatures

- Service Capability

- On-site and workshop repairs available

- Tools Used

- Specialized metallic keys, stitching pins, and cold metal inserts

- Standards

- Complies with industrial repair practices and safety regulations

- Turnaround Time

- Depends on crack length and gearbox type, typically 1-3 working days

- Advantages

- No heat required, preserves base metal, retains alignment, stress-free repair

- Process Warranty

- Available upon request, subject to terms

- Repair Technique

- Metal Locking and Metal Stitching (Mechanical Cold Process)

- Crack Length Capacity

- Effective for small hairline to long through-cracks (custom evaluation)

Repair of Crack Gearbox by Metal Locking and Metal Stitching Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 1 Number Per Day

- Delivery Time

- 2-3 Days

About Repair of Crack Gearbox by Metal Locking and Metal Stitching

RA Power Solutions was approached by a company advising about the damage of Gearbox base manufactured out of cast Iron. This Gearbox is used for the main engine to Propeller shaft. The base was broken into pieces.

The details of damage observations are mentioned below.

|

Sr No. |

Description |

|

|

1 |

Repair of Cracked Gear Box for Main |

|

|

2 |

Length of the cracks Inboard leg |

160 mm |

|

3 |

Length of the cracks Outboard leg |

148 mm |

|

4 |

Thickness of casting cracked |

55 mm |

|

5 |

Engine Make & Model |

Yanmar Model no. YXHG-2500LM |

|

6 |

Place of Execution of Job |

Kandla Port Gujarat |

The thickness of casting was observed as 55mm that is more than 2 inches.

RA Power Solutions undertakes the repair of crack or damaged cast iron, Aluminum, and bronze heavy components by metal stitching or metal locking process which is simple and is a proven process of repair of damage and cracked casting.

Repair of Crack Gearbox by RA Power Solutions technicians:

i) RA Power Solutions deputed two technicians for undertaking inspection and metal stitching of Gearbox.

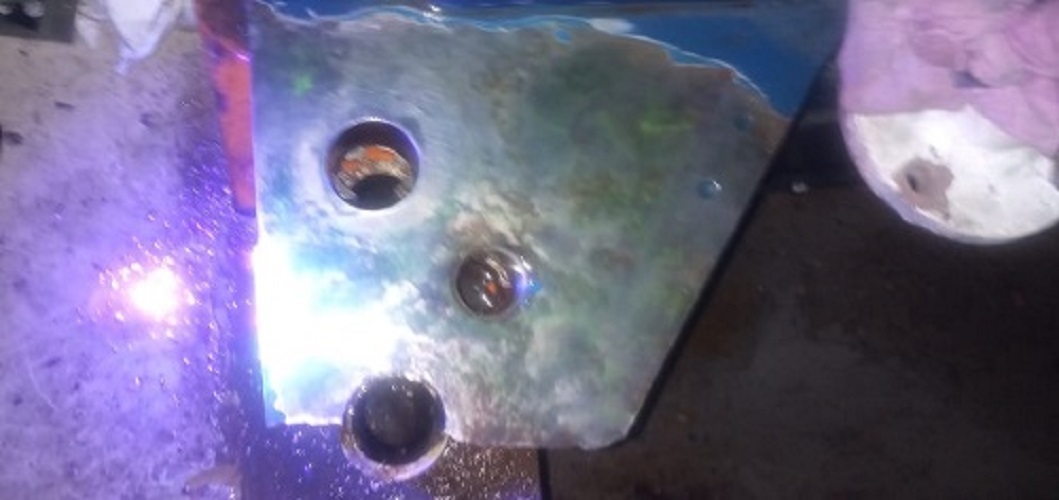

ii) After removal of paint including the Red oxide the cracked area was subject to Dye penetrant inspection and also MPI by high-intensity magnaflux torch to check the location, length and intensity of the cracks.

iii) As mentioned above the cracks measuring 160 mm and 148 mm length were observed.

iv) The thickness of casting was 55 mm which made the repair by metal locking & metal stitching process more difficult.

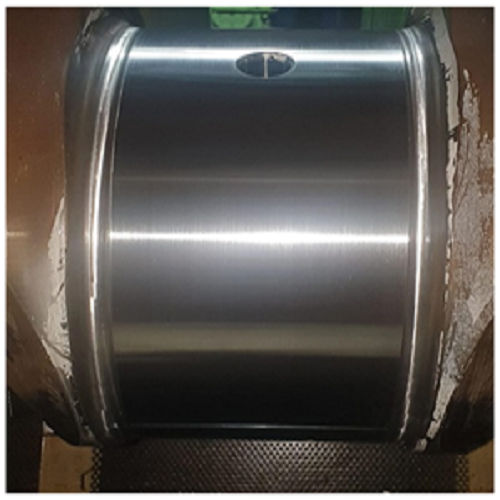

v) Our technicians executed the damage Gearbox repair successfully by using the special master locks, locks and keys.

vi) For details of the process followed by our technicians to undertake the crack repair of gearbox by metal stitching please go through our blogs written in our dedicated website: https://www.metalstitchinglocking.com/

Advantages of Crack Repair by Metal Lock process:

i) The main advantage of crack repair by metal locking & metal stitching is that in majority of cases the crack repair can be executed onsite without dismantling of the equipment. This not only saves the time & money but also saves from the botheration of transportation of heavy components to the workshop.

ii) It is a cold process and does not require any major machining. It is very important in case of repair of engine housing where the requirement of alignment is within 0.03 mm.

iii) No heat is generated hence no distortion.

iv) With the introduction of the latest technology, process and experience of our technicians, we are able to successfully repair the engine major components like cylinder liner, cylinder head, turbocharger casing etc

No-Heat, Stress-Free Gearbox Repairs

Our mechanical cold repair process ensures your gearbox stays intact and stress-free. By utilizing metal locking and metal stitching, we avoid heat, thus preserving the original metal properties and alignment. The finished repair is machined flush with the surface, restoring performance and reliability.

Versatile and Efficient Application

Whether it's cast iron, mild steel, or alloy steel, our repair technique is effective across a range of housing materials and sizes. Capable of handling both short hairline and extensive through-cracks, this method is suitable for gearboxes, engine blocks, transmission cases, and various other machinery components.

Minimal Downtime, Maximum Convenience

We eliminate unnecessary disruptions by offering both onsite and workshop repair options. Our skilled team can typically complete repairs within 1-3 working days depending on the crack length and gearbox type, drastically reducing equipment downtime and restoring functionality quickly.

FAQ's of Repair of Crack Gearbox by Metal Locking and Metal Stitching:

Q: How is metal locking and metal stitching used to repair a cracked gearbox?

A: Metal locking and metal stitching are mechanical cold processes where specialized metallic keys, stitching pins, and inserts are used to bond and reinforce the cracked area without applying heat. The technique restores structural integrity and alignment, and finishes flush with the original surface.Q: What types of cracks and gearbox materials can be repaired using this technique?

A: This method is suitable for a wide range of crack lengths-from small hairline fractures to long through-cracks-in gearbox housings made of cast iron, mild steel, or alloy steel. Each crack is custom evaluated to determine the most effective repair approach.Q: When is it the best time to use this gearbox crack repair service?

A: Our repair service is ideal whenever you identify cracks in your gearbox housing, especially when minimal downtime is critical and heat-based repair methods might cause further damage or distortion. Early intervention helps retain long-term reliability.Q: Where can gearbox crack repairs be performed?

A: Repairs can be carried out both onsite-directly on your equipment-or in our specialized workshops, depending on your requirements and the complexity of the job. Onsite service minimizes equipment movement and related downtime.Q: What is the step-by-step process for repairing a cracked gearbox using this method?

A: After inspecting and evaluating the crack, our specialists install a sequence of metallic keys and stitching pins along the fracture. Cold metal inserts reinforce the repair. The area is then machined to restore a flush surface, and optional protective coatings can be added for corrosion resistance.Q: How does your repair process benefit my operations compared to traditional welding?

A: Unlike welding, our cold repair process generates no heat, eliminating the risk of heat-induced distortion or loss of material properties. The method preserves alignment, avoids internal stresses, and often does not require dismantling the gearbox-resulting in faster turnaround and reduced operational disruption.Q: Is the repair service backed by any warranty or compliant with industrial standards?

A: Process warranties are available upon request, subject to specific terms. All repairs comply with established industrial repair practices and safety regulations to ensure reliable and long-lasting results.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Diesel Engine & Electric Locomotive Spares Category

Daihatsu Diesel Generator 5DC-17, 6DK-20, 6DLB-19, 6DK-28, 6PL-24, 6DL20, 6DS32, 6VSHTC-26D, PSTC 26 & 8P STB 26D Crankpin repair

Price 1500 USD ($) / Number

Minimum Order Quantity : 1 Number

Weight : 6800 kg 23500 kg (model dependent)

Material : Cast Iron Cylinder Block, Alloy Steel Crankshaft

Usage : Marine/Industrial Power Generation

Condition : Other, Brand New/Refurbished

Wartsila VASA 12V32 LN Crankshaft Repair

Price 1500 USD ($) / Number

Minimum Order Quantity : 1 Number

Weight : Approx. 8,500 kg (Crankshaft only)

Material : Forged Steel/Alloy Steel

Usage : Marine, Power plant, Industrial

Condition : Other, Serviced/Overhauled/Repair

Cummins Engine Crankshaft Repair

Price 1500 USD ($) / Number

Minimum Order Quantity : 1 Number

Weight : Approx. 12 kg

Material : Highgrade steel

Usage : Crankshaft repair for Cummins engines

Condition : Other, Repaired

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS