Babbitt White Metal Alloy Manufacturer

Price 3500 USD ($)/ Piece

Babbitt White Metal Alloy Manufacturer Specification

- Lubrication Type

- Oil Lubricated

- Inside Diameter

- Custom

- Precision Rating

- ISO Standard

- Thickness

- Custom

- Bearing Type

- White Metal Babbitt Bearing

- Material

- Babbitt White Metal Alloy

- Structure

- Plain, Solid

- Number Of Rows

- Single

- Bore Size

- Custom

- Outside Diameter

- Custom

- Load Capacity

- High

Babbitt White Metal Alloy Manufacturer Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 2-3 Days

- Certifications

- ISO 9001:2015 SEPC

About Babbitt White Metal Alloy Manufacturer

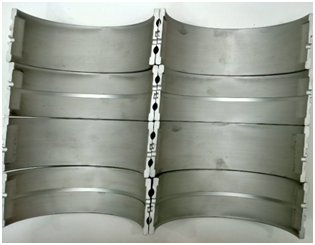

White Metal Babbitt was introduced about 180 years back and over time, it has been improved with the presence of tin, copper and antimony. RA Power Solutions manufactures white metal/ Babbitt white metal alloy according to the international norms or as per the customized requirement of Babbitt white metal of the client.

THE MAIN ADVANTAGES OF WHITE METAL/ BABBITT WHITE METAL ALLOY:-

- The white metal has lower wear.

- High friction resistance.

- Better absorption of lubricant and foreign particles.

- APPLICATIONS OF WHITE METAL/ BABBITT WHITE METAL ALLOY:-

- Babbitt white metal is used as lining for bearing shells which are made out of cast iron, bronze or steel.

The Babbitt lining of bearing helps in preventing friction and wear which enhances the life of the bearing manifolds.

Babbitt metal is preferred for steady load conditions with application for electrical motor, pumps, blowers, turbines, engines, compressors, etc.

CHEMICAL COMPOSITION (%) CHART

| INDUSTRY NAME | Sn (Tin) | Sb (Antimony) | Cu (Copper) | Pb (Lead) |

| Marine 11 D | 90.0 -92.0 | 4.5 -5.5 | 3.5 -4.5 | 0.2 (Max) |

| No. 1 | 90.0 -92.0 | 4.0 -5.0 | 4.0 -5.0 | 0.2 (Max) |

| Marine 11 R | 89.0 -89.5 | 7.5 -8.5 | 2.5 -3.0 | 0.2 (Max) |

| Nickel Genuine | 88.0 -90.0 | 7.0 -8.0 | 3.0 -4.0 | 0.2 (Max) |

| Marine 11 | 88.0 -90.0 | 5.5 -6.0 | 5.0 -5.5 | 0.2 (Max) |

| Maximum Allowable Impurities: | Fe=0.08, As=0.10, Bi=0.08, Zn=0.005, Al=0.005, Cd=0.05 | |||

Engineered Durability for Heavy-Duty Applications

Our Babbitt White Metal Alloy Bearings are crafted to withstand rigorous operating conditions, supporting heavy loads in industrial machinery, automotive systems, and marine equipment. Made through precise casting, these bearings deliver high structural integrity, reliable performance, and a smooth operational finish, even under demanding environments.

Custom Solutions to Fit Your Needs

Understanding that every application has unique requirements, we offer customization for bore size, outside and inside diameter, and bearing thickness. Work with our engineering team to specify the exact dimensions and features best suited for your machinery, ensuring optimal fit and longevity.

Exceptional Performance and Compliance

Adhering to ASTM B23 and ISO precision standards, our Babbitt bearings offer excellent corrosion resistance, operate efficiently up to 150C, and are oil lubricated for sustained smoothness. Each product is thoroughly tested to maintain high load capacity and reliability over extended usage cycles.

FAQ's of Babbitt White Metal Alloy Manufacturer:

Q: How are Babbitt White Metal Alloy Bearings manufactured?

A: These bearings are produced through a precision casting process, ensuring uniform density and excellent mechanical properties. The method provides a smooth finish and allows for custom dimensions as per project requirements.Q: What are the primary applications for your Babbitt bearings?

A: Our bearings are designed for use in industrial machinery, automotive components, and marine engines, where high load capacity, durability, and corrosion resistance are essential for reliable performance.Q: When should I consider using a Babbitt White Metal Alloy Bearing?

A: Babbitt bearings are ideal for applications requiring high load support, excellent corrosion resistance, and consistent operation at temperatures up to 150C, especially where custom sizing and a solid, single-row structure are needed.Q: Where are these white metal bearings supplied from?

A: We manufacture, export, and supply our Babbitt White Metal Alloy Bearings from India, delivering to clients across various sectors both domestically and internationally.Q: What is the benefit of customizing the bore and diameter dimensions?

A: Customization ensures that each bearing precisely matches your machinery's specifications, leading to improved performance, reduced wear, and extended equipment lifespan.Q: How does the oil lubrication system benefit these bearings?

A: Oil lubrication minimizes friction and heat build-up, helping sustain smooth motion and prolonging the life of the bearing even under continuous operation.Q: What standards and compliance measures do these bearings meet?

A: All bearings are manufactured in compliance with ASTM B23 for material quality and precision, as well as ISO standards for accuracy and reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in White Metal Bearing Category

White Metal Babbitt Bearing

Price 3000-90000 USD ($) / Piece

Minimum Order Quantity : 1 , , Piece

Inside Diameter : Custom

Structure : Split

Precision Rating : ISO Standards

Number Of Rows : Other, Single

Tri Metal Bearing

Price 1500 USD ($) / Number

Minimum Order Quantity : 1 , , Number

Inside Diameter : 30 mm

Structure : Tri Metal

Precision Rating : P5

Number Of Rows : Single Row

Trimetal Bearing

Price 3100 USD ($) / Piece

Minimum Order Quantity : 1 Piece

Inside Diameter : 35 mm

Structure : Trimetal

Precision Rating : P6

Number Of Rows : Single Row

Rebabbitting Of Old Bearing

Price 3200 USD ($) / Piece

Minimum Order Quantity : 1 , , Piece

Inside Diameter : Custom as per requirement

Structure : Split Type

Precision Rating : ISO Standard

Number Of Rows : Other, Single

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS