Wartsila VASA 12V32 LN Crankshaft Repair

Price 1500 USD ($)/ Number

Wartsila VASA 12V32 LN Crankshaft Repair Specification

- Usage

- Marine, Power plant, Industrial

- Lubricating System

- Forced lubrication

- Material

- Forged Steel/Alloy Steel

- Fuel Tank Capacity

- Custom/As per plant requirement

- Rated Output

- 3840 kW

- Alternator

- Brushless, Synchronous

- Frequency

- 50/60 Hz

- Combustion sysytem

- Direct Injection

- Protection

- IP23/IP44

- Speed

- 720/750/1000 rpm

- Condition

- Serviced/Overhauled/Repair

- Fuel Type

- HFO/MDO/Marine Diesel

- Stroke

- 350 mm

- Cylinder

- 12 (Vee arrangement)

- Cold Style

- Water Cooled

- Start

- Air or Electric Start

- Dimensions

- Approx. 7,200 mm Length x 1,000 mm Diameter

- Weight

- Approx. 8,500 kg (Crankshaft only)

- Max. Allowable Run-out After Repair

- <0.02 mm

- Journal Diameter

- Approx. 335 mm

- Service Provider

- Certified Marine Engineering Services

- Type of Repair

- On-site/Workshop Crankshaft Repair

- Compliance

- Class Approved Repair (Lloyds, DNV, ABS, etc.)

- Repair Technique

- Crack Detection, Journal Grinding, Polishing, Hardness Testing

- Engine Model

- Wartsila VASA 12V32 LN

- Application Range

- Marine Main Engine, Auxiliary Generator, Power Plants

Wartsila VASA 12V32 LN Crankshaft Repair Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 1 Number Per Day

- Delivery Time

- 2-3 Week

About Wartsila VASA 12V32 LN Crankshaft Repair

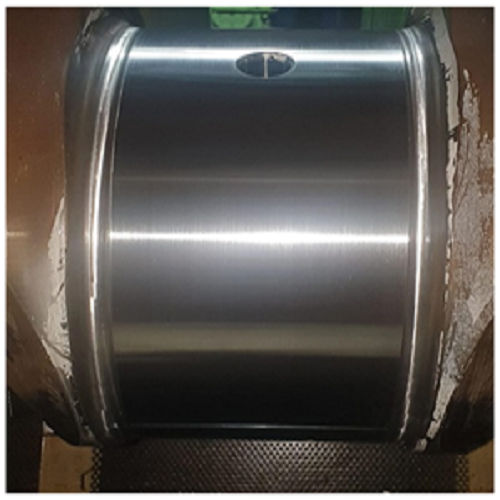

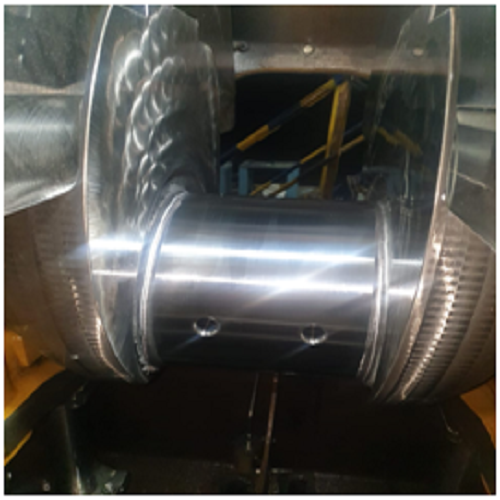

RA Power Solutions offers a cost-effective way to repair Wartsila engine crankshafts. We have the facility to undertake in situ machining of crankshaft having diameters up to 700 mm.

The services are offered for marine, power plants, and other installations worldwide at a very cost-effective rate.

Expert Crankshaft Repair & Compliance

We specialize in repairing and servicing Wartsila VASA 12V32 LN crankshafts, offering both on-site and workshop solutions. All repairs comply with major class requirements (ABS, DNV, Lloyd's), ensuring the highest engineering standards. Our skilled technicians guarantee maximum allowable run-out after repair is less than 0.02 mm, delivering reliability for marine, power plant, and industrial engines.

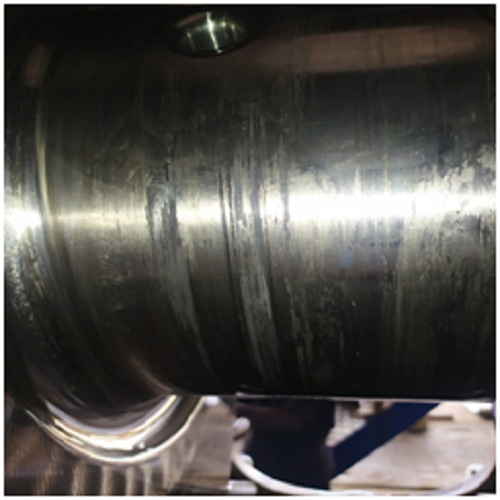

Advanced Detection & Restoration Techniques

Utilizing precision crack detection, journal grinding, polishing, and hardness testing, we provide a complete restoration service for crankshafts. Our approach prevents premature failures and extends equipment service life. The process handles crankshafts up to 7,200 mm length and 1,000 mm diameter, made from forged or alloy steel, tailored for the demands of high-performance engines.

Marine and Power Plant Application Coverage

Our repair service supports primary engine and auxiliary generator needs for a wide range of industries-marine, power plants, and heavy-duty industrial sectors. We accommodate engines running on HFO, MDO, or marine diesel, with outputs up to 3,840 kW and variable speeds (720-1,000 rpm). Service is available for exporters, manufacturers, suppliers, and traders across India.

FAQ's of Wartsila VASA 12V32 LN Crankshaft Repair:

Q: How does the crankshaft repair process for the Wartsila VASA 12V32 LN engine work?

A: Our process starts with thorough crack detection, followed by precise journal grinding and polishing. Hardness testing is performed to ensure the repaired area meets class standards. Repairs can be conducted at your site or at our workshop, ensuring minimal downtime and compliance with marine classification (Lloyd's, DNV, ABS).Q: What applications are covered by your Wartsila VASA 12V32 LN crankshaft repair services?

A: We cover marine main engines, auxiliary generators, and power plant applications. Our services are suited for equipment requiring high reliability, such as vessels, offshore platforms, industrial plants, or any machinery based on the Wartsila VASA 12V32 LN engine.Q: When should I consider crankshaft repair instead of replacement?

A: Crankshaft repair is ideal when cracks, wear, or surface irregularities are detected but don't exceed class repairable limits. Repair is a cost-effective and time-saving alternative to full replacement, especially when you need to restore function quickly to minimize operational disruption.Q: Where can you perform the crankshaft repair?

A: Repairs can be carried out on-site at your engine's location or in our fully-equipped workshop, depending on your needs and the extent of the repair required. This flexibility accommodates marine vessels, remote plants, and industrial installations.Q: What is the maximum allowable journal run-out after repair?

A: Post-repair, our technicians ensure the crankshaft run-out does not exceed 0.02 mm, meeting strict OEM and classification society standards for engine safety and performance.Q: How do I benefit from choosing certified marine engineering services for crankshaft repair?

A: Certified services ensure your repair meets global quality and safety standards. You benefit from rigorous inspection, compliance with class requirements, reduced downtime, and extended crankshaft lifecycle, helping you maintain operational reliability and regulatory approval.Q: What types of certification or class approvals do you comply with after a crankshaft repair?

A: We ensure all repairs are certified by major classification societies, including Lloyd's Register, DNV, and ABS, providing you with documentation for continued safe operation and compliance with maritime regulations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Diesel Engine & Electric Locomotive Spares Category

Daihatsu Diesel Generator 5DC-17, 6DK-20, 6DLB-19, 6DK-28, 6PL-24, 6DL20, 6DS32, 6VSHTC-26D, PSTC 26 & 8P STB 26D Crankpin repair

Price 1500 USD ($) / Number

Minimum Order Quantity : 1 Number

Condition : Other, Brand New/Refurbished

Dimensions : 4350x1500x2450 mm to 8300x2450x4100 mm (LxWxH)

Usage : Marine/Industrial Power Generation

Weight : 6800 kg 23500 kg (model dependent)

Repair of Crack Gearbox by Metal Locking and Metal Stitching

Price 1500 USD ($) / Number

Minimum Order Quantity : 1 Number

Condition : Other, Repair Service

Dimensions : Customized as per gearbox requirement

Usage : Repair and reinforcement of cracked gearbox housings

Weight : Depends on gearbox size and extent of repair

Cummins Engine Crankshaft Repair

Price 1500 USD ($) / Number

Minimum Order Quantity : 1 Number

Condition : Other, Repaired

Dimensions : Standard Dimensions

Usage : Crankshaft repair for Cummins engines

Weight : Approx. 12 kg

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS