Rolls Royce Engine Crankshaft Grinding Onsite

Price 1500 INR/ Square Inch

Rolls Royce Engine Crankshaft Grinding Onsite Specification

- Technician Qualification

- OEM Certified Engineers

- Emergency Response Time

- 24-48 Hours

- Repair Documentation

- Certificate Provided After Completion

- Inspection Standard

- Conforms to Major Classification Societies

- Environmental Compliance

- Dust and Debris Collection System Used

- Maximum Journal Diameter

- Up to 700 mm

- Surface Finish After Grinding

- 0.15 Ra or better

- In-situ Grinding Accuracy

- 0.02 mm (20 microns)

- Onsite Repair Capability

- Worldwide Deployment

- Minimum Journal Diameter

- 60 mm

- Operating Hours

- Available 24/7 Upon Request

- Equipment Used

- Portable Crankshaft Grinding Machine

Rolls Royce Engine Crankshaft Grinding Onsite Trade Information

- Minimum Order Quantity

- 1 Square Inch

- Supply Ability

- 1 Square Inch Per Day

- Delivery Time

- 2-3 Days

About Rolls Royce Engine Crankshaft Grinding Onsite

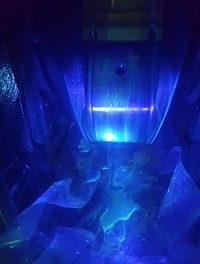

We were approached by our old client who informed about the damage to the crankshaft of Bergen Rolls Royce make of Engine model C 25:33 L9P.

The Detail of Engine,Crankpin diameter and bearing width are mentioned below in the box:

|

S. NO |

Crankshaft Details |

|

|

1 |

Engine Make |

Bergen Rolls Royce |

|

2 |

Engine Model |

C 25:33 L9P |

|

3 |

Crank pin Diameter Standard |

230 mm |

|

4 |

Crankpin Bearing Width |

92 mm |

|

5 |

Place of execution of crankshaft repair |

Mumbai Port, India |

Action taken by RA Power Solutions to Repair Bergen Rolls Royce Crankshaft Model no. C 25:33 L9P

i) Before the arrival of our two technicians and boarding on a vessel at Mumbai Port India, the ship staff removed all the connecting rods.

ii) On visual inspection one number of crankpin was observed damaged having standard diameter of 230 mm and crank pin bearing width of 92 mm.

The minimum & maximum reading of crank pin was observed as following:

a) Minimum diameter observed- 229.61 mm

b) Maximum diameter observed- 229.93 mm

Against the standard diameter of 230.00 mm the ovality of 0.32 mm was observed which is considered to be very much on the higher side. Deep bearing line Marks and rough surface was observed.

iii) All other crankpins were also subject to dimensional inspection, taper & ovality was observed within limits. Only the Bearing line marks were observed.

iv) As a routine inspection the hardness of crankpin was inspected and was observed within limits. The crack detection was also undertaken by MPI and no crack was observed.

v) The grinding of one number of crank pin was undertaken maintaining the final size of 229.00 mm with undersize of 1.0 mm.

vi) All other crankpins were polished for removal of bearing line marks. After polishing the surface finish of better than 0.15 RA Value was observed.

Successful Repair of Bergen Rolls Royce Crankshaft Model no. C 25:33 L9P

i) RA Power Solutions is ISO 9001:2015 (Quality Management System) & ISO 14001:2015 (Environmental Management System) certified approved company having global presence and executing successfully repair of medium & large crankshafts diameter ranging from 30mm to 700 mm.

ii) We have a team of experienced technicians who are factory trained and ready to fly to any site all over the world with equipment in a short notice.

iii) All our technicians have valid Indian CDC.

iv) We are regularly extending our services to Marine, Power Plant and heavy industries all over the world.

v) RA Power Solutions with 41 years of experience in the field of crankshaft repair have developed the equipment & procedure of crankshaft repair which is of high quality & cost effective.

vi) We are perhaps the lowest in cost in comparison to the companies in UK, Europe and other countries.

vii) In most of the cases our response time is immediate to meet with any emergency requirement of crankshaft grinding.

Precision Onsite Grinding for Large Crankshafts

Our expert team employs advanced portable grinding technology to restore crankshaft journals onsite, accommodating diameters between 60 to 700 mm. This precision service achieves a remarkable 0.02 mm (20 microns) grinding accuracy and a surface finish of 0.15 Ra or better, ensuring optimal performance and longevity of your Rolls Royce engine.

Expert Engineers and Worldwide Reach

All onsite crankshaft grinding is carried out by OEM certified engineers, trained to meet strict industry benchmarks. Our team is available 24/7 for emergency deployments worldwide, guaranteeing minimal operational downtime. We adhere to major classification society standards, providing full repair certification upon completion.

FAQs of Rolls Royce Engine Crankshaft Grinding Onsite:

Q: How is onsite crankshaft grinding for Rolls Royce engines performed?

A: Onsite crankshaft grinding uses a portable grinding machine to repair and restore journal surfaces directly in the engine housing. This eliminates the need for disassembling and transporting the crankshaft, ensuring quicker and more efficient repairs.Q: What is the maximum and minimum journal diameter that can be serviced?

A: We can service crankshaft journals with diameters ranging from as small as 60 mm up to a maximum of 700 mm, accommodating a wide range of Rolls Royce engine models.Q: When can I expect a response for emergency crankshaft repair?

A: Our specialized team is ready to deploy within 24 to 48 hours of your emergency request, offering rapid worldwide service to minimize downtime and restore engine function swiftly.Q: Where are your onsite grinding services available?

A: We provide global deployment of our onsite crankshaft grinding services. Our technicians travel worldwide, reaching your industrial, marine, or power plant location as required.Q: What are the benefits of in-situ crankshaft grinding over traditional repair methods?

A: In-situ crankshaft grinding saves time and costs by eliminating the need for crankshaft removal and shipping. It delivers highly accurate restoration (up to 0.02 mm) with minimal interruption to your operations, all while adhering to strict environmental and quality standards.Q: Does your repair process comply with industry regulations?

A: Yes, our onsite grinding process meets the requirements of major classification societies and environmental standards. We use a dust and debris collection system and provide full certification upon completion of repairs.Q: Who performs the onsite crankshaft repairs?

A: All repairs are conducted by engineers who are certified by the original equipment manufacturer (OEM) for Rolls Royce engines, ensuring reliable workmanship and compliance with industry best practices.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Crankshaft Repair Category

Insitu And Onsite Crankshaft Journal Repair/ Crankshaft Grinding/ RA Power Solutions

Price 1500 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Repair of Crankshaft of MAN B&W Engine Model no. 5L 16/24

Price 1500 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS