Grinding of Crank Pin of Daihatsu Engine

Price 1500 INR/ Square Inch

Grinding of Crank Pin of Daihatsu Engine Trade Information

- Minimum Order Quantity

- 1 , , Square Inch

- Supply Ability

- 1 , , Square Inch Per Day

- Delivery Time

- 2-3 Days

About Grinding of Crank Pin of Daihatsu Engine

We were approached by a ship management company based in Athens, Greece having ninety vessels regarding breakdown of the crankshaft of Daihatsu Engine 5DK-20.

The engine & crankshaft details are given below:

|

S. NO |

Crankshaft Details |

|

|

1 |

Engine Make |

Daihatsu |

|

2 |

Engine Model |

5DK-20 |

|

3 |

Crankpin Diameter Standard |

170 mm |

|

4 |

Crankpin Bearing Width |

78 mm |

|

5 |

Place of Execution of Job |

Navlakhi Port (INDIA) |

RA Power Solutions team of two technicians with portable crankshaft repair equipment was immediately deputed to Navlakhi Port in western part of India. On inspection of crankshaft following was observed:

Main observations of the crankshaft of Daihatsu Engine 5DK-20 after inspection:

i) The crankpin no. 3 was badly damaged due to seizure of the bearing. The bearing white metal was badly embedded on the crankpin diameter.

ii) On visual inspection it was observed that the radius fillet of both sides was damaged and original profile of radius fillet was lost.

iii) After removal of bearing material from the crankpin diameter deep scoring marks and multiple depressions were observed.

vi)The crankpin was subject to MPI test for crack detection, multiple cracks were observed having length ranging from 3.0 mm to 19 mm. All the cracks were hairline cracks.

v) Hardness was taken and was found on the higher side even up to 515 BHN. This was the scattered hardness.

vi) Deflection of complete crankshaft was checked and was observed within limits.

Rejection of crankshaft by reputed Singapore based crankshaft repair companies

The damaged crankshaft of Daihatsu 5DK-20 was inspected by three leading crankshaft repair companies based in Singapore who rejected the crankshaft and declared it beyond repair on site because of following reasons:

i) The crank pin of Daihatsu 5DK-20 diameter is 170mm and the bearing width is only 78 mm. The companies in Singapore don't have the equipment which can be placed on the crank pin with small bearing width for on site grinding purpose.

ii) Since both sides of the radius fillet were damaged they insisted on removal of the crankshaft from the engine block and sending it to the workshop for repair if possible.

iii) The presence of multiple cracks and higher hardness of crankpin was also one of the reasons for rejection of the crankshaft.

Successful repair executed by RA Power of Daihatsu engine 5DK-20 crankshaft with damaged radius fillet

RA Power Solutions technicians successfully repaired the radius fillet of both sides and executed the grinding of crank pin no.3 to the under size of 2.0 mm.

All the parameters were checked after crankshaft repair as per the International standard and manufacturer manual and were observed within limits.

RA Power Solutions is the International leader in repair of crankshaft up to 700 mm diameter. We are the only company in the world which manufacture & supply on site crankshaft repair equipment.

For your requirement of repairing the crankshaft, crankshaft with damaged radius fillet on the vessel or anywhere in the world please contact us.

Precision Grinding for Daihatsu Marine Diesel Engines

Our service specializes in high-precision grinding of crank pins for Daihatsu marine diesel engines. We utilize advanced portable onsite grinding machines operated by skilled technicians, ensuring minimal downtime. Each process achieves strict tolerances as low as 0.015 mm and improves crank pin hardness up to 62 HRC. Engine reliability and fuel efficiency are enhanced, complying with global quality standards for marine applications.

Comprehensive Inspection and Documentation

Every grinding operation comes with detailed post-job inspection reports, dimensional certificates, and hardness test reports. Our quality assurance includes non-destructive testing (NDT), ensuring the repaired crank pin meets exacting standards. Clients receive clear documentation for compliance and maintenance records, offering full transparency and peace of mind after each job.

FAQ's of Grinding of Crank Pin of Daihatsu Engine:

Q: How is the grinding of Daihatsu engine crank pins performed onsite?

A: Expert engineers use a portable onsite crankshaft grinding machine to restore the crank pin's diameter and surface properties directly on the vessel, minimizing engine downtime and transport costs.Q: What are the benefits of achieving a surface finish up to Ra 0.2 micron and hardness up to 62 HRC?

A: A superior surface finish reduces friction and wear, while increased hardness enhances the crank pin's durability. This combination results in improved engine performance and extended component life for marine operations.Q: When can I expect completion of crank pin grinding for my Daihatsu engine?

A: Turnaround time is typically 48 to 72 hours, depending on the crank pin's condition. Our worldwide, 24/7 service ensures fast response to urgent marine repair requirements.Q: Where is your crank pin grinding service available?

A: Our service is available both onsite and at workshops worldwide. We dispatch technicians anywhere vessels require maintenance, ensuring quick support and expert repairs at your location.Q: What process controls and inspection methods are employed during crank pin grinding?

A: We adhere to ISO 9001:2015 quality standards, using non-destructive testing (NDT) and dimensional analysis throughout the grinding process. Comprehensive inspection and documentation guarantee each repair's reliability.Q: How can I use your documentation provided after crank pin grinding?

A: Post-job inspection reports, dimensional certificates, and hardness test results may be used for internal quality audits, maintenance records, and regulatory compliance, ensuring full transparency of the repair and its results.Q: What makes your service suitable for marine and ship engine applications?

A: Our grinding service addresses the strict precision, durability, and reliability requirements of marine diesel engines, utilizing high alloy steels and advanced machining techniques to support ship engine repair and overhauling globally.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Crankshaft Repair Category

Onsite Crankshaft Grinding Machine

Price 300000 INR / Square Inch

Minimum Order Quantity : 1 , , Square Inch

Repair of Crankshaft of MAN B&W Engine Model no. 5L 16/24

Price 1500 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

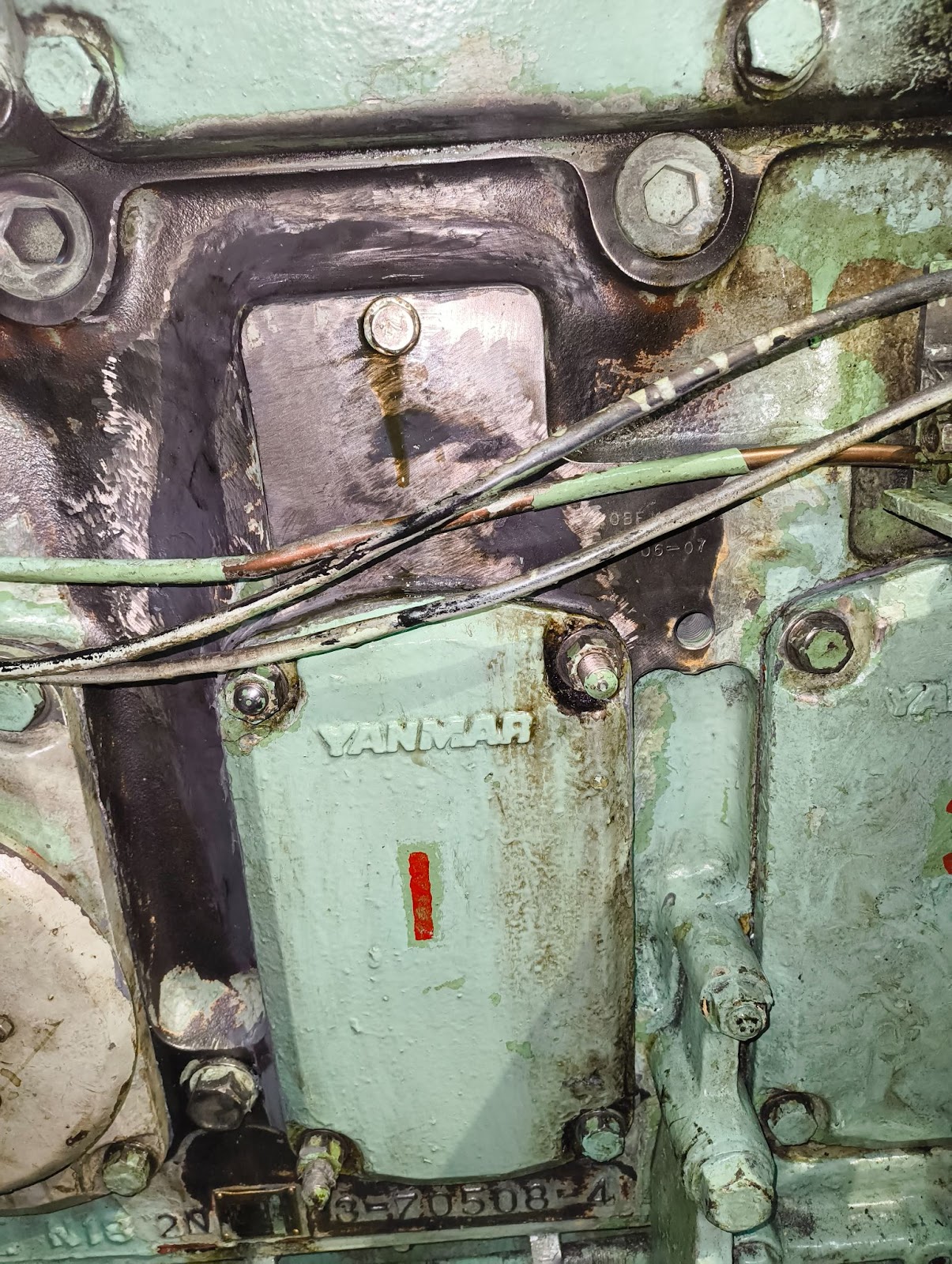

YANMAR 6N18L-SV Auxiliary Engine Crankshaft

Price 1000.0 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

MAN 9 ASL 25/30 Crankshaft Repair/in situ Crankshaft Grinding RA Power Solutions

Price 1500 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS